,

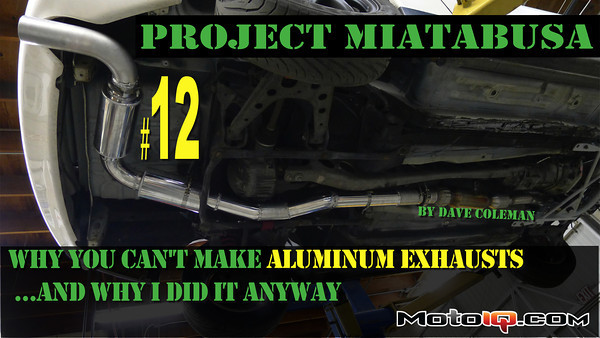

And suddenly the muffler hanger sits perfectly. (The sway bar bushings were being used to help make sure I always left a reasonable amount of room between the exhaust and the rear subframe brace.

One of the trickiest bits of making an aluminum exhaust is the fact that you (well, I…) can't easily tack it together in the car. I had to fit each piece, make little Sharpee marks on it to record the position, take the exhaust down, and re-position the parts on the bench so I could weld them back together.

Not only is this process tedious, but tiny changes in alignment between the fist setup under the car and when you actually weld it on the table can really start to add up. Welding one piece at a time let's you make little corrections with each new piece, but this last weld connected large sections that had been fabricated from opposite directions.

A slight change in alignment from that connecting weld in the middle of the exhaust ended up shifting the last muffler over a few degrees. This meant the 90-degree bend I had picked out for the tailpipe wasn't going to fit. I ended up having to add a tiny little sliver of a pie cut, and then try to weld it without just melting the living crap out of it. The result was not terribly pretty, but it should be good enough to keep the stinky gas on the inside.

All of Vibrant's aluminum tubing mandrel bends and mufflers come polished. The tailpipe actually came from MD Automotive's scrap pile. In truth, I prefer the low-bling, unpolished pipe for the one piece people will see from the outside.

Finally, a tight-fitting, plenty-of-ground-clearance, probably-not-going-to-break, multi metallurgical 2.5 to 2.7 to 3.0-inch exhaust!

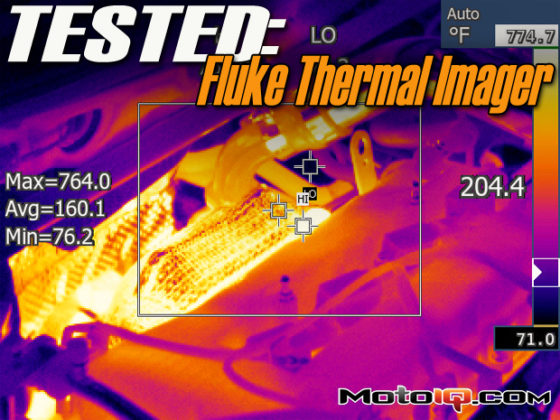

There is still a big open question about the durability of this solution, so I'll write an update after we have some miles on this. Heat treat is still a big question. Obviously the welds are annealed. The Vibrant bends may or may not be heat treated to T6. They have to be annealed to be bent in the first place, and they still seemed very soft when I was accidentally denting them, so they might not be heat treated at all. If the operating temperature of the exhaust is anywhere near the 500 degrees F where T6 and 0 heat treats have the same strength, it won't matter at all. If the exhaust is running cooler than that, I may consider getting the whole thing heat treated to T6. Once the car is running, we'll take some surface temperature measurements and see what we find.

9 pages of Miatabusa not enough for you? Hover over the “Projects” dropdown and click on “Project Mazda Miatabusa”

Sources

1 comment

Hey,

Do you have any updates on the reliability of this? Thanks!