,

We couldn’t resist getting a new OEM oil pump either, which we ordered through Pure Performance during the build process. It was worth the extra expenditure.

We couldn’t resist getting a new OEM oil pump either, which we ordered through Pure Performance during the build process. It was worth the extra expenditure.  Here’s a really cool trick and something that shows why you want to go to a specialty shop when building a high performance engine. The guys at Pure Performance took the time to drill out the oil gear nut so it could be safety wired. This was something I didn’t ask for, mostly because I didn’t know about it. The oil nut on the M/S52 engine is notorious for backing itself off in track-driving situations. With the nut safety wired to the gear it’s no longer a worry.

Here’s a really cool trick and something that shows why you want to go to a specialty shop when building a high performance engine. The guys at Pure Performance took the time to drill out the oil gear nut so it could be safety wired. This was something I didn’t ask for, mostly because I didn’t know about it. The oil nut on the M/S52 engine is notorious for backing itself off in track-driving situations. With the nut safety wired to the gear it’s no longer a worry.  With the new timing chains and oil pump chain installed our freshly cleaned timing cover completes the look. Also, when sending out a block to get decked, make sure to send the timing cover as well since it will need to match the deck height of the block.

With the new timing chains and oil pump chain installed our freshly cleaned timing cover completes the look. Also, when sending out a block to get decked, make sure to send the timing cover as well since it will need to match the deck height of the block.  We then installed the new EMP-Stewart High-Performance Water Pump we got from Pelican Parts.

We then installed the new EMP-Stewart High-Performance Water Pump we got from Pelican Parts.  With the front cover and water pump installed it’s time to install the ARP head studs. Just like the main studs, make sure to hand tighten them to a snug fit and then torque to the manufacturer’s specs.

With the front cover and water pump installed it’s time to install the ARP head studs. Just like the main studs, make sure to hand tighten them to a snug fit and then torque to the manufacturer’s specs.  And the icing on the cake is our JE ProSeal cut-ring gasket. Just slide the gasket in place like you would any other gasket, install the cut-rings and enjoy!

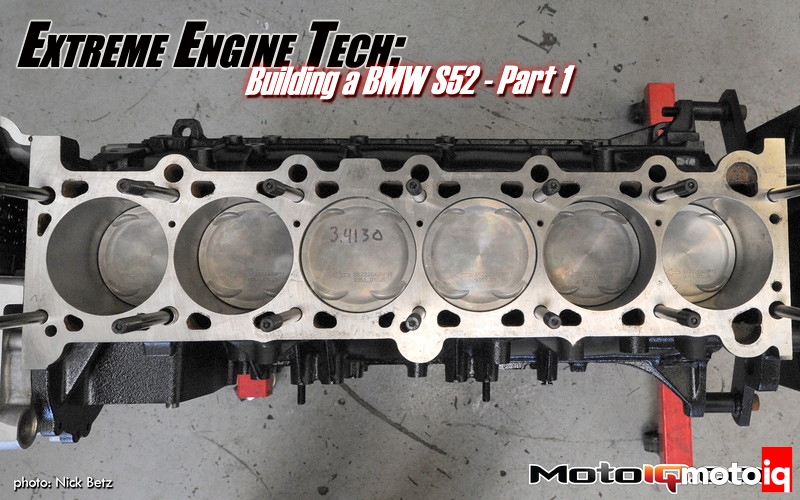

And the icing on the cake is our JE ProSeal cut-ring gasket. Just slide the gasket in place like you would any other gasket, install the cut-rings and enjoy! We now have 3.2 liters of high-compression engine ready to get a top end installed. Stay tuned for our next installment covering the head, valvetrain, cams and more.

Sources:

2 comments

Not sure when this was posted but thanks! I’ve had a lot of BMWs in the past but nothing later than an e30 and am now looking into a ’96 e36 328is. I’ve been searching for REAL information about a sensible but effective build to reach the M series performance levels and this is the first REAL build I’ve found that speaks my language (brought up on hot rods and muscle cars) My main question is how can you increase the stroke without shortening either the rods or piston pin height?? Or do the M3 pistons have a different pin placement than the m50/52? (I was trying to avoid using all the m50 etc, frankly you need a damn score card to keep track of it all.

One of the first questions I had after reviewing engine specs was if the M car crank will fit the IS block and cool – yes it will! Another was how much the cast iron blocks can be overbored another point! So now I can toss out all that fan boy (never actually built a motor but know it all) “info” and get back to a proper build, bore, stroke, pistons, cams and go. One question if you are still reading… actually I am going to add this up top. RE pistons 323 328 vs M3 seems to me you can’t increase the stroke without shortening something either the rod length or piston pin height.?

Thank y’all for this write up. Restoring my M3 (minus stuff that weighs too much) and my dad rebuilt my motor for Christmas from this post. Big time.