,

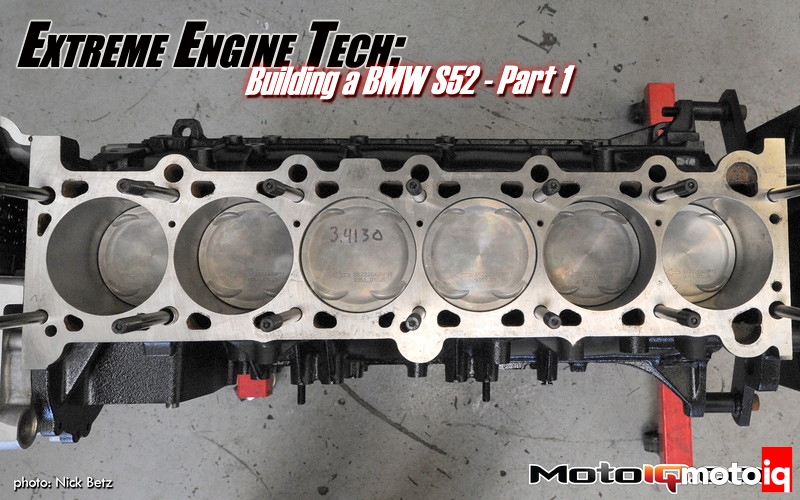

Mahle pistons are forged with a fully-machined crown. They come coated with a Grafal anti-friction coating on the skirts, which reduces drag, scuffing, friction and cylinder bore wear.

In order to keep everything spinning smoothly we called upon King Race Bearings. King Race Bearings XP series have many built in features that help with strength and overall bearing performance. Their pMax Black tri-metal structure is built to handle increased load capacity.

In order to keep everything spinning smoothly we called upon King Race Bearings. King Race Bearings XP series have many built in features that help with strength and overall bearing performance. Their pMax Black tri-metal structure is built to handle increased load capacity.  With their patented SecureBond micro-etch process that improves multi-layer adhesion and integrity you get a stronger copper intermediate layer and overlay. The unique 90* U-Groove shape helps with load distribution and durability at high RPM’s without any detriment to oil flow and lubrication.

With their patented SecureBond micro-etch process that improves multi-layer adhesion and integrity you get a stronger copper intermediate layer and overlay. The unique 90* U-Groove shape helps with load distribution and durability at high RPM’s without any detriment to oil flow and lubrication.  Since we want our rods to spin just as free as our crank we ordered up a set of King Race Bearing con-rod bearings to complement the main bearings.

Since we want our rods to spin just as free as our crank we ordered up a set of King Race Bearing con-rod bearings to complement the main bearings.  In order to hold everything together we’re giving our bottom end the ARP treatment with a set of ARP main studs. ARP is the go-to fastener for engine builds across all types of motorsports from drag racing to road racing to marine… You name it and ARP has their hands in it. All ARP studs and bolts are made in-house in the USA. We chose ARP studs over the stock torque to yield bolts because studs are easier on the block threads and the caps and girdle are held in better alignment. Studs also provide more accurate torque readings because they don't twist into the block when being tightened.

In order to hold everything together we’re giving our bottom end the ARP treatment with a set of ARP main studs. ARP is the go-to fastener for engine builds across all types of motorsports from drag racing to road racing to marine… You name it and ARP has their hands in it. All ARP studs and bolts are made in-house in the USA. We chose ARP studs over the stock torque to yield bolts because studs are easier on the block threads and the caps and girdle are held in better alignment. Studs also provide more accurate torque readings because they don't twist into the block when being tightened.  Along with ARP main studs we are going to be using ARP head studs to keep our new head married to the block. ARP studs are made of 8740 chromoly steel. 8740 has superior strength over a more common chromoly like 4130 because it has a higher carbon content and responds to heat treatment better. It also makes use of nickel as an alloying element which increases toughness. 8740 has a very high tensile strength of around 200,000 psi. The ARP studs also have several design features like rolled (superior to cut threads due to good grain formation in the thread root) asymmetrical J-form threads with more engagement area on the stressed side and a reduced center diameter to reduce stress risers. ARP studs also have high quality forged nuts and precision ground and hardened washers for accurate torque and positive retention.

Along with ARP main studs we are going to be using ARP head studs to keep our new head married to the block. ARP studs are made of 8740 chromoly steel. 8740 has superior strength over a more common chromoly like 4130 because it has a higher carbon content and responds to heat treatment better. It also makes use of nickel as an alloying element which increases toughness. 8740 has a very high tensile strength of around 200,000 psi. The ARP studs also have several design features like rolled (superior to cut threads due to good grain formation in the thread root) asymmetrical J-form threads with more engagement area on the stressed side and a reduced center diameter to reduce stress risers. ARP studs also have high quality forged nuts and precision ground and hardened washers for accurate torque and positive retention.

2 comments

Not sure when this was posted but thanks! I’ve had a lot of BMWs in the past but nothing later than an e30 and am now looking into a ’96 e36 328is. I’ve been searching for REAL information about a sensible but effective build to reach the M series performance levels and this is the first REAL build I’ve found that speaks my language (brought up on hot rods and muscle cars) My main question is how can you increase the stroke without shortening either the rods or piston pin height?? Or do the M3 pistons have a different pin placement than the m50/52? (I was trying to avoid using all the m50 etc, frankly you need a damn score card to keep track of it all.

One of the first questions I had after reviewing engine specs was if the M car crank will fit the IS block and cool – yes it will! Another was how much the cast iron blocks can be overbored another point! So now I can toss out all that fan boy (never actually built a motor but know it all) “info” and get back to a proper build, bore, stroke, pistons, cams and go. One question if you are still reading… actually I am going to add this up top. RE pistons 323 328 vs M3 seems to me you can’t increase the stroke without shortening something either the rod length or piston pin height.?

Thank y’all for this write up. Restoring my M3 (minus stuff that weighs too much) and my dad rebuilt my motor for Christmas from this post. Big time.