,

The original OMSE spec motor had a simple dry sump pan that capped off the bottom of the motor. The main bearing caps were production individual pieces. mountune changed this so the main bearing caps are integrated into the LM25 alloy oil pan and bolted to the block's deep skirts. This greatly stiffens the block much like how a bed plate would which is essential for improving everything from head and ring sealing to bearing life. Unlike many modern race engines with individually scavenged crankshaft bays, the mountune engine uses an open sump and an Auto Verdi dry sump pump with two scavenge stages and one pressure stage, pretty simple. The oil pan also contains 3 oil jets per cylinder for piston oil cooling, essential for the high combustion pressures and temps this engine runs at.

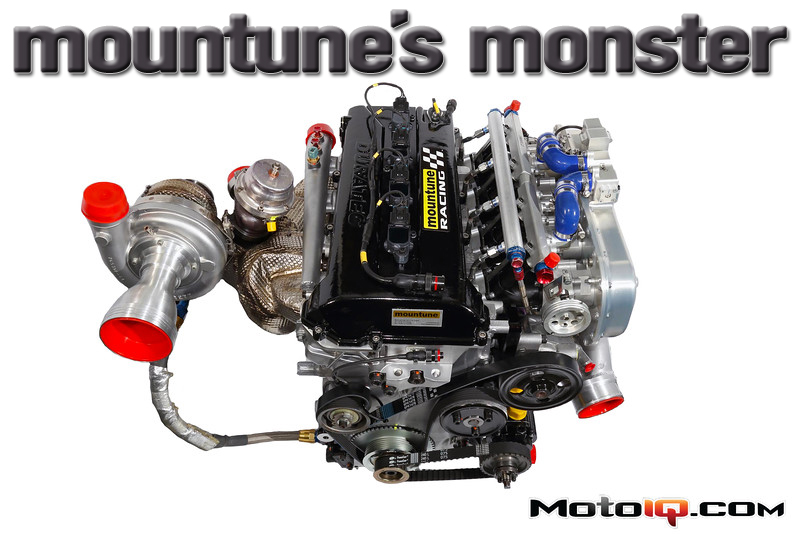

The original OMSE spec motor had a simple dry sump pan that capped off the bottom of the motor. The main bearing caps were production individual pieces. mountune changed this so the main bearing caps are integrated into the LM25 alloy oil pan and bolted to the block's deep skirts. This greatly stiffens the block much like how a bed plate would which is essential for improving everything from head and ring sealing to bearing life. Unlike many modern race engines with individually scavenged crankshaft bays, the mountune engine uses an open sump and an Auto Verdi dry sump pump with two scavenge stages and one pressure stage, pretty simple. The oil pan also contains 3 oil jets per cylinder for piston oil cooling, essential for the high combustion pressures and temps this engine runs at. The mountune speced crankshaft is carved from nitrided EN40B steel alloy by Arrow and features full counterweights. The superfinished journals are 58mm in the mains up from the stock 52mm while the rods are 48mm up from the stock 47mm. The stroke is 84mm up from the stock stroke of 83.1mm. The larger journals allow for more bearing area to support the huge combustion pressures the engine produces and to stiffen the crankshaft with much more journal overlap. The engine bearings are tri-metal parts made by Clevite. With bigger journals and full counterweighting, no torsional damper is needed and the engine runs without one.

The mountune speced crankshaft is carved from nitrided EN40B steel alloy by Arrow and features full counterweights. The superfinished journals are 58mm in the mains up from the stock 52mm while the rods are 48mm up from the stock 47mm. The stroke is 84mm up from the stock stroke of 83.1mm. The larger journals allow for more bearing area to support the huge combustion pressures the engine produces and to stiffen the crankshaft with much more journal overlap. The engine bearings are tri-metal parts made by Clevite. With bigger journals and full counterweighting, no torsional damper is needed and the engine runs without one. The rods are also custom made by Arrow to mountune's specifications from a new alloy called M2000. The rods have a much larger big end to accommodate the larger rod bearings. The rods are an I-beam design and are very beefy as you can see in this picture to withstand the pounding of the high combustion pressures this engine produces. The rod bolts are 3/8″ ARP UNF custom age multiphase steel. The rod small end bushing is made from hard phosphor bronze. There is no special provision for piston pin oiling. With 3 oil jets per cylinder additional pin oiling was deemed to be unnecessary.

