,

Playing around in MatchBot, I doubled the exhaust/muffler system backpressure to see what it did to the exhaust manifold pressure. The MatchBot data with the EFR6258 shows the turbine pressure ratio goes from 2 to 2.5. Increasing the exhaust back pressure by 2psi at 6000rpm increased the exhaust manifold pressure by 5psi because the turbine is operating at a pressure ratio of 2.5 at that engine speed. The engine delta pressure went from -7psi to -12psi in this match.

Playing around in MatchBot, I doubled the exhaust/muffler system backpressure to see what it did to the exhaust manifold pressure. The MatchBot data with the EFR6258 shows the turbine pressure ratio goes from 2 to 2.5. Increasing the exhaust back pressure by 2psi at 6000rpm increased the exhaust manifold pressure by 5psi because the turbine is operating at a pressure ratio of 2.5 at that engine speed. The engine delta pressure went from -7psi to -12psi in this match.

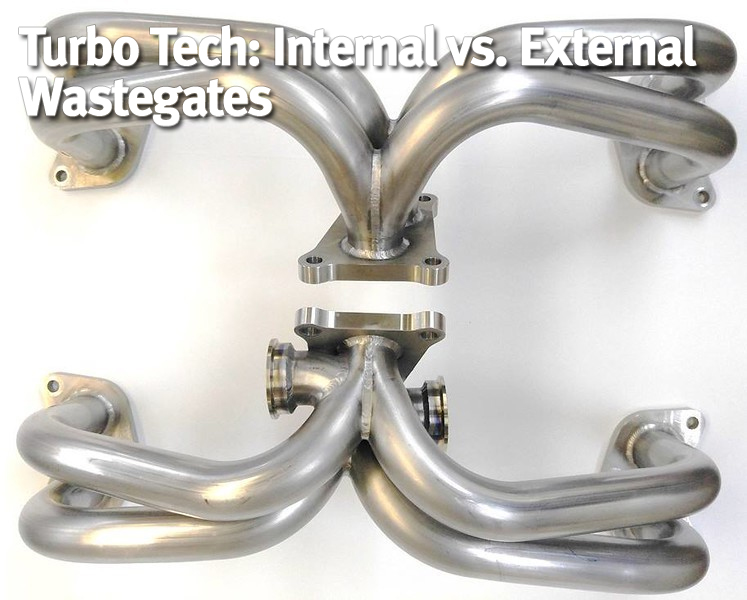

Bren Tuning had a WRX in the house and tested both headers from Killer B Motorsport: the one which kept the internal wastegate of the stock turbo and the twin external wastegate version.

Bren Tuning had a WRX in the house and tested both headers from Killer B Motorsport: the one which kept the internal wastegate of the stock turbo and the twin external wastegate version.

The Killer B Motorsport header with external wastegates for the 2015+ WRX dumps the flow from the wastegates for essentially zero back pressure.

The Killer B Motorsport header with external wastegates for the 2015+ WRX dumps the flow from the wastegates for essentially zero back pressure.

Here is the link to Bren Tuning’s thread on their testing for full information:

https://forums.nasioc.com/forums/showthread.php?t=2803482

Using an external wastegate and dumping the wastegate flow is an easy power gain compared to using the internal wastegate. You may be wondering what the performance difference would be if you plumbed the external wastegate flow back into the exhaust. There are a lot of ‘it depends’ in the answer. If the wastegate flow is plumbed back into the exhaust after the catalytic converter, then there will be significant gains because the cat is a big flow restriction. If the wastegate flow also goes through the cat, there is still opportunity for an external gate setup to perform better than an internally wastegated setup.

Internally wastegated turbos reintroduce the wastegate flow right after the turbine wheel. Due to packaging space limitations, it is difficult to reintroduce the flow in an optimized manner where the wastegate flow would be smoothly merged. Therefore, the wastegate flow can become a bit of a flow hindrance to the exhaust flow exiting the turbine wheel and increase the back pressure. That’s not to say the OEMs don’t try to optimize the flow, they do try to tweak the wastegate and turbine housing geometry to minimize the impact, but there’s a limit to what the engineers can do within the given packaging constraints.

Internally wastegated turbos reintroduce the wastegate flow right after the turbine wheel. Due to packaging space limitations, it is difficult to reintroduce the flow in an optimized manner where the wastegate flow would be smoothly merged. Therefore, the wastegate flow can become a bit of a flow hindrance to the exhaust flow exiting the turbine wheel and increase the back pressure. That’s not to say the OEMs don’t try to optimize the flow, they do try to tweak the wastegate and turbine housing geometry to minimize the impact, but there’s a limit to what the engineers can do within the given packaging constraints.