Photos from Mercedes

A few months ago, the automotive media went nuts over the M139 engine from Mercedes. It’s the highest horsepower 2.0L engine ever to go into production making 416hp. That’s 208hp/L. While being emissions compliant. With a warranty. And it can run on crappy 91 octane while doing it all. 208hp/Liter is higher than any other production car on the market and rivals 600cc sportbikes in hp/L. Mercedes dropped some pics into the internet so let’s take a closer look.

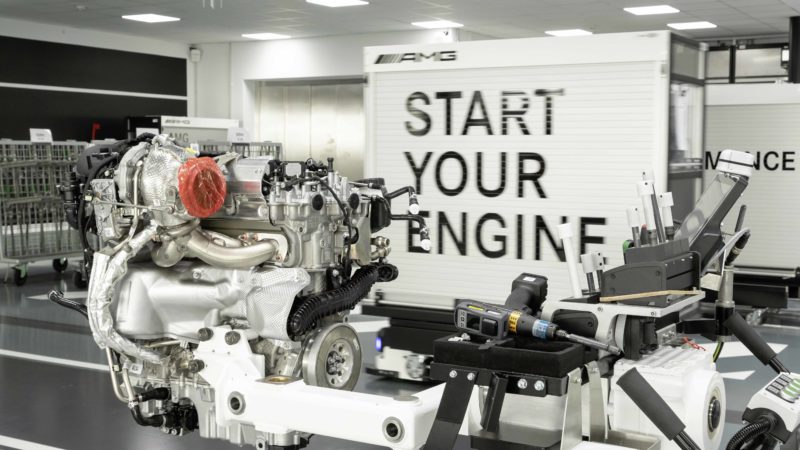

A little bit off-topic, but that electric torque gun sitting in the tray behind the engine is like ten grand. If it’s like the one I’ve used, it’s got wireless connectivity to a computer and it tracks every single fastener and the torque value attained. Of course, it also tells you if it torqued the fastener to within specification too. If you get a big red X error, the proper torque was not achieved. Smart tools like these are how to build quality standards are maintained in a manufacturing environment.

