,

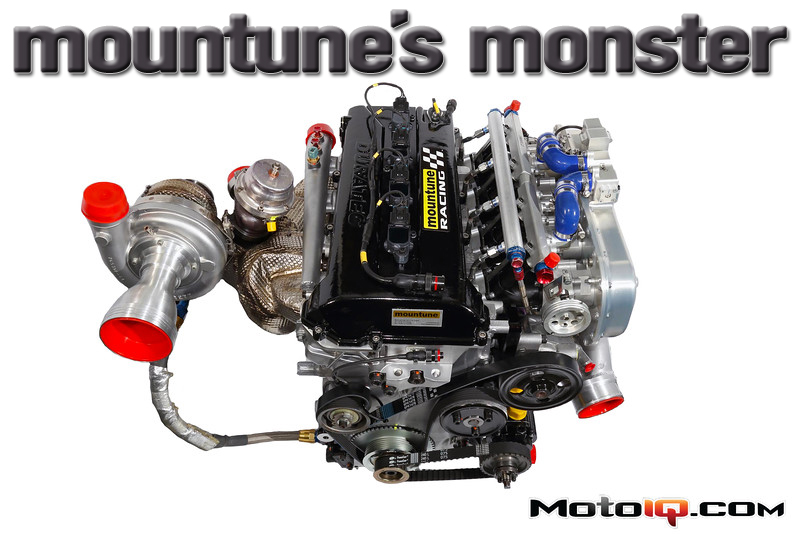

The turbo used on the mountune GRC engine is a variation of the legendary Garrett TR30R Motorsports turbo. The TR30R uses bespoke mountune wheels optimized for use with high boot and a lot of inlet restriction due to the mandated 45mm restrictor. mountune also speced an exhaust housing with a larger A/R for less backpressure over the previous OMSE spec turbo. It features lightweight thinwall non containment compressor and turbine housings. The compressor housing is made of magnesium while the exhaust housing is cast Inconel. The center section is not water cooled and has been cast from thinwall iron for lighter weight. The wheels spin on ceramic ball bearings for low friction and fast spooling. The exhaust housing is open single scroll and is fed from a 4-1 tubular header with a large water cooled TiAL wastegate. Antilag creates a lot of heat so the wastegate must be water cooled to live. Unfortunately, it's hard to see a lot of this trick stuff going on with all of the heat jacketing in place. The turbo weighs only 9 lbs due to all of the attention spent on weight reduction while your typical stock turbo for an Evo X for instance weighs around 22 lbs! In this picture you can also see the cylinder head external water passage for the cross flow cooling system.

The turbo used on the mountune GRC engine is a variation of the legendary Garrett TR30R Motorsports turbo. The TR30R uses bespoke mountune wheels optimized for use with high boot and a lot of inlet restriction due to the mandated 45mm restrictor. mountune also speced an exhaust housing with a larger A/R for less backpressure over the previous OMSE spec turbo. It features lightweight thinwall non containment compressor and turbine housings. The compressor housing is made of magnesium while the exhaust housing is cast Inconel. The center section is not water cooled and has been cast from thinwall iron for lighter weight. The wheels spin on ceramic ball bearings for low friction and fast spooling. The exhaust housing is open single scroll and is fed from a 4-1 tubular header with a large water cooled TiAL wastegate. Antilag creates a lot of heat so the wastegate must be water cooled to live. Unfortunately, it's hard to see a lot of this trick stuff going on with all of the heat jacketing in place. The turbo weighs only 9 lbs due to all of the attention spent on weight reduction while your typical stock turbo for an Evo X for instance weighs around 22 lbs! In this picture you can also see the cylinder head external water passage for the cross flow cooling system. The restrictor is carefully made with its contour optimized using CFD for maximum air flow. It securely bolts to the front of the turbo. The turbo sucks air from a shielded airbox in the passenger side nose that contains a large K&N air filter.

The restrictor is carefully made with its contour optimized using CFD for maximum air flow. It securely bolts to the front of the turbo. The turbo sucks air from a shielded airbox in the passenger side nose that contains a large K&N air filter. The Pectel SQ6 fires the NGK M14 racing plugs with the aid of Denso direct fire coils which are sourced from another OEM application. We think they are Honda CBR type coils. The coils have their own internal igniter so they can be fired directly by the ECU. Direct fire is the only way to go in super high boost applications like this. Under load the engine runs about 20 degrees BTDC.

The Pectel SQ6 fires the NGK M14 racing plugs with the aid of Denso direct fire coils which are sourced from another OEM application. We think they are Honda CBR type coils. The coils have their own internal igniter so they can be fired directly by the ECU. Direct fire is the only way to go in super high boost applications like this. Under load the engine runs about 20 degrees BTDC. The mountune intake manifold is pretty interesting. The intake plenum is fed by a tapered tube from the intercooler that feeds the plenum chamber via slots between the tube and the plenum. This was found to feed all 4 cylinders more evenly with the low and small volume plenum needed in the tight space between the head and the shock tower. The arrangement you see here on top of the plenum is the 5th throttle which controls air for the anti lag system. The valve in the 5th throttle allows air to bypass the throttle plates where it is mixed with injected fuel and burned to keep the turbo speed up while the throttle is closed. The ECU greatly retards timing while antilag is operating to both increase exhaust heat to drive the turbo and to keep the engine from making torque while the throttle is closed. The antilag is so effective that sometimes traction suffers due to the extra torque the system can create. Since traction control is not allowed in GRC, the anti lag system is very tunable for the conditions.

The mountune intake manifold is pretty interesting. The intake plenum is fed by a tapered tube from the intercooler that feeds the plenum chamber via slots between the tube and the plenum. This was found to feed all 4 cylinders more evenly with the low and small volume plenum needed in the tight space between the head and the shock tower. The arrangement you see here on top of the plenum is the 5th throttle which controls air for the anti lag system. The valve in the 5th throttle allows air to bypass the throttle plates where it is mixed with injected fuel and burned to keep the turbo speed up while the throttle is closed. The ECU greatly retards timing while antilag is operating to both increase exhaust heat to drive the turbo and to keep the engine from making torque while the throttle is closed. The antilag is so effective that sometimes traction suffers due to the extra torque the system can create. Since traction control is not allowed in GRC, the anti lag system is very tunable for the conditions. The mountune intake manifold has individual throttle plates for each cylinder for best throttle response. The intake also features two individually staged injectors per cylinder spraying Sunoco 260 GT Plus fuel for best throttle response and best anti lag control. The rules require that the throttle be manually controlled so throttle actuation is by acable.

The mountune intake manifold has individual throttle plates for each cylinder for best throttle response. The intake also features two individually staged injectors per cylinder spraying Sunoco 260 GT Plus fuel for best throttle response and best anti lag control. The rules require that the throttle be manually controlled so throttle actuation is by acable.