,

The front rotors are huge 355mm x 32mm Stoptech Aerorotors which are much bigger than the 316mm x28mm stock parts. The Aerorotors have CFD flow optimized internal vanes for good cooling. Aerorotors have optimized metallurgy for long wear and brake pad compatibility. The Aerorotors have 7075 T6 aluminum alloy hats which are anodized for corrosion resistance. The alloy hats make them lighter even though they are a lot bigger. At 18.3 lbs each they are almost 5 lbs lighter per rotor than stock!

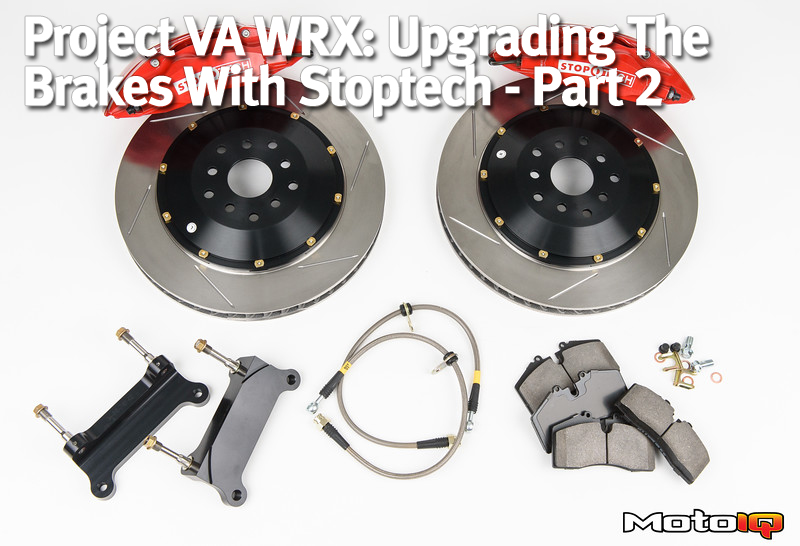

The front rotors are huge 355mm x 32mm Stoptech Aerorotors which are much bigger than the 316mm x28mm stock parts. The Aerorotors have CFD flow optimized internal vanes for good cooling. Aerorotors have optimized metallurgy for long wear and brake pad compatibility. The Aerorotors have 7075 T6 aluminum alloy hats which are anodized for corrosion resistance. The alloy hats make them lighter even though they are a lot bigger. At 18.3 lbs each they are almost 5 lbs lighter per rotor than stock! The Aerorotors are fully machined for good balance and are free floating with movement allowed on the hats to minimize piston knock back. This movement allows for factors such as bearing play and flex in the knuckle so they do not knock the caliper pistons back into the caliper. Caliper piston knockback, causes an intermittent mushy and long brake pedal and is pretty annoying under track conditions. The free floating rotors have anti rattle hardware which uses a conical Inconel washer to put some preload on the rotor so it can't just freely rattle. The Stoptech rotor hat has vanes that pump air between the hat and rotor and reduce contact area. This reduces heat transfer to the hub and allows a little more cooling air to the outside face of the rotor.

The Aerorotors are fully machined for good balance and are free floating with movement allowed on the hats to minimize piston knock back. This movement allows for factors such as bearing play and flex in the knuckle so they do not knock the caliper pistons back into the caliper. Caliper piston knockback, causes an intermittent mushy and long brake pedal and is pretty annoying under track conditions. The free floating rotors have anti rattle hardware which uses a conical Inconel washer to put some preload on the rotor so it can't just freely rattle. The Stoptech rotor hat has vanes that pump air between the hat and rotor and reduce contact area. This reduces heat transfer to the hub and allows a little more cooling air to the outside face of the rotor. Stoptech Rotors are available with grooves or drilled. These features allow the vaporized pad material to be swept away from the boundary layer between the pad and the rotor formed under hard braking. This contributes to better bite. The grooves also help the rotor shed water under wet conditions. We prefer grooves to drilled rotors as they are much more resistant to cracking.

Stoptech Rotors are available with grooves or drilled. These features allow the vaporized pad material to be swept away from the boundary layer between the pad and the rotor formed under hard braking. This contributes to better bite. The grooves also help the rotor shed water under wet conditions. We prefer grooves to drilled rotors as they are much more resistant to cracking.  The radial mount calipers are adapted to the factory ear mounted knuckles with this adaptor bracket that is machined from strong 7075 billet aluminum. 7075 is much stronger than your typical 6061 and is generally a better choice when the material doesn't have to be welded or formed. Radial mounted calipers are better because the caliper mounting posts are as close as possible to the rotor so any canting moment caused by braking torque is reduced to the minimum.

The radial mount calipers are adapted to the factory ear mounted knuckles with this adaptor bracket that is machined from strong 7075 billet aluminum. 7075 is much stronger than your typical 6061 and is generally a better choice when the material doesn't have to be welded or formed. Radial mounted calipers are better because the caliper mounting posts are as close as possible to the rotor so any canting moment caused by braking torque is reduced to the minimum.  The brake pads are Stoptech's street performance pads. We have found these pads to be relativity long lasting, clean and quiet on our other projects with still giving acceptable track performance when used with a big brake kit. That is one of the advantages to big brakes, you can get acceptable track performance with less aggressive streetable brake pads. Stock brakes require aggressive not streetable pads for track use and usually don't have the thermal capacity to keep it up for long even with high temperature optimized pads. The big pads have about 40% more surface area than stock.

The brake pads are Stoptech's street performance pads. We have found these pads to be relativity long lasting, clean and quiet on our other projects with still giving acceptable track performance when used with a big brake kit. That is one of the advantages to big brakes, you can get acceptable track performance with less aggressive streetable brake pads. Stock brakes require aggressive not streetable pads for track use and usually don't have the thermal capacity to keep it up for long even with high temperature optimized pads. The big pads have about 40% more surface area than stock. To complement our big brakes we went with Stoptech's braided steel brake lines. The braided lines are teflon coated and resist expansion when pressure is applied. By not ballooning under pressure, they make an improvement in brake pedal feel and firmness. They also improve ABS operation. Stoptech lines are DOT approved so they pass the safety whip test.

To complement our big brakes we went with Stoptech's braided steel brake lines. The braided lines are teflon coated and resist expansion when pressure is applied. By not ballooning under pressure, they make an improvement in brake pedal feel and firmness. They also improve ABS operation. Stoptech lines are DOT approved so they pass the safety whip test.