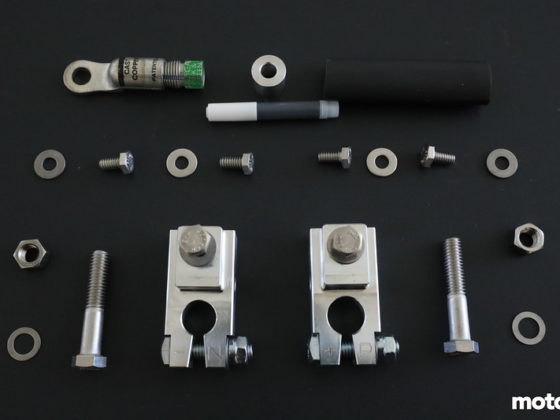

This is the base of the valve stack and bottom nut, The center spindle of the valve assembly screws into it.

This is the one way check valve that makes sure that the fluid flows through the valves only in the compression direction. The valve was made with a large surface area and is sprung by the two belleville springs behind it. By making the surface area of the valve large it doesnt have to travel far to react and the belleville springs can produce a consistent force with a small area of travel. This is a trick to speed the valve response time. A large metering area for adequate fluid flow and short travel reacts faster than a smaller valve sprung with a coil spring that has to travel farther to flow the same amount!

