,

We used JE's piston rings which we have always had very good luck with in all sorts of competition use. The compression rings are thin at 1.1mm and 1.2mm and low tension in design for less friction. Rings are the largest source of mechanical friction in an engine.

The top ring is 1.1mm and is plasma chrome coated for low friction, long life and heat resistance.

The 1.2mm thick ductile iron second ring has a hooked face Naiper profile. Naiper rings break in quickly and give better oil control at high rpm and are really low friction.

Narrow profile and low tension describes JE's oil rings. The scrapers and waffled separators are shown here. There are two scrapers on either side of the the separator. The separator gives space for the oil to drain to the interior of the piston via holes in the oil ring groove. This helps keep the piston pin lubricated. We did not want to have an oiling hole in the rod or pin oiler holes in the piston pin boss. This will help keep the small end of the rod and pin boss of the piston strong for the high compressive loads a high boost turbo engine will make.

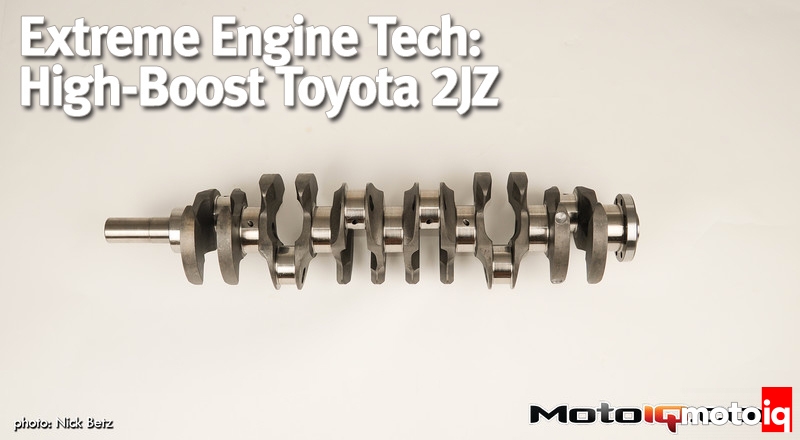

We will be looking at the rest of the engine real soon, right now the core block we were planning to use had scored cylinder walls that would not clean up with a 1mm over bore so we are looking for a new core. With the success that mega powered 2JZ's have been having in Formula D, it seems like everyone wants one now and cores are hard to find.

We blame Daigo Saito…

Sources

Brian Crower

JE Pistons

3 comments

Hi dear

I need thick piston pins for 2JZ GTE can you provide me 12 pices of pins and how much will cost with fast delivery to United Arab Emirates

We suggest you contact your piston manufacture.

Always wishing to see the next phase of this one when I click on MotoIQ

Also. What happened to Dave Coleman