,

The rear brakes are fairly substantial. Considering the vehicle has a mid-engine layout, the weight distribution might be in that 40%F/60%R range. A brake duct hose is routed to the rear rotor and the sheet metal shield helps to make sure as much of the air as possible goes through the rotor. Notice all the suspension joints are heim joints, as you would expect in a purpose built race car. AST dampers keep the car suspended.

The rear brakes are fairly substantial. Considering the vehicle has a mid-engine layout, the weight distribution might be in that 40%F/60%R range. A brake duct hose is routed to the rear rotor and the sheet metal shield helps to make sure as much of the air as possible goes through the rotor. Notice all the suspension joints are heim joints, as you would expect in a purpose built race car. AST dampers keep the car suspended. Here is the adjustable blade-type rear sway bar. Check out the handle-bar style clamping bracket thingy (what do you call that?!) to hold the cable used to adjust the sway bar.

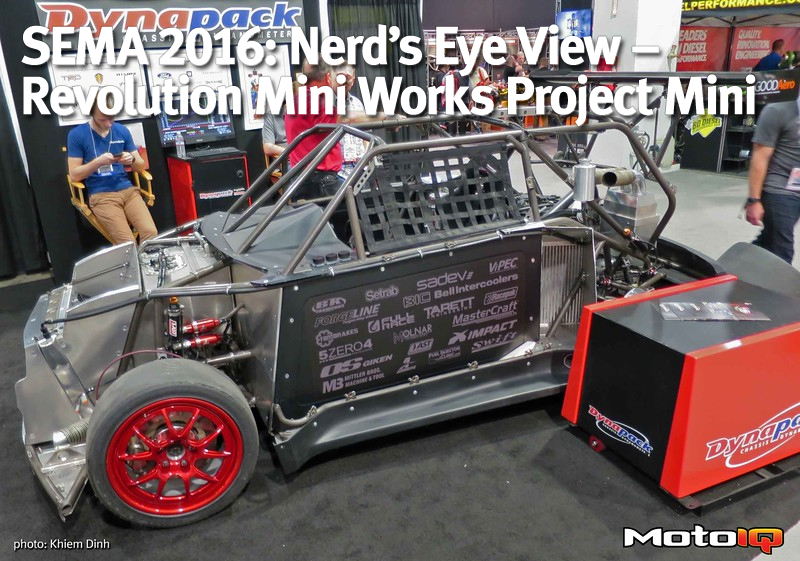

Here is the adjustable blade-type rear sway bar. Check out the handle-bar style clamping bracket thingy (what do you call that?!) to hold the cable used to adjust the sway bar. Powering this oversized crazy kart is a Mini 1.6L engine stroked to 2.0L. A Borg Warner EFR7163 twin-scroll turbo provides the boost. The head is built to handle 9000rpm and the engine puts out over 500hp; the engine can make more, but it’s limited by the Sadev transmission. Thermal management is always a concern on a race car, so all the exhaust components are ceramic coated. From a flow standpoint, check out the generous radius bends for the compressor outlet pipe, exhaust manifold, and the downpipe to minimize pressure drops.

Powering this oversized crazy kart is a Mini 1.6L engine stroked to 2.0L. A Borg Warner EFR7163 twin-scroll turbo provides the boost. The head is built to handle 9000rpm and the engine puts out over 500hp; the engine can make more, but it’s limited by the Sadev transmission. Thermal management is always a concern on a race car, so all the exhaust components are ceramic coated. From a flow standpoint, check out the generous radius bends for the compressor outlet pipe, exhaust manifold, and the downpipe to minimize pressure drops. Air gets to the compressor inlet of the turbo by way of this air box grabbing cool and fresh air. It looks to be sealed so that some positive ram air pressure can build up too.

Air gets to the compressor inlet of the turbo by way of this air box grabbing cool and fresh air. It looks to be sealed so that some positive ram air pressure can build up too. Notice the compressor inlet tube has a bit of a trumpet shape to it. With the air box being rectangular in shape, I’m wondering if it uses a panel air filter and then a nice air trumpet inside to guide air into the turbo. Check out the turbo oil and water lines wrapped in thermal insulation to protect the hoses from heat to improve reliability. Way back in the day on my first car that I put a turbo on, I had a turbo rubber coolant line crack after about five years of hardening due to heat exposure. This left the car spewing coolant on the ground at a gas station. I managed to baby it home before leaking too much coolant and overheating.

Notice the compressor inlet tube has a bit of a trumpet shape to it. With the air box being rectangular in shape, I’m wondering if it uses a panel air filter and then a nice air trumpet inside to guide air into the turbo. Check out the turbo oil and water lines wrapped in thermal insulation to protect the hoses from heat to improve reliability. Way back in the day on my first car that I put a turbo on, I had a turbo rubber coolant line crack after about five years of hardening due to heat exposure. This left the car spewing coolant on the ground at a gas station. I managed to baby it home before leaking too much coolant and overheating.