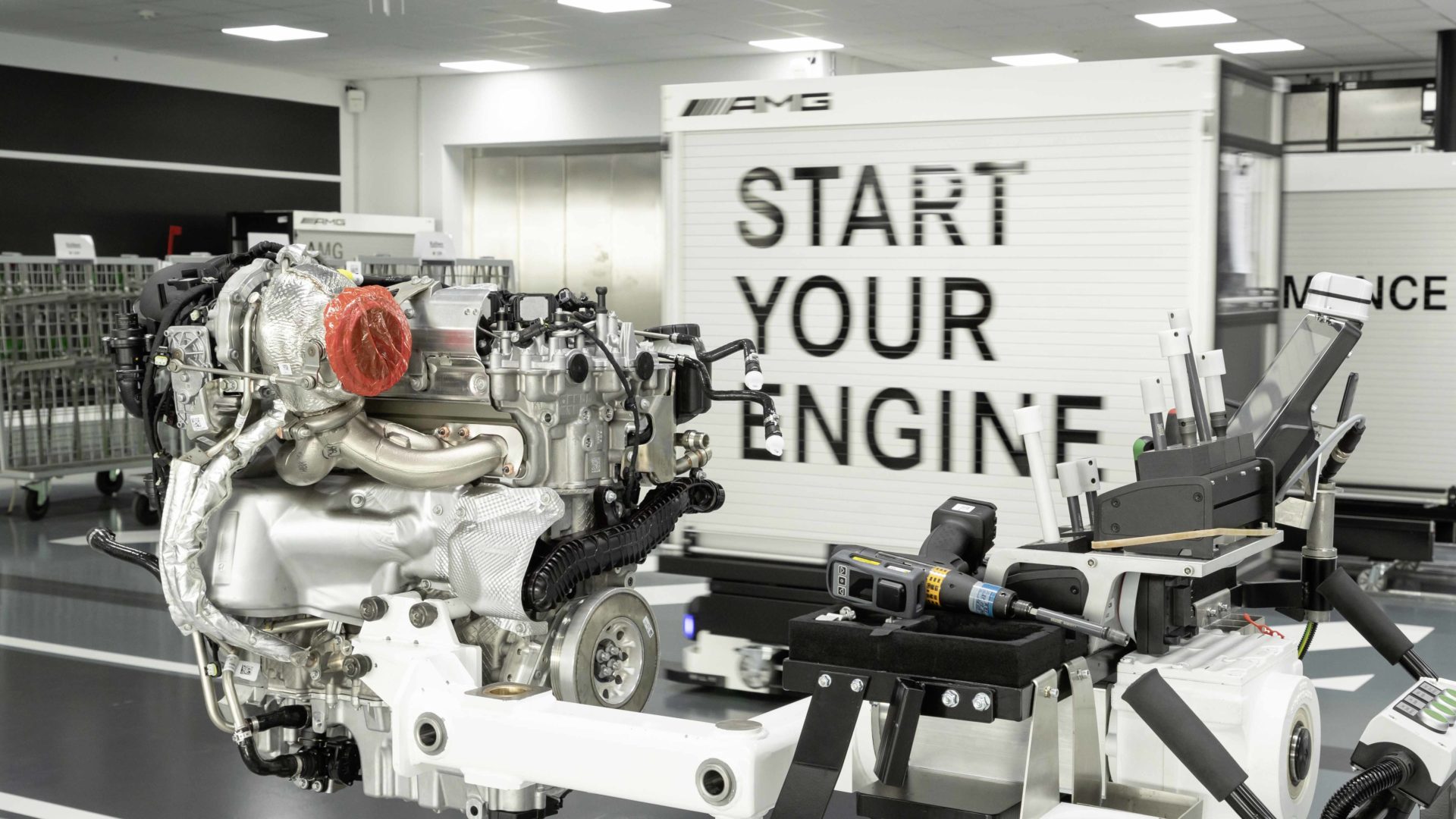

To make those big power numbers requires a lot of boost. A lot of boost on a small displacement engine means more lag. To combat lag, Mercedes uses a twin-scroll turbo. From the looks of it, I think it’s from IHI. Each turbo manufacturer does things a little differently which helps identify who made the turbo, like the joint between the wastegate actuator rod and wastegate arm. Also, the compressor housing to backplate joint. This turbo on the M139 also has ball bearings to reduce lag and improve transient response. A nice cast tubular log-ish manifold is the right mix for performance, cost, packaging space, and durability for an OEM application. My S2000 manifold concept is not too dissimilar. Check out the metal heat shield between the turbo and the plastic valve cover along with all the heat shielding underneath the manifold. I believe under the heat shielding are coolant passages. The turbo oil drain line and coolant line are also covered in insulation. Heat is thy enemy. Back to the turbo, there’s only one other carmaker using a v-band twin-scroll turbine housing with ball bearings in a production car that I’m aware of and that’s Ferrari. On the Ferrari 488, the turbos also have TiAl turbine wheels and abradable coatings on the compressor housing. The new Ferrari F8 will have a similar spec turbo. Anyway, the turbo on the M139 engine probably just slightly bigger wheels.

The use of a rotary electric wastegate actuator allows the use of a simple straight tie-rod instead of the 2-piece bendy linkage required with the use of a linear electric actuator. Electronics typically don’t like too much heat, so there’s a heat shield protecting part of the actuator. The turbine housing insulation wrap is typically seen on motorsports, but rarely on streetcars. Power = heat and the M139 is putting out a lot of hp/L…

This cutaway gives a peek at the two volutes of the twin-scroll turbine housing. Why is the entry to the catalytic converter not a simple dome? Because then, the exhaust flow would not be evenly distributed across the core and increase emissions. So, the shape of the entry into the catalytic converter is to force exhaust gasses through the part of the core on the inner side of the bend that would otherwise be bypassed due to the whole Newton’s first law thing. A couple of brackets help support the weight of that massive catalytic converter. Otherwise, all that weight would be transferred to the turbocharger and manifold and likely crack them over many heat cycles and time. Just eyeballing the size of the catalytic converter, it’s bigger than the turbo. It’s probably in the 6” diameter range assuming the inlet and outlet are around 3” diameter. Yeah, there’s no way to fit the catalytic converter under the car easily.

18 comments

While I agree getting that much HP out of a 2.0 is impressive I’m not that impressed by the technology involved, nothing here is new or groundbreaking. Where are the axial flow turbines? Where is the eSupercharger/Turbocharger? Where is the ignition prechamber/ jet ignition?

Mahle Powertrain has had all of that stuff working and running in race cars and test mules for the last 5+ years. I remember seing a VW golf 3 years ago with an 48v eSupercharged 1.2L three cylinder pushing 215 hp, way better fuel economy, and a ridiculous torque curve.

