,

Above is another diagram showing the normal operation of the crankcase ventilation system with half of the system greyed out.

That pathway is used around 90% of the time you drive the car. A little blow-by is pushed into the crankcase, but the intake manifold sucks it up and the oil separator in the valve cover keeps most of the oil from escaping the engine. The manifold keeps a good vacuum on the crankcase during idle and partial throttle conditions which amount to most of your driving.

“Okay Ben, what happens when you’re at WOT then?”

I’m glad you asked.

That’s where the other half of the system comes into play. There are a couple things happening at WOT.

First, there is no real vacuum to speak of in the intake manifold or plenum. With the throttle fully open, the entire intake tract experiences atmospheric pressure and no longer produces any vacuum. This means there won’t be any vacuum applied to the crankcase and blow-by evacuation will be problematic.

Second, WOT produces the most blow-by because of the pressure in the cylinder and the lack of vacuum in the crankcase (remember the vacuum promotes ring seal and without good ring seal there is more blow-by).

This means there is a lot more blow-by to deal with at WOT and there’s no vacuum to suck the blow-by up. In the past, OEMs just vented the crankcase to atmosphere and called it a day. In these times of pollution consciousnesses, spouting air with oil and gasoline vapors into the atmosphere untreated is a big no-no. So in an effort to control those emissions Nissan routed the gasses back into the intake to take advantage of the slight vacuum present in the intake (very slight) and also route the pollutants back into the engine to be consumed and eventually treated by the catalytic converter.

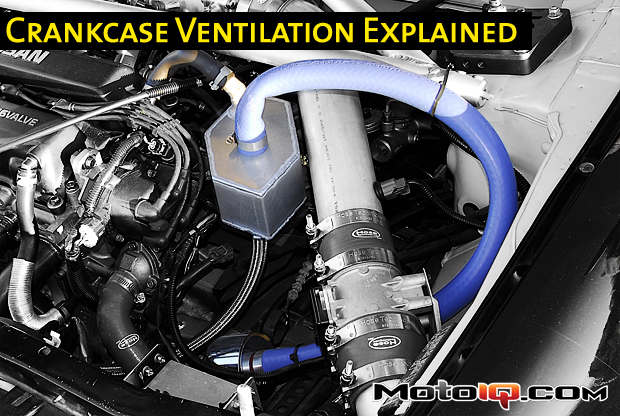

Because there’s not really any vacuum present, the blow-by gasses build up pressure and relatively slowly move up to the valve cover via both the left and right pathways. These pathways are also larger than the regular PCV hose because flow is important now that the vacuum is gone. Let’s follow the path of the blow-bay gasses at WOT.

They start out at the bottom just as before and this time they go up the timing chain section and the catch can section on the right. The pressure in the crankcase is now going to be about equal to that in the intake manifold, so not much of anything will flow through the PCV hose. The blow-by gasses will have to continue on through the valve cover where there is even more built-in oil separation labyrinth. Eventually the gasses leave the valve cover and meet up with the gasses that took the other route through the catch can. By now both routes have gone through an oil separator so the air is going to be relatively oil free.

Here is another diagram showing this part of the system with the regular section greyed out:

Those are the basics of the 1991-1999 SR20DE crankcase ventilation system.

Continue reading for a thorough explanation of the roller rocker (years 2000+) SR20DE and SR20VE (including N1 and 20V) crankcase ventilation system.