,

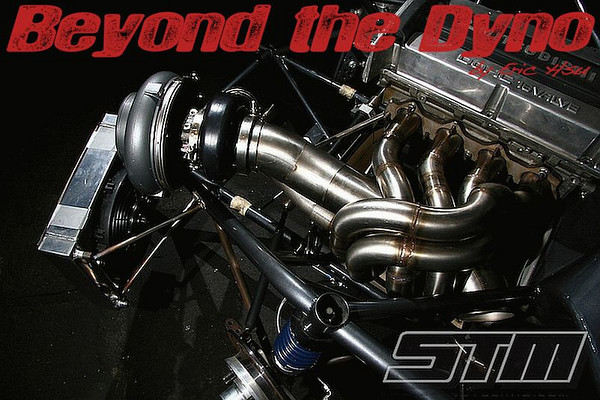

Bam @ STM started first with fabricating the exhaust manifold using a Burns Stainless 321 stainless merge collector. One of the reasons Mike wanted the giant Garrett GT45 relocated was to keep the body lines clean. Andre and STM wanted to fabricate a new header to meet his specificiations.

The GT45 was temporarily bracketd to the chassis while Bam fabricated the header and the downpipe simultaneously. A TiAL V-band turbine housing was used for a weight savings of 8kg (17.6lbs.). The TiAL housing probably doesn’t pass burst testing, but this is a race car after all.

Despite being a tube frame chassis, there was still a limited space for a long tube header, merge collector, and a turbo the size of a medium pizza. The EVO’s natural hood line is very short due to the transverse engine mounting. Mike wanted to keep the proportions of the body work similar to stock so space was limited.

The 4G63 has oval ports so Bam broke out the oxy-acetylene to form the tubes to match the ports in the flange.

Here’s the turbo and exhaust manifold completed. The hefty pizza turbo is supported by a couple of heim joints braced to the chassis tubes.

Plenty of stainless steel goodness! The compressor inlet sits inside of a shroud which is where the RH headlight would be.

With the exhaust manifold completed, Bam could finish the bottom section of the downpipe. Keeping the exhaust outside of the cabin was paramount since the engine runs on Methanol. Trust me guys, the last thing you want is a whiff of Methanol after a burnout. Your eyes will burn like you’ve never felt and your mucous membranes feel like they are melting. Another problem was that the front wheels wouldn’t turn full lock with the 4″ downpipe so Bam’s solution was to scallop the factory shell to clear the downpipe.

BTW, the EVO 8 shell from the firewall and back is 100% steel.

BTW, the EVO 8 shell from the firewall and back is 100% steel.