,

Now, time for some exhaust hangers! If you're making a conventional steel exhaust, Vibrant sells exhaust hanger kits which are just solid stainless bar stock with barbs for keeping them aligned in exhaust hangers. Great stuff for a normal exhaust, but entirely too heavy a solution for this one, so I turned to this easy supply of lightweight steel tubing to make hollow hangers. This is, of course, an S13 power steering cooler loop.

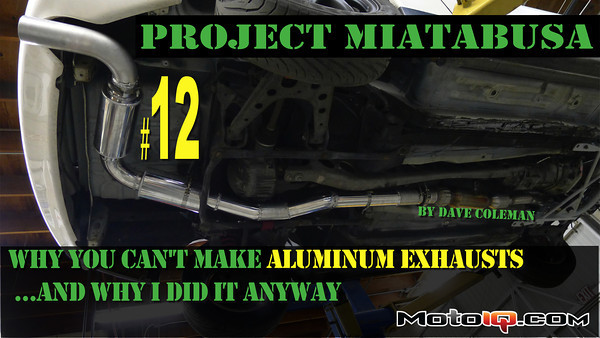

Doesn't look like such a dumb idea now, does it? Note how tight the exhaust is to the bottom of the car. On a trailer ramp or driveway, the frame rails will bottom before the exhaust does, eliminating one of the biggest sources of exhaust stress.

Positioning two Vibrant aluminum mufflers in a space designed for one transverse muffler was tricky. To leave room for bends, the forward muffler had to actually stick into the rear crossmember. Clearances are tight!

I had to teach myself how to weld aluminum to do this project. It's very different from welding steel, but really isn't nearly as hard as I had feared. My first bead literally fell off the tube when I was done. My second bead looked like it was left there by a seagull, but my third looked respectable and actually held two tubes together. After welding 3/4 of the way around a scrap piece of 3″ pipe, I was ready for the big time. Welding these two mufflers together were my fourth and fifth beads ever (you'll notice these welds didn't get a close-up…)

Look closely at the left muffler and you'll see it was trimmed short where it meets up with the 90. This was an effort pull the muffler back out of the rear crossmember.

Sometime around 1997 I stumbled into this hole-in-the-wall aircraft surplus shop in the back of some business park near Ontario airport, out in the hot, shitty Inland Empire of Southern California. For some reason, these giant T-bolt clamps, with these bizzare flanges welded to them, caught my eye. I have no idea what they were for, or what I was going to do with them, but I had to have them. Little did I know, almost 15 years later, I'd find a perfect use for them.

1 comment

Hey,

Do you have any updates on the reliability of this? Thanks!