There has been a resurgence of interest in 90’s Japanese cars as of late and with that a surge in new parts development with specific popular models. In our case, it is the Nissan Z32 300ZXTT that was Sport Compact Car’s famous project car back in the ’90s. The car has been sitting in indoor storage for the last 20 years and it sprung a leak in one of the freeze plugs which means we have to pull the motor. We thought that since the engine had to come out, it would be a good time to modernize the VG30DETT engine and address some of its weaknesses that have been discovered over the years, one of which is a weak, compared to modern engines, bottom end.

The VG30DETT block is a cast iron part which gives it great stiffness. When we first built this motor, anything making 550 wheel hp was considered to be really good and the VG block could easily accommodate this power level. With improved exhaust manifolds and better turbos, VG’s started to be capable of much more power and soon people were making over 800whp. About this time the structural limits of the block started to be reached. On the VG the area where signs of distress occur is in the area of the main caps.

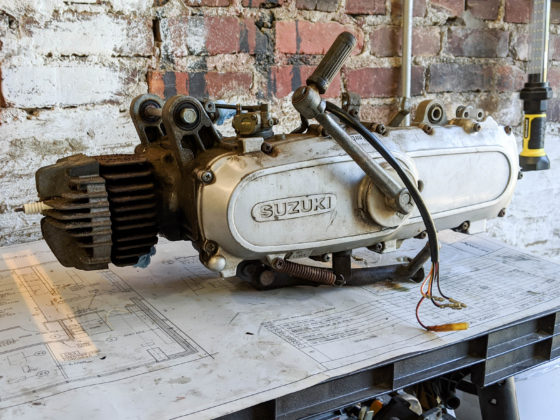

When building customers’ VG engines, we started to notice that the main caps were starting to get fretted and the registers of the main caps were all beat up. The main bearings would show uneven wear and signs of distress as well. These are indications that the main caps and even the webbing of the block were starting to flex from the strain. The fretting and bearing damage looked like the picture above. This isn’t a VG engine but it was a good example of what we were seeing. The damage we would see was often worse than this!

Fretting also shows between the cap and the bearing shell. It is caused by the metal surfaces rubbing against each other under a high clamp load. Anytime you see these sorts of patterns when you disassemble an engine, it is a sure sign of trouble where you are approaching the design limits of the block! We never thought we would see this in an iron VG block but our last customer VG exhibited extreme fretting even though the car only produced about 650 whp. We think it’s because it was mostly run on crappy 91-octane California fuel and the fretting load was caused by transient detonation.

We decided to reinforce our block with some billet main caps from EPR/Engineered Performance. The cast iron stock main caps are replaced with 1045 billet steel parts. 1045 steel is ductile and forgiving in this application and is many times stronger than cast iron.

9 comments

http://epracing.net/ too; actually came across them from watching some GTP oriented groups, seems like they’re working on doing a lot of stuff to keep the old cars running, which is awesome.

It’s funny to think of iron blocks as reaching their limits after all the stereotypes of the 2JZ and stuff but it’s not new; Electramotive actually had redesigned aluminum blocks cast to fix reliability issues back in the day.

They have built 2 of my VG engines and working on #3. Very happy with my engines. They do next level work.

Very nice information. These new parts look promising!!

Love this article. Thanks for keeping your 300ZX project going. The Z32 community thanks you.

Great to see more articles related to the Z32 platform. Keep it up! Also, it would be even better to create a series of videos on the YouTube channel. Been loving the content!

Videos coming!

I prefer the BDE billet girdle design over EP racings. Sponsorships are a “thing” but it’s much more stout in my opinion as it’s one piece with less points of failure, and has waaaay more tie in to the block. I am not sure EPR has the FEA work done on this either, which is problematic.

Check it out:

https://conceptzperformance.com/bde-billet-bedplate-girdle-assembly-w-oil-pan-upgrade-kit-nissan-300zx-90-96-z32-vg30dett-bde-bb001_p_64319.php

The EP Racing one was more affordable for me and my power goals are in the 3-digit range so I decided good enough. If I was going to G30 turbos instead of G25 I would have bought the BDE girdle for sure.

This is great!

Can’t wait to see the finished product. Glad to see the Motoiq team back on the Z32 platform.