,

|

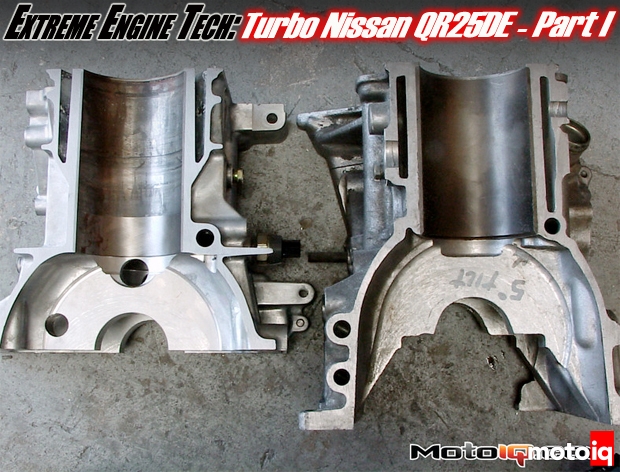

| The balance shaft assembly is found in the bottom of the oil pan submerged in oil. It is the weakest link in the chain when the QR25DE is modified. On 2007 and later QR25DE’s, the balance shafts were deleted. |

One of the first issues that JWT addressed in our motor is the problems of seizing balance shafts. Balance shafts work to cancel out a 4 cylinder engines inherent up and down shaking moments and spin at twice the crank rpm. This means that at 6100 rpm the shafts are zinging at 12200 rpm, it’s a small wonder that they have problems with seizing in their housings. If you raise the rev limit much past the embarrassingly low stock limit of 6100 rpm, the balance shafts seize in their bores creating a chain of events that destroys the engine. On the QR, the balance shafts are the first failure point.

JWT also felt that the balance shafts helped to contribute to some of the QR25’s other problems, excess oil consumption and bearing failure. The balance shafts are submerged in the oil pan and when spinning at 12,000+ rpm they churn the oil to a frothy mixture of oil and air. This aerated oil, if ingested by the oil pump can cause bearing failures. The churning balance shafts can also fling oil around inside the block contributing to excess windage and increased oil consumption.

|

| JWT balance shaft eliminator kit removes the problem and also features a pan baffle and windage tray to help control oiling better as well. |

JWT removed the balance shaft assembly to address these problems. On the QR the balance shafts are chain driven from the crank and contained in a separate assembly bolted to the main caps. JWT used their balance shaft removal kit which has spacers for the main cap bolts, plugs for the oil passages and instructions on how to remove the drive chain for the shafts. The kit also comes with a windage tray to help speed the return of oil off the crank and free up some power caused by the crank spinning in a cloud of oil. The kit also includes a pan baffle to help ensure that the oil pump can still be submerged in oil even under hard cornering. The total oil capacity is increased by a quart as the balance shaft assembly is submerged in oil and its removal makes room for more oil. Eliminating the balance shafts and the oil demand from their journal bearings increases oil pressure and makes more oil available for the main and rod bearings. The balance shaft removal kit doesn’t seem to cause more perceptible vibration and frees up an additional 8-10 wheel hp.

|

| When compared to the beefy SR20 crank, it is easy to see that the QR totally lacks any overlap of the rod and main bearing journals. Lack of overlap makes for a much weaker crank. |

Nissan probably deemed the balance shafts necessary because they used a lightweight crankshaft with only 4 counterweights probably in an effort to reduce reciprocating weight and windage losses. Unfortunately the crankshaft is weak with no journal overlap and not enough bearing area to support higher loads and revs. The crankshaft has proven to be failure prone in the RTR World Challenge racer. JWT addressed this problem by using a 2006 and later crankshaft. The 2007+ QR crank is from the later model B16 Spec-V QR25DE variant. This engine has a 7000 rpm redline. This is how the QR25DE should have been from the launch. The late model engine has a fully counterweighted crankshaft with generous fillets for additional durability. JWT Deburred and balanced the late model crank , WPC ( read about how WPC works here) treating it to reduce friction and help improve fatigue strength.

|

| The 2007 crank on the bottom features full counterweights and beefier construction. Note the additional material in the cheek area of the throws. JWT balanced, mircopolished and WPC treated the crank for strength. |

52 comments

I have questions about turbo charging my QR25DE engine.