The rods are also custom made by Arrow to mountune's specifications from a new alloy called M2000. The rods have a much larger big end to accommodate the larger rod bearings. The rods are an I-beam design and are very beefy as you can see in this picture to withstand the pounding of the high combustion pressures this engine produces. The rod bolts are 3/8″ ARP UNF custom age multiphase steel. The rod small end bushing is made from hard phosphor bronze. There is no special provision for piston pin oiling. With 3 oil jets per cylinder additional pin oiling was deemed to be unnecessary. The forged pistons are built to mountune's specs by JE. The pistons use an old school full skirted design as modern strut pistons were deemed not to have enough support for super high boost operation. The pistons are made of tough low silicon 2618 alloy. mountune tweaked the piston dish from the old OMSE design for better flame front propagation which allowed them to get away with more ignition timing. The compression ratio stands at a relatively high10.5:1. The piston skirts are coated with a dry film lubricant. The piston is unique in that it uses a thicker NPR 1.5mm top ring and a thinner 1.2mm Napier second ring. This is because the top ring takes a huge beating from the high combustion pressure. The steel rings including the oil ring rails are coated with titanium nitride for low fiction and long wear. The rings have horizontal gas ports for better sealing. The 22mm straight wall JE piston pin is a much thicker spec than the early OMSE design for less flex and stress on the pin bosses and the small end of the rod.

The forged pistons are built to mountune's specs by JE. The pistons use an old school full skirted design as modern strut pistons were deemed not to have enough support for super high boost operation. The pistons are made of tough low silicon 2618 alloy. mountune tweaked the piston dish from the old OMSE design for better flame front propagation which allowed them to get away with more ignition timing. The compression ratio stands at a relatively high10.5:1. The piston skirts are coated with a dry film lubricant. The piston is unique in that it uses a thicker NPR 1.5mm top ring and a thinner 1.2mm Napier second ring. This is because the top ring takes a huge beating from the high combustion pressure. The steel rings including the oil ring rails are coated with titanium nitride for low fiction and long wear. The rings have horizontal gas ports for better sealing. The 22mm straight wall JE piston pin is a much thicker spec than the early OMSE design for less flex and stress on the pin bosses and the small end of the rod. The OMSE cylinder head is a bespoke design and deviates quite a bit from the production part. The intake ports are raised for more flow with the contour as such to promote tumble flow into the combustion chamber instead of swirl like the stock ports. The exhaust ports are greatly different as the stock ports are asymmetrical with the outer valves having a much longer curved flow path. The OMSE exhaust ports are straight and symmetrical for greatly improved flow characteristics. Supertech stainless steel intake valves are 35mm in diameter, 1mm smaller than the stock 36mm parts. The Supertech exhaust valves are made from Inconel and are 32mm vs the stock 31mm. These valve area to bore size ratios were determined by mountune to be better. The valve seats are beryllium copper for heat resistance and improved valve cooling. Arrow supplied the spring buckets and the dual valve springs with light interference for better damping of spring surge are made by PAC. The cooling system is totally different with an external water jacket and true cross flow through the head of coolant for much improved combustion chamber cooling. The included valve angle is the same as stock or 39 degrees which is sort of a lot for a modern race engine but mountune feels that this is OK for a turbo engine. Camshafts are a mountune spec ground on iron billets by Piper Cams and the cams are driven by an IWIS full roller chain instead of the OEM silent type chain. The OEM hydraulic chain tensioner is replaced with a mechanical roller as the hydraulic tensioner compresses if a spin forces the engine to spin backwards. This can cause the chain to jump timing.

The OMSE cylinder head is a bespoke design and deviates quite a bit from the production part. The intake ports are raised for more flow with the contour as such to promote tumble flow into the combustion chamber instead of swirl like the stock ports. The exhaust ports are greatly different as the stock ports are asymmetrical with the outer valves having a much longer curved flow path. The OMSE exhaust ports are straight and symmetrical for greatly improved flow characteristics. Supertech stainless steel intake valves are 35mm in diameter, 1mm smaller than the stock 36mm parts. The Supertech exhaust valves are made from Inconel and are 32mm vs the stock 31mm. These valve area to bore size ratios were determined by mountune to be better. The valve seats are beryllium copper for heat resistance and improved valve cooling. Arrow supplied the spring buckets and the dual valve springs with light interference for better damping of spring surge are made by PAC. The cooling system is totally different with an external water jacket and true cross flow through the head of coolant for much improved combustion chamber cooling. The included valve angle is the same as stock or 39 degrees which is sort of a lot for a modern race engine but mountune feels that this is OK for a turbo engine. Camshafts are a mountune spec ground on iron billets by Piper Cams and the cams are driven by an IWIS full roller chain instead of the OEM silent type chain. The OEM hydraulic chain tensioner is replaced with a mechanical roller as the hydraulic tensioner compresses if a spin forces the engine to spin backwards. This can cause the chain to jump timing.