,

Once you’ve installed the main caps and tightened the ARP main stud bolts to a nice snug fit you’ll need to properly torque them to the required specifications.

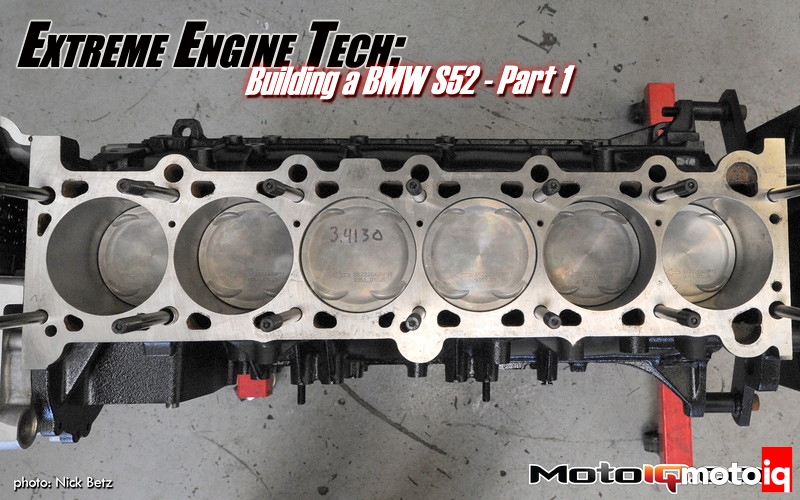

Once you’ve installed the main caps and tightened the ARP main stud bolts to a nice snug fit you’ll need to properly torque them to the required specifications.  Once the crank is secured and tightened you’ll need to assemble your rod and piston combo. Here you can see the bore size on the piston used to bore out the block. We highly recommend you send a piston out with your block to make sure the measurements are done correctly. Don’t just take the printed size as is, millimeters can make or break your build.

Once the crank is secured and tightened you’ll need to assemble your rod and piston combo. Here you can see the bore size on the piston used to bore out the block. We highly recommend you send a piston out with your block to make sure the measurements are done correctly. Don’t just take the printed size as is, millimeters can make or break your build.  With your rods and pistons assembled it’s time to install the belly of the beast. First thing you will want to do is check your ring clearance. You’ll want to install and square up all the top rings and check the gap to make sure everything is within tolerance.

With your rods and pistons assembled it’s time to install the belly of the beast. First thing you will want to do is check your ring clearance. You’ll want to install and square up all the top rings and check the gap to make sure everything is within tolerance.  Once tolerances are checked and you are positive the ring gap is good install the rings onto the piston.

Once tolerances are checked and you are positive the ring gap is good install the rings onto the piston.  Rods assembled to piston, check. Rings on piston, check. ARP ring compressor, check.

Rods assembled to piston, check. Rings on piston, check. ARP ring compressor, check.  When installing pistons into the block you might want to look away. Yes we’re dealing with metal that isn’t going to get hurt by the rubber end of a mallet but watching (or doing it yourself) the top of your brand-new pistons getting vigorously pounded on will always makes you cringe. Also, make sure the crank journal is at the bottom of the stroke – you don’t want the connecting rod to come down and score the journal.

When installing pistons into the block you might want to look away. Yes we’re dealing with metal that isn’t going to get hurt by the rubber end of a mallet but watching (or doing it yourself) the top of your brand-new pistons getting vigorously pounded on will always makes you cringe. Also, make sure the crank journal is at the bottom of the stroke – you don’t want the connecting rod to come down and score the journal.

2 comments

Not sure when this was posted but thanks! I’ve had a lot of BMWs in the past but nothing later than an e30 and am now looking into a ’96 e36 328is. I’ve been searching for REAL information about a sensible but effective build to reach the M series performance levels and this is the first REAL build I’ve found that speaks my language (brought up on hot rods and muscle cars) My main question is how can you increase the stroke without shortening either the rods or piston pin height?? Or do the M3 pistons have a different pin placement than the m50/52? (I was trying to avoid using all the m50 etc, frankly you need a damn score card to keep track of it all.

One of the first questions I had after reviewing engine specs was if the M car crank will fit the IS block and cool – yes it will! Another was how much the cast iron blocks can be overbored another point! So now I can toss out all that fan boy (never actually built a motor but know it all) “info” and get back to a proper build, bore, stroke, pistons, cams and go. One question if you are still reading… actually I am going to add this up top. RE pistons 323 328 vs M3 seems to me you can’t increase the stroke without shortening something either the rod length or piston pin height.?

Thank y’all for this write up. Restoring my M3 (minus stuff that weighs too much) and my dad rebuilt my motor for Christmas from this post. Big time.