Hahaha, don’t!

Why not? that’s why they made this article for right?

Is it too expensive? unreliable even with the right parts?

It is a pretty weak engine. It responds well to turbocharging making good power but its hard to make it reliable. The engine has a weak crank, small bearing area, long stroke and poor rod ratio combined with poor water jacketing and poor head sealing make thing problematic. For easy street use and occasional drag racing maybe on low boost but no track days, etc.

I was thinking about starting with a 07+ block and replace the internals with forged parts. Doing something very similar like what you guys did with the QR25DE and probably push it close to 500 but using E85. I love my Nissan’s but I want professional advice before I start spending any more money.

It won’t last long at that power level.

Would sleeving the block help?

no. the main issue is not enough bearing area.

Would it last a while just keeping it around 300+

yes at that power level.

Thank you Mike, I appreciate all the advice.

Also the build I want to start is for street use only not track. Daily driver and some drag racing once in a while.

can i use parts from sr20 to qr20 engine

The crank comes close but needs machine work.

can i win something with the crank only

The SR20 crank has a shorter stroke, is much stronger and fully counterweighted.

i have an sr20 engine and i am asking if i can do something to my qr20 xtrail.can l use also the rod and then look for the right pistons?

do i change the compression with this things

So… I have a 2018 Rogue.. Yes, Rogue, that I wanted to explore with performance upgrades. Long have I wanted to have a 500hp+ suv lol don’t judge me :p

So, I thought about turbocharging it. Came across this article. It made me quite sad tbh 😂 I won’t be tracking it, or even drag racing it. I just want a sprinkle of power to play with while driving.

Thoughts?

Runaway and buy a car better suited for performance.

I lol’d so hard at this comment.

So you selling the motoIQ specV?

That car never got done due to engine development issues.

Mike, what if I wanted to do a high compression build instead of turbo? would that application be better?

This engine is a poor higher performance engine. I don’t really recommend trying to build one.

I have a 2013 Altima with the qr25de and my goal for HP is 250HP. it’s completely stock at the moment. Could you give me some pointers as far as what mods to start with and where to go from there? Thanks.

Possibly, a header, Intake, JWT cams, and a balance shaft delete kit. Then find someone that can tune it. I probably would not modify the engine beyond this.

what about it’s brother, the QR20, which has 80.3mm stroke?

It is a weak crank.

I really like my Altima coupe I just wish it came turbocharged from factory. It would have sold a lot better and it would stututu.

So I have been looking at the pre-made “kits” for qr25de engines but they are all around $4900. So instead my question is, would I be able to make a t3/t4 universal turbo kit run safely on my qr25de? I am not looking to make anymore power than around 230-250hp I really do not care about the numbers as long as I can safely get the car to run a t3/t4 turbo. I want to pursue a career in which I work on cars so this wouldn’t be a situation where all I want is power, it would more be a test to see if I am be able to do it… I’ve already changed the stereo, wheels, brakes, exhaust and intake system with no help besides my phone and my tools that I borrow from my very nice neighbors. I don’t have access to a professional garage but I do have a lot of free time due to the pandemic.

Cheap, safe, turbo kit don’t go together very well!

Even if I don’t end up turbo charging my Altima coupe I’ll be installing new headers, new cams and a tune. I’ll probably call it a day after that but I still wish from factory the Altima coupe was turbo charged. It definitely has the looks just not the love from Nissan.

Hey y’all, I’m checking out a 2003 sentra SE-R Spec V through a private seller. I’m going to be meeting the owner to check it out, and then I have an appointment at a reliable mechanic shop for a pre-purchase inspection.

I’ve been looking up the QR25DE and all of it’s faults, I don’t plan on boosting the engine, I just want a fun car with a 6-speed to row through gears during road trips. I don’t need a car to commute, so it’s a hobby vehicle. Seller says they have complete service history from Nissan starting from 2006, and that it has a Nissan factory remanufactured engine with only 36,000 km that was installed by Nissan. The body has a total of 275 km.

My question is, what red flags should I be looking for?

I am also looking for:

Oil leaks from under the cylinder head cover

Idle problems and/or jerking caused by stretched timing chain

Random misfires

High oil consumption (this may take time to ascertain)

I know it’s not a race car and I know it won’t make 175 hp at the wheels.

any advice would be greatly appreciated.