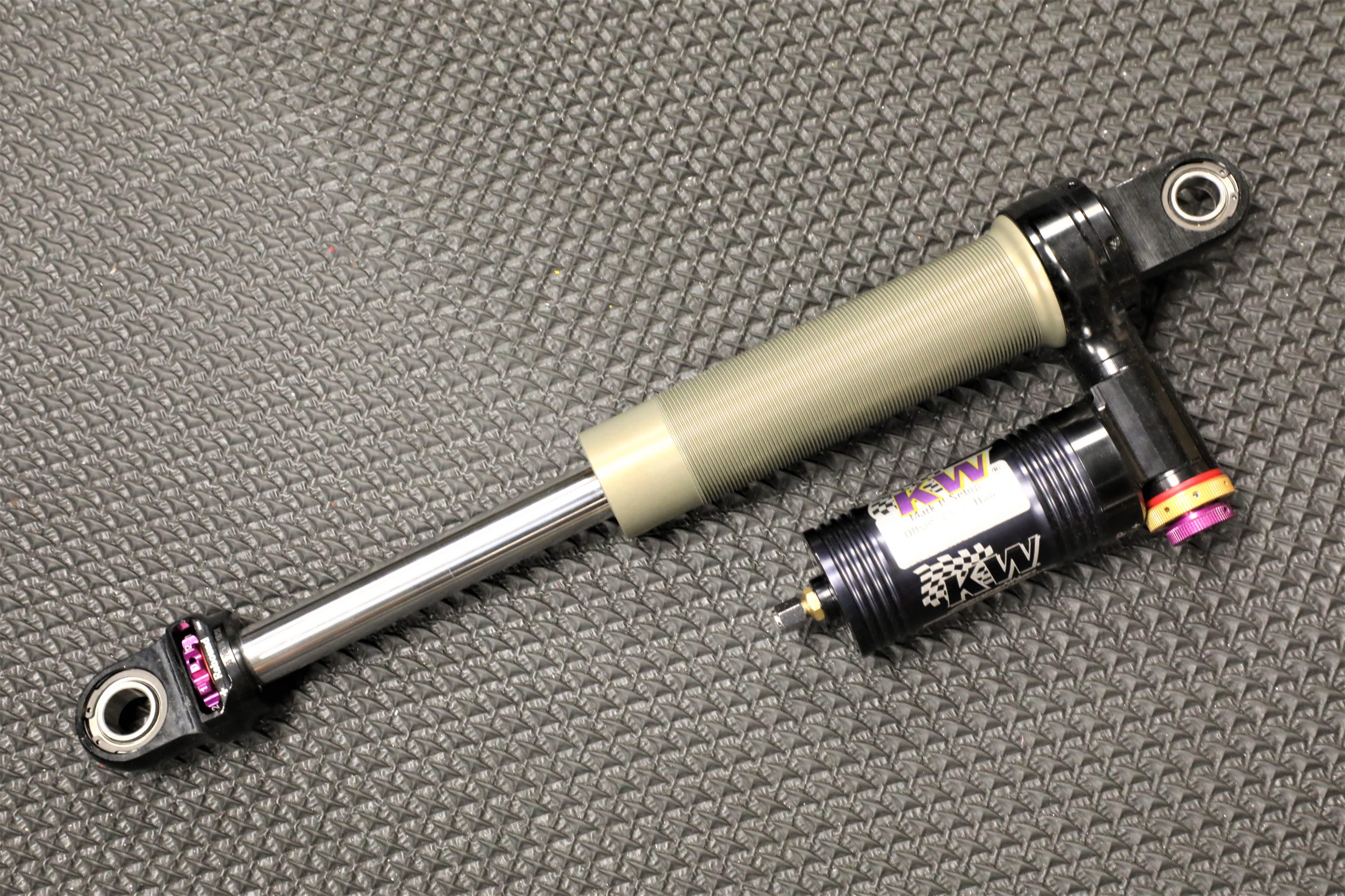

This is the low speed circuit and the adjusting knobs. The low speed damping is controlled by the brass needle valve that screws into the center spindle. The low speed flow is adjusted by screwing the needle higher or lower via the purple knob, in the spindle body which covers and uncovers more or less of the orifices controlling the low speed damping fluid flow. The low speed damping is calibrated by using different needle sizes and geometry and center spindles with different seat and orifice sizes. The needle is machined out of brass because it can be more precisely machined than other metals and is more thermally dimensionally stable to help keep the damping constant across a wide range of operating temperatures.

This is the high speed compression damping circuit that is adjustable by turning the gold knob. The gold knob clamps to the outside of the fat end of the center spindle. The knob screws the center spindle in and out adding or reducing preload the the stack of belleville springs. These springs load the high speed valve which is the silver colored thing sitting on top of the brass valve body. Again brass is used for its manageability and thermal dimensional stability. The high speed circuit is a blow off valve that opens when a high speed impulse hits the suspension like hitting an FIA Kerb or some kind of bump. Sudden transitions like turn in can also blow open the high speed circuit.

Like the check valve, using larger surface area valves with short travel belleville springs is a trick to speed up valve response time over using coil springs and smaller valves. The high speed circuit is tuned by using different valve bodies, different valve diameters and different rates and numbers of belleville spring washers.

On the rebound side there are two styles of pistons and valves that can be used. The above piston and rebound valve is used when higher hysteresis is wanted in the system. It uses a coil sprung valve. In some cases like a course that has broken pavement and small sharp high frequency bumps, especially at lower speeds, having some hysteresis can possibly help find more grip. We have used this with success in Formula Drift and Pikes Peak.

8 comments

I’m going to have to do some napkin drawings after I’ve had enough coffee; I’m not saying anything against them, but some of the ways KW do things are very different than I’m used to.

The low speed is much like any other shock, via a needle valve. The high-speed short travel fast response valves are certainly different than your traditional deflecting disc, poppet or spool valves.

The execution of the needle valve is a lot different though even if it works similarly.

The high speed blowoff stuff reminds me a bit of the Penske regressive valve in terms of how the closing shim moves (not the port shape interaction, just the shim moving straight with a spring preload vs deflecting); I’d expect kind of a sharper divide between high speed adjustments and low speed on that vs the conventional style of high speed adjustment… like the shim stack varying preload is going to open more and more with flow while KW’s should, once the pressure hits whatever value, open a lot more area all at once. KW’s method seems like it’d be more sensitive to manufacturing tolerances on the bellville setup but obviously they have it working.

This stuff really is fascinating to me – I mean it’s all “a pressure sensitive valve that changes its open area” but the number of ways to do that is huge.

Yeah it’s more of a reverse needle.

Does KW have a prevalved set of shocks that would work on my Subaru Legacy that I could order for our local timed rally cross events in Sonoma Calif? My Legacy has 1032 whp and 888 ft lbs of torque and currently weighs 2550 lbs with me in the seat.

KW ERX shocks are from their Motorsports line and are made to order. They could certainly build you a set of shocks. Man, tell us more about your car, that seems worthy of a MotoIQ feature!

Any interest in building a mono shock for flat track motorcycle racing? 92 RWHP, 750 cc, 325 pounds, spec tire. Currently using Penske.

Ohlins might have an application using through-shaft solid piston technology.