I realize new technologies need more testing but with electric cars pushing into the market you would think ICE technology would get off it’s ass and start trying new things.

It’s almost like making it work once in testing or on an F1 engine is completely different than industrializing it for mass production at reasonable cost. Note that 48V eSuperchargers are already on the market, even in AMG products. You need a whole 48V vehicle bus for them though, so it adds a ton of cost.

48 volt could mean a fully electrically operated valve train with tons of possibilities too.

The e-turbos are coming. Actually just saw this Garrett info pop up on their Facebook page: https://www.garrettmotion.com/electric-hybrid/garrett-e-turbo/

They just had to wait for the rest of the vehicle architecture to go to 48V. I doubt prechamber/jet ignition will make it to production anytime soon as it’s easier to just make a hybrid powertrain for mpg improvements.

Nice to know Garrett is getting into it too, theirs looks the most like the F1 MGUH. I knew BorgWarner had one and a bunch of small UK manufacturers have different offerings (the one I saw running was the Aeristech). I agree that 48V is a big step for automotive manufacturing but it isn’t even strictly necessary for e-super/turbocharging, Supergen already makes some that run of standard 12V: http://www.supergen.co.uk/default.asp?contentID=589

I think that jet ignition is not out of question, Mazda just put out an HCCI engine that is as, if not more, complex than jet ignition. It can also be done much simpler than how F1 does it, how they manage it with one injector per cylinder boggles the mind.

Well, Garrett is Ferrari’s F1 supplier 🙂

Also, as already noted, there are already 48V e-boosters in production. Audi has one.

there needs to be some sort of official multiplier (like in racing) for an FI’s engines output per displacement to be considered special. While 208hp/liter is pretty good for an emissions compliant engine, but comparing it to an NA 600cc sportbike engine is like comparing a roid’d up athlete to an excellent specimen of an athlete without roids…

That’s a BorgWarner “BB03” turbo. B03 frame size like the previous AMG 2.0l but with the new ball bearing center section. The dual torx/hex head compressor housing to backplate bolts and the forged rod ends with small E-clips for the actuator linkage are typical BorgWarner designs.

Thanks for the ID. I’ve been out of the turbo game for a while now. I’m use to the older BW turbos having the wastegate rod going through a block thing attached to the arm on a shaft and two nuts like on the EFRs. I always thought it was way overkill. Good to see they joined the rest of the turbo suppliers with the simple e-clip joint.

“The new Ferrari F8 will have a similar spec turbo. Anyway, the turbo on the M139 engine probably just slightly bigger wheels.”

Was this meant to say the M139 engine is probably the same as the F8/488 Ferrari sourced turbochargers?

Great article and love the tid bits about the torque gun and production considerations. Stuff you never see from the aftermarket.

Well, DobRahm pointed out the M139 uses a Borg Warner turbo and I THINK the Ferrari turbo is from IHI. Horsepower per turbo though, they are relatively close. The wheel diameters are probably within a few millimeter of each other.

Oh, and we’re all very eagerly awaiting a progress report on your S2000 GT3RS killer turned street car build! Your write ups are great, keep them coming.

Man…. S2k parts are getting hard to come by. And I’ve had to watch my budget. That said, I FINALLY got some engine bearings a couple weeks ago after waiting for half a year. I might have gotten the last set of King Bearings in North America for the S2k from Real Street Performance. I got to meet the head engineer/PhD at King Bearings a few months ago. Learned a LOT.

Feel free to share that knowledge with a bit here on MotoIQ about it! Look forward to that story.

I’m not surprised you’re finding S2k parts hard to come by. She’s getting to be an old bird and lots of people are already starting to ‘keep them 100% stock’ for resale purposes. Bringatrailer isn’t helping the price of used ones for folks like me

How far off are we from electronic wastegate actuators being produced by aftermarket performance companies?

While companies like MAHLE produce them they still seem OEM based, eg no bolt-on EFR/GTX units.

The industry-wide adoption doesn’t seem there,

I haven’t seen an ECU company offer out of the box support as they have with DBW

just an FYI, plenty of other twin scroll V-band IWG OEM turbos around. Starting with the BMW S63 all the way back in 2012 and all its subsequent iterations, and even the later N63TU2/R variants. All Garrett MGT22xx variants. The AMG M178 also uses a very similar setup to the M139 (due to it in fact, being quite literally twice the motor)

I worked a bit with the engineers who were the application engineers for the MGT22s on the S63. Those were not ball bearing though which is the primary difference with the newer turbo on this engine.