,

|

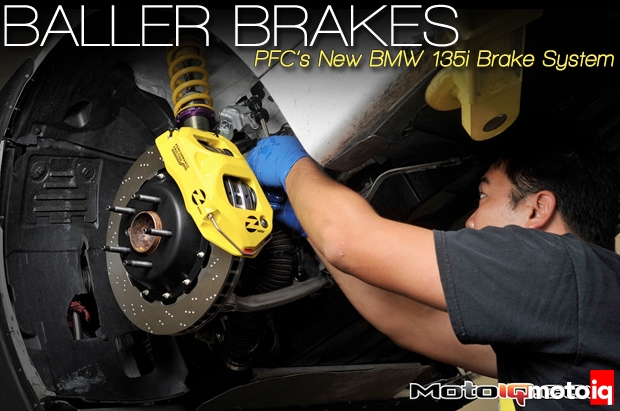

| Here you can see the orientation of the pads within the caliper. Like all monoblock calipers, the pads are loaded from the bottom. |

Performance Friction was selected as the company to develop the brake system for the car. Performance Friction incorporated some innovative solutions to meet Berk’s requirements to develop the ultimate brake system for the BMW 135i. Performance Friction is well known as the manufacturer of perhaps the best performance brake pads on the market. What is less known is that they are a leading supplier to the world of elite racing providing extremely high quality, well engineered brake systems. Many Nascar and ALMS cars run Performance Friction’s parts with a great deal of success. For the Berk car, Performance Friction applied this knowledge to engineer an ultra high performance street compatible brake system.

|

| This view shows the stainless steel pad abutments. The abutments prevent the steel brake pad backing plate from digging into the soft aluminum body. This eliminates wear on the caliper body and prevents the pads from getting stuck under load. |

What makes a good racing brake system typically isn’t something you want in your street car. Most racing brake systems are pretty elaborate needing a dual master cylinder hydraulic system that uses a balance bar, special pedal assembly and an adjustable proportioning valve. These parts are necessary because racing brake calipers are usually only available with 2-3 different piston sizes and the hydraulic proportioning of braking force must be highly adjustable to accommodate this. These parts are very expensive, adding thousands of dollars to the price of a brake system and require elaborate custom fabrication to provide rigid mounting points in a car.

|

| The Performance Friction rotor has an alloy hat making it about 3 lbs lighter than stock despite being larger and thicker. The rotor itself is made from a heat and wear resisting, heat treated, high carbon, copper, molybdenum iron alloy. |

For race cars where the brakes always function at a predictable temperature, there is no power assist as pedal effort is controlled through a mix of hydraulic system piston sizing, pedal leverage ratio and the coefficient of friction of the brake pads. Street cars must operate over a very broad range of conditions and power assist is a way that the brakes can be made to work over a wider range of temperatures for the average driver. For street cars you can also forget compatibility with ABS, EBFD, traction and stability control systems when using racing brakes.

|

| The rotor’s Direct Drive full floating system uses lugs to takes the shear load off of the mounting hardware. The wide lug face allows less bind and freer float than bolt centered floating rotors. |

|

| The bolts simply hold this retaining ring and are not in shear at all. You can also see the rotor’s fully machined inner diameter here. |