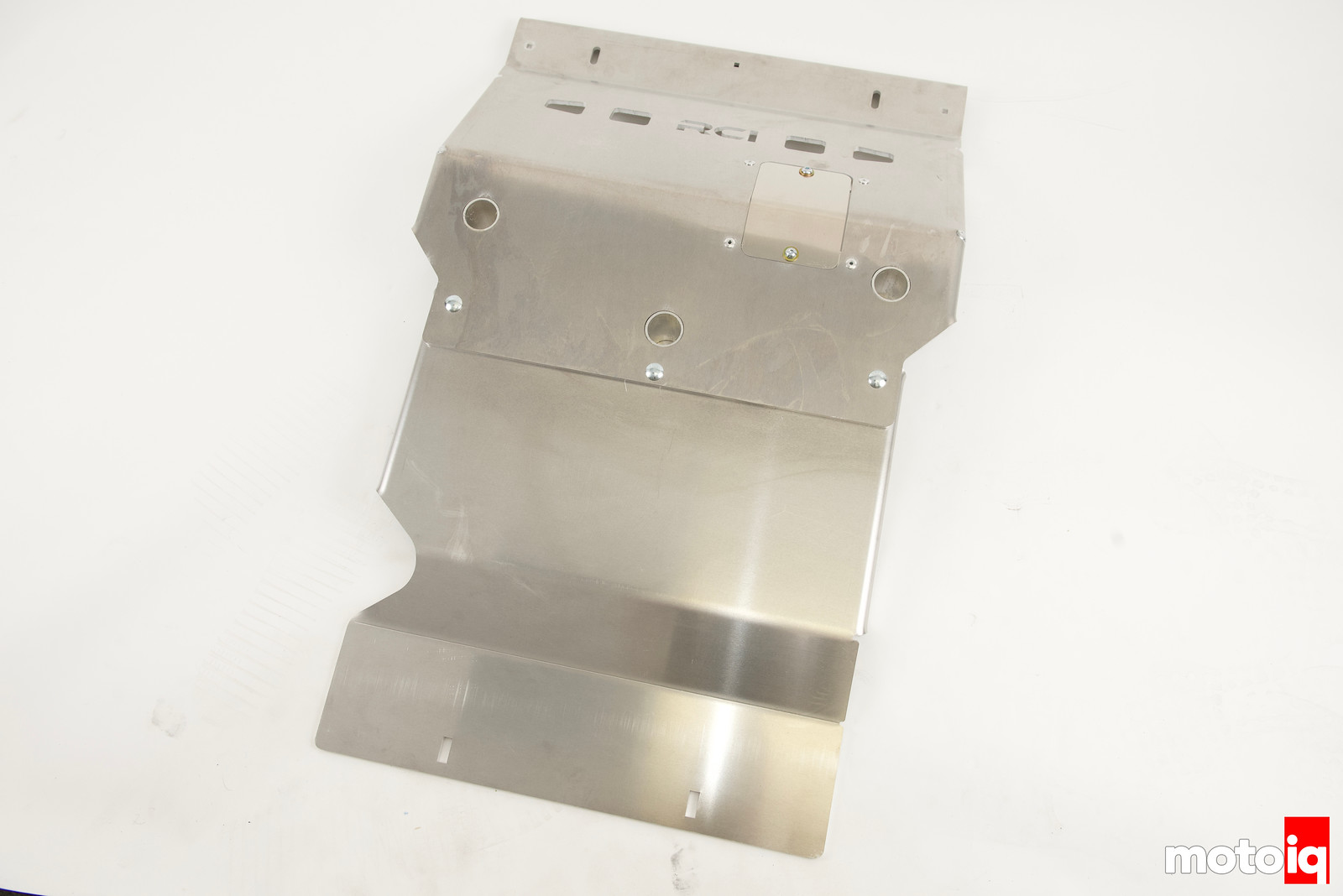

The rear part of the skidplate is bolted onto the front. Even the front section alone is bigger than the stock skid plate.

These sturdy stand-offs tig welded to the skidplate are to mount the skidplate to the chassis using the existing holes in the frame and the original mounting points.

This hatch allows for access to the oil filter without removing the skid plate. This is how Toyota should have done it in the first place. This alone is a good reason to get the skidplate!

The RCI skidplate bolts right in place of the factory one. RCI includes spacers for trucks with dropped differentials and we used them. Spacers are not such a hassle now because we don’t have to keep removing the skid plate to change the oil. We started the tightening process at the front where the stand-offs are because they are slotted so we could move everything around to line stuff up and get the other bolts going.

After the bolts were started at the standoffs, we moved the skid plate around and lined up, and started all the bolts. The rearmost mounting points use existing holes in the cross-member with long bolts and big washers. Once all the bolts were started, we tightened them all full and our installation was complete.

Our RCI skidplate looks great, is much stronger than stock, protects the bottom of the truck way better, makes oil changes a breeze (the notch on the rear left area of the skid plate is to access the oil drain plug without having to drop the skidplate as well) probably reinforces and stiffens the frame and cleans up the underbody aerodynamics as well. You can see the frame rail to frame rail protection the underbody now has. This is another mod we should have done a long time ago! If you are a hardcore off-roader, RCI makes rail sliders and full underbody armor for the Tundra too.