Evo’s have a pretty good cast aluminum rear subframe from the factory. So when an Evo IX was brought in to have its subframe changed out to a lightweight part from Magnus Motorsport, our interest was piqued. Just how much lighter could a fabricated tubular chromoly part be compared to the pretty cool stock aluminum part and were they any drawbacks from it? We had to see.

The Magnus Motorsports part is on the left and it replaces the cast aluminum parts on the right. On the Magnus part, the differential mount is integrated into the crossmember while on the OEM part, a heavy cast iron mustache bar is used to support the diff. We don’t understand why Mitsubishi would spend money on all of this aluminum only to make a part of the crossmember assembly out of super heavy cast iron! The Magnus crossmember is fabricated from tig welded 4130 chromoly tubing and is claimed to improve torsional stiffness. It does look like it would be a lot stiffer than stock. The subframe is finished in black powdercoat.

We weighed the Magnus Motorsports crossmember and it came in at 21.15 lbs. That’s pretty darned light.

The stock stuff it replaced weighed a portly 55.83lbs! The Magnus part is less than half the weight and saves 34.68 lbs! This is a huge amount of weight and its stiffer as well!

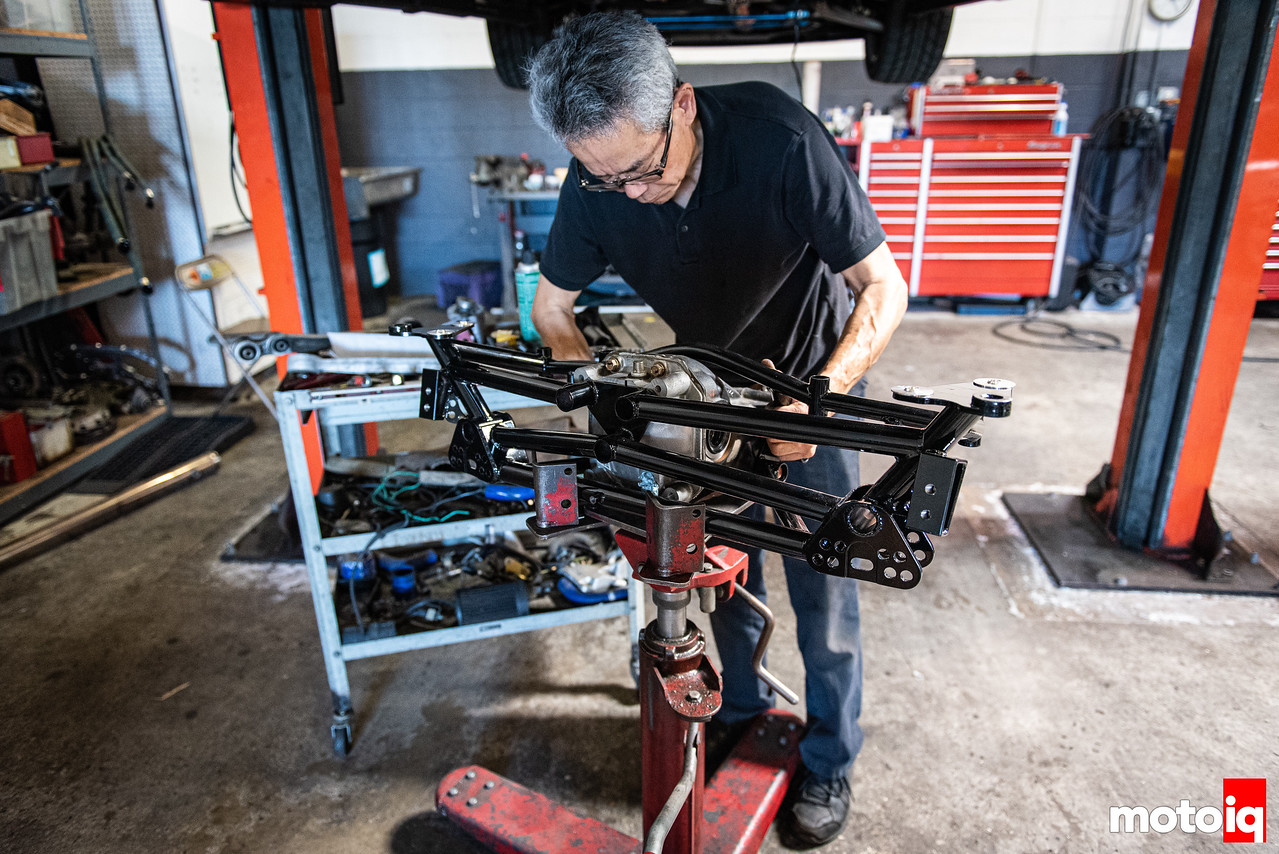

We removed the stock subframe and differential and installed the diff on the new subframe. The Magnus subframe is designed to fit the stock diff or the stronger 94 and later 3000GT rear diff. The differential is solidly mounted now and cannot twist or move under load. This is easier on the axles and driveshaft and eliminates the pounding thumps and wheel hop. This helps reduce 60 foot times.

4 comments

Are rigid collars worthwhile on something like a GC Impreza that has a rubber bushing where the rear subframe mounts to the body? Relatedly, is there any disadvantage to a permanent installation of any of the various “lock-down” shoulder bolts in the same application?

No they work great, I use the Whiteline locks myself.

as a GC owner who also has the Whiteline lockdown bolts, I’m also very intrigued by the improvements made by these Spoon Rigid collars and their replicas.

Not to mention the improved fatigue life of steel. If you have any kind of off-road excursion those aluminum parts fail catastrophically. I have seen aluminum front spindles sheered in two.