The rest of the insets are tapped into place. Very little force is needed to get them in place thanks to the temperature differential.

Here is the case with the insets installed. Once the inserts are in place, the cases are left for them to normalize to room temperature before the next machining process starts.

Once normalized, the cases are loaded into the CNC machine for the next operation. Notice how the cases are bolted together and are attached to the CNC machine via the transmission mounting surface. This distorts the cases like how they would be assembled.

Now the cases are decked to a flat surface. A register groove for a head gasket o-ring and coolant passages are also machined into the deck at this time.

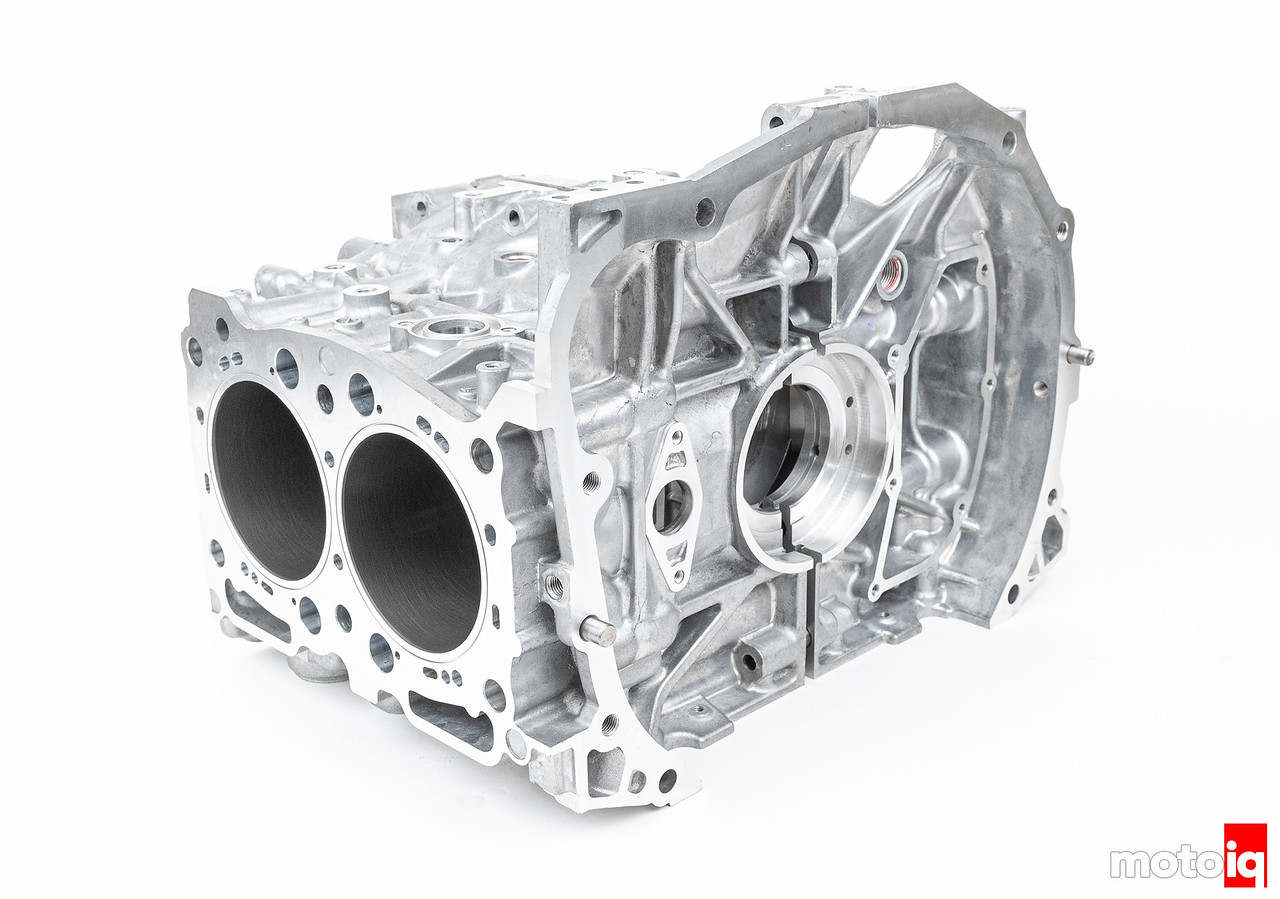

Here are the completed closed deck, big stud, O-ringed cases ready for the next machining steps. The insert fit is so perfect, you can’t even see them and the deck looks like a homogeneous piece.

Another stupid rumor in the Subaru community is that closed deck converted cases cause overheating. That is absolutely not true, at least not in IAG’s cases. OEM manufacturers make open decks because it’s better for easier manufacturing with more simple casting cores. Before when blocks were green sand cast, most engines were closed deck and they didn’t overheat. The way to avoid overheating is to have correct coolant passages in the closed deck and of course, IAG does this. IAG engines have stood the test in the harsh world of racing and have never had a failure related to a closed deck in many, many miles of track use.

8 comments

Hi Guys,

Love this article – I’ve got one question about the sequence of steps, specifically the CTP Cryogenics treatment step coming in after the torque plate hone/bore. If the tensile strength of the metals are going to be increased would that mean that the same torque rating on the head studs would create less distortion and negate some of the benefits of using a torque plate while machining?

Thanks,

Nick

No.

Our Cryogenic services should come after rough boring, if needed, but before final honing.. Torque ratings should not be altered from specs.. All building techniques should be done to the highest standards not matter what. It is the same as procuring the highest quality parts one can despite sending parts for DCT (deep Cryo Treatment) and other enhancements such as WPC or DLC..etc

As a note, we did not measure any dimensional differences in our cases before and after cryo treating.

Do you notice any differences between the machine work done by Outfront on the video build and and IAG on this one? if so which would you recommend for a Subaru engine build?

They are both high quality jobs but from seeing the process firsthand, IAG has more control over their processes and more state-of-the-art machining centers. IAG also uses deck reinforcements using the same cast metal as the block which is more thermally compatible with the original case. IAG has the 14mm stud option vs 12.5mm. IAG has the receiver groove for O-Rings. These are incremental differences.

What effect , if any does the wpc treatment have on oil retention on the bores?

The dimpled texture probably improves it.