I would probably take a pass on this unless it’s really cheap or you just love B15’s.

So my 2003 se-r qr25de with 157,000 blew a piston today from just driving around. i am thinking of buying another qr25de what should i upgrade on the engine to prevent another piston mishap again? i just want it to be more reliable than the last one. the only issue i had was it burned a lot of oil and required 1 qt about every 2 weeks.

Hello,

I have a salvage title 2012 rogue s fwd I use for off road shinanigins, can I modify the engine?

I have an x-trail 2004 qr25de that has spit out the thrust bearing damaged the block and crank, $1000 to repair it has 100,000 k’s everything is good apart from crank, block and bearings. I have another engine it is from a 2009 Nissan Presage, it is a good runner with 325000 k’s I think it is a gen2 engine so I would like to use the block and crank, does this sound reasonable?

Mr Kojima

Has anyone done a 92mm sleeved post 08′ qr25de all motor to compete with 102mm stroked 2.6L K series hondas? At least the Nissan has a factory 100mm full counter stroke crank post 08 from what I hear. Trav using JW know how was playing with SR20DE cranks in the QR25DE back in 2004 which would make excellent SR20DE replacement motors with more displacement no need for sleeving an SR20DE and then stroking it.

Finally is a turbo QR25DE with the right internals as heavy as an all motor VQ v6?

There is no way a QR can even come close to competing with a K motor. This motor was never any good and its not worth sinking money into it.

Mr Kojima, Travis or anyone that can chime in with experience

Can the SR20DE and SR20VET bottom end take the QR25DE head using SR chain and sprockets?

As I have access to plenty of SR bottom ends for beer and the QR25DE heads are plentiful.

Would allow me to run JWT cams, springs, retainers and the alloy chain guides instead of plastic along

with all the other SR bottom end after market options that are becoming surplus.

The aim is 260hp 9000rpm as I like the QR25DE heads more than the SR for price and design is

very simple with good backing from JWT.

Its for an RR 94 wide body March Impul using Volvo 360 I beam setup father and son project

That’s a cool little car! I would not bother with a lashup like that and it’s not going to make that sort of power. I would get a Honda K motor or at least an SR20VE in there.

We are thinking of calling the project ImpulSR and for oval track racing we have fitted KA heads to L series, Mazda B5 soch and E15ET heads to pushrod A series bottoms and even worked out how to run a FIA L series SOCH head onto the SR bottom end for kicks. Just looking to be different BUT we hear your avoid the headaches logic :)!!!. I can easily modify the QR top chain cover with CNC to bolt onto the SR bottom chain cover, water jackets, head bolt and oil feed/drain all no issues.

Alternatively also considering the SR20 crank into the QR25DE as we have a good crank machinist nearby and has looked at fitting 4g63 148mm rods to the 86mm SR crankshaft keeping the qr25de pistons.

Then we are looking a JWT cams, retainers with a little flow work and 48mm itbs, motec and

custom headers 2140cc and 1inch sectioned grouting an inch below the deck height.

Otherwise last resort is a VE head from Japan but getting very pricey specially if something goes wrong with the upper bits. Honda is definitely much easier!!!! just wanted to keep it all Nissan.

Might still do the FIA L series head SR bottom combo just looking at all Nissan options etc.

We might even do the Honda engine but on a gen 1 civic as a neighbor has halve a dozen of them waiting for some love, he even has a Z600 but best left original.

Are you in Ireland by any chance, my Irish friends tell me of an oval track series using these cars. An FIA head is way behind the times, I think the easiest cheapest option will be the VE head, The engines are not that expensive, in our country, they are cheaper used than KA’s. Kelford has a lot of cam options for these.

Thanks not in Ireland and didnt know that they oval track them there!

We have oval tracked open wheelers with many japanese engines and

the most used was the A12 with E15et heads and larger class the L16

and L18 with sleeving w/ Ka24de head conversions not much involved.

Most of the competitors are boiler makers, industrial engineers and

all walks of mechanical eclectic freaks that do it for fun and challenges.

The FIA head is definitely way behind the times!!! yet lining it up with

a qr25de bottom end is tempting as we are searching for low weight

and big capacity combo was making 248hp with meth and 15:1 in 2.1L.

