,

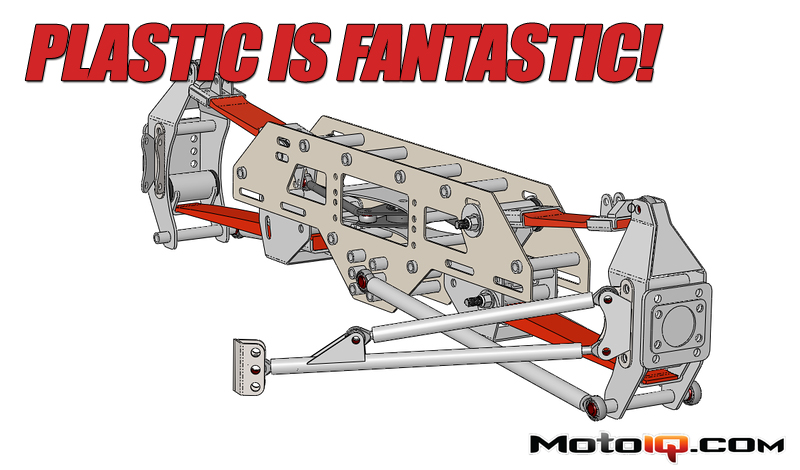

You may have noted that the upper arms have a more unusual shape – this is because we have to carry some additional suspension loads in addition to acting as a spring during cornering. Because this part functions as a control arm, we need to have enough material at both ends of the arm to attach it to the spindle mount and the subframe. In this case, we shape the part so that it flexes in the tapered section, and has enough thickness at the ends for the mounting brackets. Even though the part looks a little odd, you’ll see that we get a very even distribution of stress in the tapered area.

Here’s a model of one of the main springs, showing the taper. The arrows you see are a graphic representation of the setup for the analysis. The green arrows show the places that the spring is fixed. The purple arrows represent the loads applied. In this case, I’m applying 1600 lbs of force to the narrow end.

Here’s a model of one of the main springs, showing the taper. The arrows you see are a graphic representation of the setup for the analysis. The green arrows show the places that the spring is fixed. The purple arrows represent the loads applied. In this case, I’m applying 1600 lbs of force to the narrow end. After the load is applied, you can see how the spring deflects. Because of the taper, the deflection takes on a nice, circular curvature.

After the load is applied, you can see how the spring deflects. Because of the taper, the deflection takes on a nice, circular curvature. Here I’ve rotated the view a little so you can see what the stress looks like. The red area shows the highest stress, which is a little over 71,000 psi. Notice how the stress has a fairly even distribution.

Here I’ve rotated the view a little so you can see what the stress looks like. The red area shows the highest stress, which is a little over 71,000 psi. Notice how the stress has a fairly even distribution. This spring is the same stiffness as the tapered part. Since it is a constant rectangular cross-section, the thickness has been adjusted so that it has the same spring rate.

This spring is the same stiffness as the tapered part. Since it is a constant rectangular cross-section, the thickness has been adjusted so that it has the same spring rate. Here’s the analysis. Notice that it doesn’t bend in a smooth, circular curve like the tapered part. Most of the bending occurs near the fixed end (left side) of the spring.

Here’s the analysis. Notice that it doesn’t bend in a smooth, circular curve like the tapered part. Most of the bending occurs near the fixed end (left side) of the spring. In the rotated view, you can see how the stress is concentrated near the fixed end, where all the bending occurs. Note that the maximum stress (under the same 1600 lb. load) is a little over 103,000 psi, an increase of about 40 percent over the tapered part. Not only is this part more highly stressed, it’s also almost 10 percent heavier. Which part do you think will last longer?

In the rotated view, you can see how the stress is concentrated near the fixed end, where all the bending occurs. Note that the maximum stress (under the same 1600 lb. load) is a little over 103,000 psi, an increase of about 40 percent over the tapered part. Not only is this part more highly stressed, it’s also almost 10 percent heavier. Which part do you think will last longer?