,

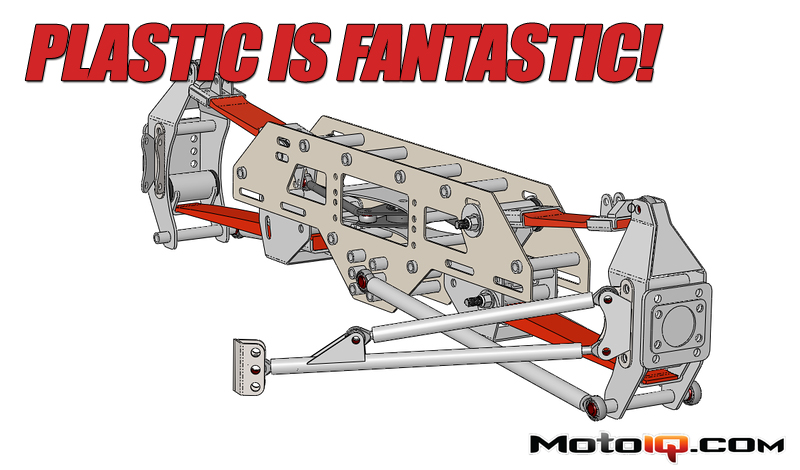

We wanted to make sure we had a quick way to change the spring rate and the ride height, and I wanted to make it pretty simple. At the track, time is usually of the essence, so I didn’t want to have to change springs every time we want to increase or decrease rate. By putting slots in the subframe plates, we’re able to slide the spring mounting brackets in and out, which shortens or lengthens the effective length of the spring. The springs are mounted in the brackets with an eccentric mechanism – just like a camber bolt. There’s a pivot on the end of the spring mount, and the eccentric bolt can be loosened and rotated to adjust the angle of the spring, changing the ride height. Camber is adjusted with eccentrics on the upper control arms, and we can change the roll centers by selecting different mounting points for the upper arms and/or lateral links. It’s going to be easy to tune – so easy that we’ll need to be careful. With this much adjustment it’s tempting to make more than one change at a time – something that should be avoided at all costs.

Here’s the upper arm. This is necessarily a little different, because we need to attach to mounts at both ends. The added thickness at the ends is necessary so we can securely attach the brackets, so this part is tapered through the middle section only. We can control exactly where and how the part bends by this shaping process.

Here’s the upper arm. This is necessarily a little different, because we need to attach to mounts at both ends. The added thickness at the ends is necessary so we can securely attach the brackets, so this part is tapered through the middle section only. We can control exactly where and how the part bends by this shaping process. Here’s how it bends – smooth and even curvature through the tapered section, but remaining straight on the ends.

Here’s how it bends – smooth and even curvature through the tapered section, but remaining straight on the ends. Here’s what the stress distribution looks like – nice and even, and it bends right where we want it – in the middle so that the mounting areas don’t get stressed.

Here’s what the stress distribution looks like – nice and even, and it bends right where we want it – in the middle so that the mounting areas don’t get stressed. Here’s how we adjust the spring rate and ride height. The rear lateral link is removed for clarity. You can see how the narrow end of the spring rides on a slipper mechanism at the spindle mount. This slipper mechanism is free to pivot so that the end of the spring is evenly loaded. The other end of the spring is mounted in a pocket that slides laterally on slots in the subframe. The spring mount, which is inside the pocket, pivots on the inner bolt, and ride height is adjusted with an eccentric on the outer bolt.

Here’s how we adjust the spring rate and ride height. The rear lateral link is removed for clarity. You can see how the narrow end of the spring rides on a slipper mechanism at the spindle mount. This slipper mechanism is free to pivot so that the end of the spring is evenly loaded. The other end of the spring is mounted in a pocket that slides laterally on slots in the subframe. The spring mount, which is inside the pocket, pivots on the inner bolt, and ride height is adjusted with an eccentric on the outer bolt. Here's a view from the rear, with the wheel mounted for reference. The spindle isn’t shown here, so you’ll just have to imagine it in between the wheel and the spindle mount. Here the spring is at its softest setting, with the mount slid all the way towards the center of the vehicle. You can see how the slipper mechanism at the spindle end pivots on bushings.

Here's a view from the rear, with the wheel mounted for reference. The spindle isn’t shown here, so you’ll just have to imagine it in between the wheel and the spindle mount. Here the spring is at its softest setting, with the mount slid all the way towards the center of the vehicle. You can see how the slipper mechanism at the spindle end pivots on bushings. Same view as above, with the spring carrier adjusted to full stiffness. I’ve also made the eccentric washer transparent here so you can see the adjustment slot.

Same view as above, with the spring carrier adjusted to full stiffness. I’ve also made the eccentric washer transparent here so you can see the adjustment slot.

At this point, the geometry model looks good and stable, the spring and arm designs look efficient and durable, the CRX looks to be on schedule at the body shop, the stars are in alignment, and we’ve got about 5 weeks to go. Now we’ve actually got to build the real thing! In the next installment, we’ll bring this model to life in steel and composites.