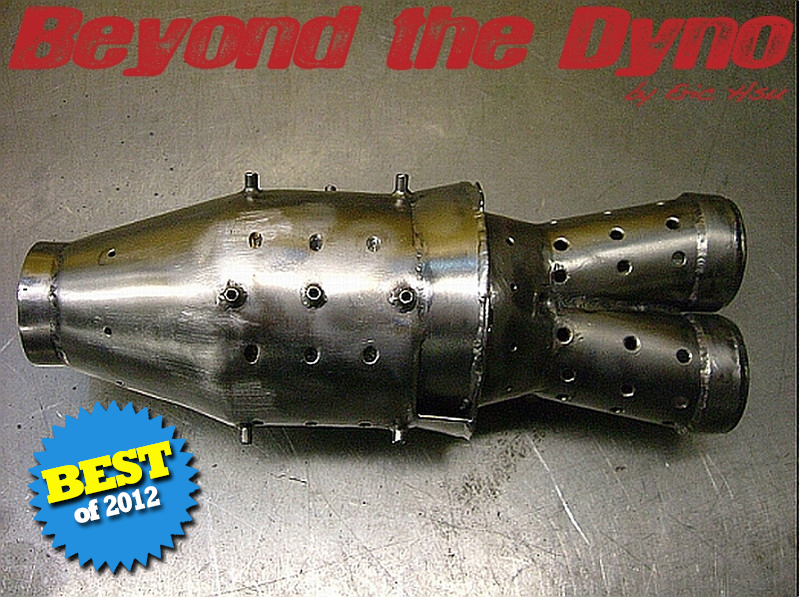

Here's a rocket (yes, he's got more than one) on the EJ20. The entire rocket is fabricated from Inconel for obvious reasons. Since it is essentially an external combustion chamber, it needs to withstand massive temperature peaks for short periods of time.

Here' s where the rocket sits in relation to the transmission and cylinder head. That electrical harness you see there was also relocated for obvious reasons.

Remember Ben's ex-Prodrive WRC fabricator buddy Elmo? I believe he handled most of the fabrication on the Spec C. The merging of two dissimilar diameter tubes with two different radii into a single 3″ tube here is something you would only find in a proper race car…oh wait, that's what Elmo does all day long. Check out the NTK Lambda sensor for the ultimate in wideband accuracy. The small Autosport connector is for the turbo speed sensor.

Here's the WRC spec IHI RX-6 turbocharger in place. This particular RX-6's bearing housing is designed for an angled or vertical installation for use even with wet sump oiling. Dry sumps are not allowed in WRC believe it or not. If you've ever seen a later Prodrive WRC Subaru, then you've seen the almost vertical mounting position of the turbo. The heat shield over the turbine housing is made of titanium. Notice the cable throttle body here. Somewhere later in this article, you'll notice that Ben brings the build into the 21st century with a fly by wire throttle.

Take a careful look at the turbo inlet tube and notice first of all that it is all bent in a single piece. I don't know if Elmo has a mandrel bender in his shed or what. Then notice as the tube enters the filter that the diameter slowly enlarges to the inlet of the filter. How did he do that? There's not even a nick on the tube from forming tools or anything. Ben chose a K&N cone filter because of the formed radius at the tube inlet and of course the proven flow of cotton gauze media.

The bespoke header tank is mounted with OE style vibration isolation mounts. Most factory aluminum components are typically isolated from the chassis because the vibration of a road car over time will cause brittle alloys like aluminum to crack. Since a high performance or race car sees even more vibration, aluminum component isolation should carry over to race car builds too right? Anyhow, this header tank is ultra clean. Notice that the top piece of the header tank has rounded edges all the way around. Nice piece!

1 comment

How much for one of the rocket systems for a 04 sti?