,

Having narrowed down the issue to the control arm bushings, I started to seek possible upgrades. I’ve used polyurethane bushings on my Nissan SE-R and Mitsubishi Evo with great success. While doing the hot weather and NACA duct testing at Autoclub, I ran into a fellow S2k owner and MIQ reader who had installed urethane bushings on his car and highly recommended them. In researching options, there was really only one brand at the time making a bushing kit for the S2k that wasn’t insane JDM price gouging. However, there had been a couple reported issues with premature bushing failure of one particular bushing location. So, I gave the folks at BlackTrax Performance a call to see what they recommended. I’m already using their awesome baffled oil pan and they’re helping build Irene after all.

As luck would have it, they were just about to release a spherical suspension bearing kit in conjunction with Kingpin Machine. Wait? What? Spherical bearings for a dual purpose street/track car? But the car will be loud and ride harsh! That’s what a few folks told me but Jei over at BlackTrax assured me there would be no such issues. Besides, Phase 2 of the Project S2000 build was leaning towards the philosophy of the Porsche GT3RS which is to say fewer concessions to street friendliness in order to gain performance.

The kit has been in development and testing since 2012. The important bits are the 4140HT steel bearing sleeves and US manufactured bearings from either Aurora or New Hampshire Ball Bearing. To ensure proper fitment and optimum performance requires tight tolerances, tolerances tighter than the OEM specifications with the rubber bushings. Therefore, all the control arms must be sent in to BlackTrax for rework.

All of the control arms come back coated in black suspension paint. They look way better than rusty stock! The coating should help prevent future oxidation too.

All of the control arms come back coated in black suspension paint. They look way better than rusty stock! The coating should help prevent future oxidation too. You can see the spacers placed in the bearings here machined of 7075 aluminum. Yes, pricier than 6061 but also more durable and worth the extra cost. As I like to say, time is money and I’d rather not spend time replacing lower quality parts that wear out faster as that time spent ends up costing more than the money saved up front. Also check out the sleeve and bearing setup replacing the torn rubber big bushing at the end of the control arm. There is absolutely no play in this new setup.

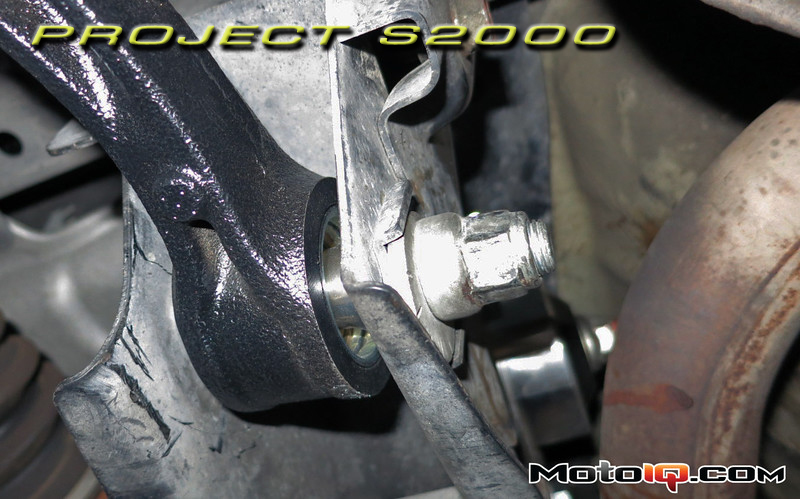

You can see the spacers placed in the bearings here machined of 7075 aluminum. Yes, pricier than 6061 but also more durable and worth the extra cost. As I like to say, time is money and I’d rather not spend time replacing lower quality parts that wear out faster as that time spent ends up costing more than the money saved up front. Also check out the sleeve and bearing setup replacing the torn rubber big bushing at the end of the control arm. There is absolutely no play in this new setup. This close-up shows the 4140 sleeve pressed into the arm and welded to make sure it stays in place. Now the reason for the requirement to send in the control arms is due to these sleeves. The sleeves are machined to a very tight tolerance, tighter than the factory specifications for the bores in the arms. Therefore all the bores are machined to a matching tight tolerance to ensure a perfect fit for the sleeves. If the sleeves were designed to fit in the stock bores with larger tolerances, then it is highly likely that many of the sleeves would be loose in their bores, negatively impacting performance and perhaps even leading to premature failure.

This close-up shows the 4140 sleeve pressed into the arm and welded to make sure it stays in place. Now the reason for the requirement to send in the control arms is due to these sleeves. The sleeves are machined to a very tight tolerance, tighter than the factory specifications for the bores in the arms. Therefore all the bores are machined to a matching tight tolerance to ensure a perfect fit for the sleeves. If the sleeves were designed to fit in the stock bores with larger tolerances, then it is highly likely that many of the sleeves would be loose in their bores, negatively impacting performance and perhaps even leading to premature failure.

Howard at Technosquare handled all the installation duties for the control arms; he is the only person I trust wrenching on the car. I trust him even more than myself wrenching on the car as he knows all the little tricks. With the lower front control arm installed, you can see why the new big bearing at the end of the arm is so important to handling. The slop in the stock bushing at this location allowed the back of the control arm to move around which therefore changed the steering angle of the tire. Now you can understand why my steering was unstable mid-corner with the worn bushing; the control arm was moving around changing the steering angle. With the new spherical bearing, that free play and undesired movement is completely eliminated.

Howard at Technosquare handled all the installation duties for the control arms; he is the only person I trust wrenching on the car. I trust him even more than myself wrenching on the car as he knows all the little tricks. With the lower front control arm installed, you can see why the new big bearing at the end of the arm is so important to handling. The slop in the stock bushing at this location allowed the back of the control arm to move around which therefore changed the steering angle of the tire. Now you can understand why my steering was unstable mid-corner with the worn bushing; the control arm was moving around changing the steering angle. With the new spherical bearing, that free play and undesired movement is completely eliminated. This is one of the rear upper arms installed. You can see how the spacers locate the arms.

This is one of the rear upper arms installed. You can see how the spacers locate the arms.