,

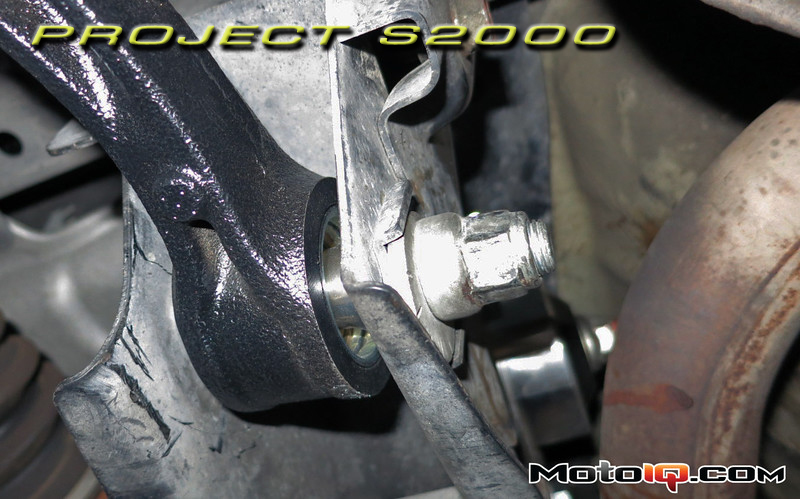

The rear shock mounting location in the lower control arm also uses a spherical bearing for no play, stiction, or binding. The lack of stiction allows for smoother operation.

The rear shock mounting location in the lower control arm also uses a spherical bearing for no play, stiction, or binding. The lack of stiction allows for smoother operation.You may remember from a long time ago, in a car project timeline far far away…. I installed Hasport engine mounts as part of kicking off Phase 2 of the Project S2000 build. At that time I also obtained a set of Hasport rear differential mounts. The idea was to install these at the same time as an upgraded rear differential. Well, the timeline for getting a new differential has been pushed back due to costs, so I figured now was as good of a time as any to install the rear diff mounts while the rest of the car was being worked on.

The Hasport rear diff mounts feature billet machined mounts for the street-rated 62A durometer urethane inserts. The stock mounts have massive voids in the bushings allowing significant movement. As you can see with the solid urethane mounts, no voids. The only movement will come from the deformation of the urethane itself. As I still do drive my car mostly on the street and I’m at nearly stock power levels, I opted for the softest 62A durometer mounts. There are 3 other levels of higher stiffness depending on your power levels and tolerance for noise.

The Hasport rear diff mounts feature billet machined mounts for the street-rated 62A durometer urethane inserts. The stock mounts have massive voids in the bushings allowing significant movement. As you can see with the solid urethane mounts, no voids. The only movement will come from the deformation of the urethane itself. As I still do drive my car mostly on the street and I’m at nearly stock power levels, I opted for the softest 62A durometer mounts. There are 3 other levels of higher stiffness depending on your power levels and tolerance for noise.

The front pair of diff mounts install right next to the driveshaft where the shaft connects to the differential. The mounts have to support the weight of the differential along with resist the torsional loads from the driveshaft. If you imagined just the differential connected to the driveshaft and floating in space, as the driveshaft spins so would the differential with it. One job of the mounts is to keep the differential in place.

The front pair of diff mounts install right next to the driveshaft where the shaft connects to the differential. The mounts have to support the weight of the differential along with resist the torsional loads from the driveshaft. If you imagined just the differential connected to the driveshaft and floating in space, as the driveshaft spins so would the differential with it. One job of the mounts is to keep the differential in place.

The rear pair of diff mounts are tasked with the same jobs of the fronts of course. Another one of the jobs of the rear diff mounts is just to resist any motion of the differential with respect to the chassis. As we know from physics and Newton’s first law, something in motion will stay in motion in a straight line until some force acts on it. So the mounts transfer forces from the car chassis to the differential to get the differential to follow the car. With the stock soft and squishy mounts, in quick transitions, the rear differential will lag behind the chassis when turning.

The rear pair of diff mounts are tasked with the same jobs of the fronts of course. Another one of the jobs of the rear diff mounts is just to resist any motion of the differential with respect to the chassis. As we know from physics and Newton’s first law, something in motion will stay in motion in a straight line until some force acts on it. So the mounts transfer forces from the car chassis to the differential to get the differential to follow the car. With the stock soft and squishy mounts, in quick transitions, the rear differential will lag behind the chassis when turning. Project S2000, while just short of 68k miles at this point, is pushing 10 years old. As another ‘while the car is down’ kinda thing, I decided to replace the coil packs and spark plugs along with doing a valve adjustment. On a 10 year old car, the stupid plastic clips on the wiring harness going to the coil packs will snap like pretzels. Blame that on getting baked in the confines of the valve cover for many years. Fortunately, it’s a snug fit so even with the clips broken to properly secure the connectors to the coil packs, they all stay in place well. That and the addition of some zip ties to really hold them in place.

Project S2000, while just short of 68k miles at this point, is pushing 10 years old. As another ‘while the car is down’ kinda thing, I decided to replace the coil packs and spark plugs along with doing a valve adjustment. On a 10 year old car, the stupid plastic clips on the wiring harness going to the coil packs will snap like pretzels. Blame that on getting baked in the confines of the valve cover for many years. Fortunately, it’s a snug fit so even with the clips broken to properly secure the connectors to the coil packs, they all stay in place well. That and the addition of some zip ties to really hold them in place.Onto the driving impressions (after an alignment at West End of course), let’s start with the spherical bearing suspension kit from BlackTrax Performance. My very first impression: SMOOTH. Yes, it completely surprised me too! Going over the first set of bumps, the way the suspension reacts now is very smooth. Yes, the car was harsher with the stock, albeit, worn out control arm bushings. But it all makes sense; with the stock bushings, the control arms would react initially to a hard force input through the suspension by deforming the bushings until they reached the limit of deformation. Then they would become essentially solid creating a step input of force into the chassis creating harshness. As the bushings were quite worn out (probably accelerated by the high-grip Nitto NT01s….), they probably allowed the control arms to move far enough out of the intended range of operation to create some binding too. With the new spherical bearing setup, there is absolutely no free play. Therefore, all the forces transmitted through the tires goes directly into actuating the KW Clubsports. This also creates a much more responsive chassis in turning as there is no longer a time lag between turning force inputs and the chassis starting to turn. Before, there would be some time lag due to forces causing the stock bushings to deform. With the spherical setup, there is no more deformation and therefore no more lag in reaction. Did I mention how smooth the suspension feels now? It’s really quite amazing.