,

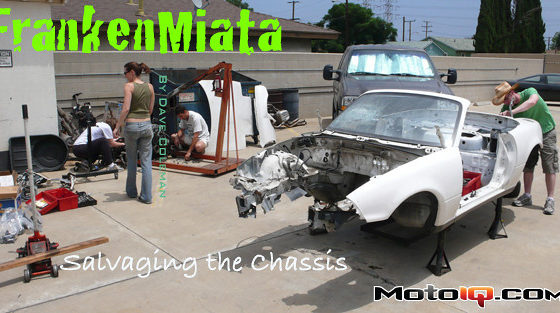

Arsefreezapalooza was right! It was so cold for our first outing, we had to drain the water from our radiator overnight to keep it from freezing and cracking the block.

We took the Frankenmiata to its first event, the 2008 Thunderhill Arsefreezapalooza, with a safe-and-sane 144 hp. Success at our main goal (not getting crushed) was helped by the science fair project board we made, showing the humble roots of our horrible car. By the time we reached the track, we were so proud of our contraption, we were convinced anybody who hadn’t heard the backstory would assume it was over budget and worthy of a crushing. We probably had nothing to worry about…

Considering the complexity of our creation, relatively little went wrong. There was that little knocking noise (which turned out to be a little issue with our used rod bearings) and a broken hood hinge. The hood hinge, unfortunately, had been repurposed and was being used as a support bracket for the massive downpipe. When it broke, it was only a matter of time before the downpipe snapped off, dumping hot turbo fury right on the windshield.

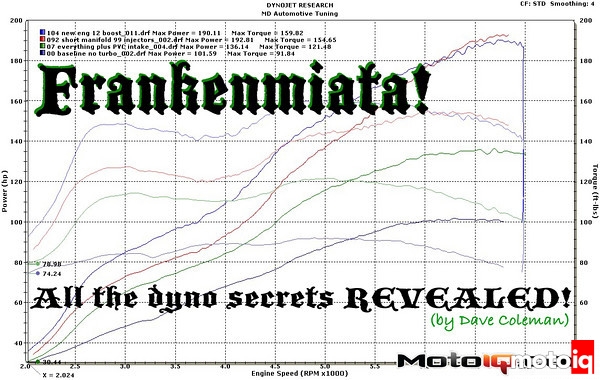

A few more reasonably drama-free races and, buoyed by our lack of failure, we returned to dyno in search of more power. In spite of the fear in our hearts when the boost crept to 7 psi on our first test, our first thought was more boost. We don’t run a boost gauge in the car, partially because we thought it would look too expensive, and partially because it would be an unnecessary distraction. We occasionally use a boost gauge on the dyno, though, and it looked like we were only getting 3.5 or 4 psi.

There’s a reason I’m being vauge here, and the reason is ignorance. It helps to remember that most boost gauges swing from a pretty deep vacuum up to 30 psi, making it hard to accurately read such a small boost reading. The cheap gauges we tend to use can often be off by 1 psi when they’re just sitting there. Hell, the needle itself is 2 psi wide on our crappiest gauge. We really never had any idea how much boost we were running, other than it wasn’t very much.

Anyway, the theory behind out boost gauge was that maybe if we could raise the boost just a hair, like from 4ish to 5ish psi, we could stay under the firey death threshold while picking up a nice, broad gain across the whole powerband. After all, ours was probably the lowest boost Miata in the history of turbo Miatas. There had to be some headroom.

We made a free boost controller by grabbing a chunk of 1/4″ aluminum rod, cutting down the OD until it could be crammed into a vacuum hose, and then driling a tiny hole through it. We made several of these little pills, each with a different size hole. Then we put a tee fitting in the wastegate signal line, and ran the third leg of that tee to nothing at all. The boost leaking out that bleed hose reduced the signal to the wastegate, and by jamming different pills in the hose, we could adjust how much boost bled out, and how much still got to the wastegate. Bigger hole = more boost lost out the bleed, and more boost made by the turbo before enough pressure reaches the wastegate diaphragm.

Dyno Chart #6: It worked!

Or did it? After a little trial and error, we had this happy little across-the-board gain, but the engine was pinging like crazy. We tried retarding timing and lowering boost until the pinging disappeared, but by then we were right back where we stared. Somehow, by complete dumb-ass luck, we had been running on the ragged edge the whole time. We ended this dyno session exactly where we began.

We couldn’t be sure why our car could only handle 4ish psi of boost while every other Miata with an equally crude fuel system could easily manage 7 psi, but we had a theory. Oil has a really low octane rating, and we were burning half a quart with every tank of gas. Maybe burning all that oil was lowering our knock threshold.