The extra 400cc is always tempting for an all motor combo with 50mm

50mm OERs for increased tinnitus! yet like you say VE head is the pick.

i know this is an old thread just placing my 2 cents since I actually built a QR25de from the ground up

i started to build a QR25DE YEARS ago! I just recently finished it.. (turbo)

it dyno 465whp / 353TQ at 7200 (15PSI)and the main problem I am having is…

GRIP!!!

the dam thing will overpower the tires (215 thick) on 1, 2, and 3rd also the front floats once you are at full power..

anyhow it was bittersweet because I can’t keep that power down and yes I am one of the few who sunk A LOT of money into developing the engine

I reinforced as much as I could while following this guide specifically..

sleeved block, k1 rods, reinforced crank, cp pistons.. Clevite bearings

JWT cams, titanium springs..

i basically tried to overbuild the engine..

some of the very good points this engine has are:

torque

it breaths extremely well

my builder was VERY surprised by the power level and he mentioned that he left it at 460 because that was the power goal I wanted, but the build could easily do close to 520

(of course, the fueling had to be heavily modded for 93oct)

Honestly, you are all better off buying a VQ conversion kit from 2j Racing and dropping a lightly used or built VQ in the Sentra.. apparently, you can use the 6speed from the Sentra with some modifications, also the transmissions are pretty decent, some people have reported up to 600whp on stock trans

daily driven I get on it sometimes when traffic allows, if you don’t get on Boost, it just drives like a normal car, and Boost kicks in at 4500 thru 7200 which is pretty dam short

if I had known better, I would have built an LS and dropped it into a d21 there are WAY more parts to make power with a junk yard-boosted LS engine.

That is so interesting!

So with a QR25E later edition, what is the recommend items and steps to get the engine to the 210 HP listed as ideal in the article? and where can one get the parts needed?

I am looking to improve the performance of the engine but not the racing or extreme HP levels others mentioned. The article is great at detailing some of the work but does not provide help in going down the same route.

Don’t do it,

The reason i believe Mike is saying to not do it is because of MONEY!

you would need a tune when my QR25 was N/A (considering i had made a lot of internal mods at this point)

you could stabilize the heads with a semi-close deck insert found at 2j, JWT S1 cams, and springs..

delete the counterbalance, ARP EVERYTHING up and down, fix the secondary butterfly screws or get the plenum intake delete kit, also make sure is all balanced..(engine)

and MAYBE MAYBE with a tune, you would be at 220whp at that point

a yes I forgot the injectors.. bigger .. much bigger like 440cc

side note, the builder will ask you before tuning, what size and delay/time on the injectors, apparently injectors have a slur of information that the builder needs to tune the timing

on the flip side, qr25 are very cheap, you can get a fairly new one for about 1K

engine lasted 2 days at 460whp turbo, the crankshaft pulley came apart, i am now close to 5k in repairs.. the 2007 from a nissan sentra 1.8 is fully counter balanced as in the article and it fits.. i had Cranks vibrational issues TWICE! the first time the ATI dampener literally came off and flew off on me on the freeway, the second time it was much worse becuase i was at boost and the chain comletely came off and destroyed the valves, i will rebuilt one more time and if necessary.. WELD THE DAM DAMPENER to the crank, consider thatwe had a machine shop do the balancing of the engine so.. pistons and crankall together.. FML also the red line was right at 7500 we are going to drop it to 7250 build all the oil system with billet parts from 2j and SEAL the ATI dampener to the crankl shaft, so next time if it blows up i want it to blow a piston on the side, not just a dumbass dampener coame lose and fucked evetythign up situation

You are a fighter Anuar, keep going at it. I love the dedication to the QR!

I know this is an old post but I would like to ask a few questions, even if no-one replies. Why is Mike being so critical to the qr25de? I have seen a qr25de in an x-trail make 500 hp with just rods, block guard, a balance shaft delete, Haltech and turbo with no intercooler (it didn’t last long as the head gasket failed). If I was to do rods, pistons, balance shaft delete, block guard, better head gasket and turbo with an intercooler, would 350+ be achievable? If so how much hp would I be able to make at the max?

Thank you

Because it is really a horrible engine. I would not waste money on it.