,

From Gates, we’re using its T215RB timing belt (bottom) and K060763RB belt (top) for the accessories.

In the 90s, Toyota and Gates specified an aramid (kevlar) tensile cord for the Supra’s belt because, even in stock trim, the 2JZ-GTE needed the added insurance against any stretching and degredation of its timing belt. Getting fiberglass of appropriate strength to handle the shock loading wasn’t easy then, and still isn’t today.

According to Herbert, the kevlar worked nicely at the time, but its one drawback was it showed great tensile (resistance to separation) strength right up to the moment it would fail, where it would fail completely. “Fiberglass, like the upgraded fiberglass tensile cord in our racing construction, actually has better tensile strength than Kevlar and will hold even longer. And if it fails it will degrade slowly over time rather than completely abandoning you,” says Herbert.

The OE Supra timing belt (left) vs a Gates RPM timing belt for the 2JZ (right).

The OE belt for the 2JZ-GTE would have come standard with HSN (highly saturated nitrile) rubber, which is better than the neoprene belts from the 80s, but Gates takes it a step further with their racing belts. “Our Gates RPM constructions makes use of a premium quality HNBR rubber, which undergoes a peroxide curing process for longer life, better heat resistance and exceptional chemical resistance,” says Herbert. “Heat resistance is crucial because it means the rubber compound won’t see a degradation in elasticity. This means the belt will continue to wrap the pulleys with a perfect fit—with no cracking or breaking—for countless heat cycles.”

The chemical resistance is important in case of an oil or coolant leak, which can also cause a timing belt failure over time. To top it off, Gates reinforces the rubber with kevlar fiber for greater tear resistance and general strengthening, rather than for its tensile strength, providing more resistance against tooth shear. “With all of the horsepower this Supra will be seeing, tooth shear could be a serious concern. But with our belt, the same qualities that keep the Kevlar from tearing a bullet proof vest are also exploited to keep the timing belt’s teeth firmly in place, “ says Herbert.

“The Kevlar-reinforced Gates RPM tooth jacket is thicker, stronger and simply more bad-ass than anything you’d find on a stock belt. What it comes down to is three times the heat resistance and 300% more strength than most standard timing belts. This Gates belt should easily be good for over 60k miles—the standard interval for a stock Supra with a factory belt—even for this car with over 800whp turning it,” says Herbert.

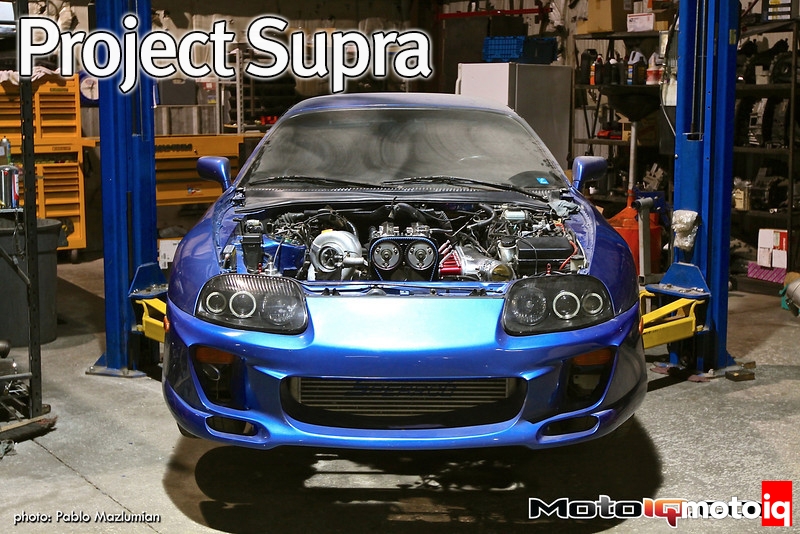

As featured in Part 4, here’s our Precision 6766 dual ball-bearing turbo ready to do some sucking as it dog-piles our lovely PHR manifold.

Looking at the PT6766 from the back gives us a better picture of where our Precision 46mm wastegates will be located.

The engine is in the car, at last! Here’s one last look at the PHR manifold before the turbo covers most of it. The heat-insulating wrap and spray comes from Thermotec, which is also covering Swain Tech’s “White Lightning” coating. For more detailed info check out Part 5.