,

With the new turbo location, the old intercooler was also redesigned. This fabricated work of art that some people might call an intercooler was designed and fabricated by Jono Climo at Motorsport Fabrications in Auckland, NZ. It’s easy to miss some of the attention to detail. One that pops out at me is the formed section at the base of the charge inlet. It looks like Jono may have built a die to form that small section of aluminum to perfection.

Here’s the intercooler mounted in place after completion. The tank in front of the wheel is the dry sump oil tank. From the looks of it, it appears to be a Peterson Fluid Systems unit. The Peterson tanks are great because they can be disassembled and cleaned in the unfortunate case of engine failure.

The original plastic Jaz tanks just didn’t look right after everything else was cleaned up so Bam designed a custom two section tank that slotted right in between the intercooler and engine. One side acted as a fuel cell for the Methanol and the other side was for the intercooler water/ice mixture. How’s that for excellent packaging? The tanks was fabricated by Jono @ Motorsport Fabrications.

Gas Clamps were used from Gas Motorsports in Australia. They appear to be similar to a Wiggins clamp in form and function, but are more than likely more cost effective.

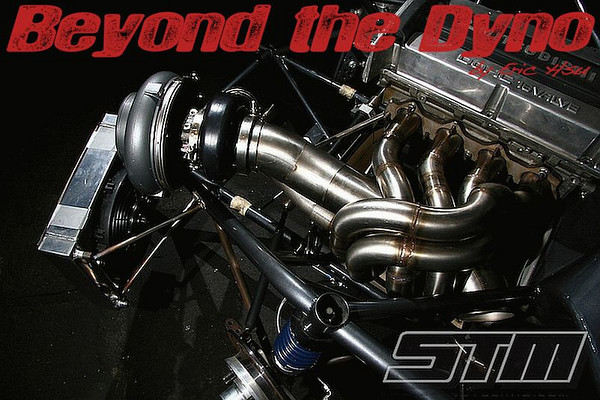

Every thing is coming together pretty good at this point. STM packaged the engine compartment very effectively.

A TiAL BOV is used to prevent compressor surge at the end of a pass. A turbo the size of a GT45 has very large wheels within it with a significant amount of inertia. For the goal of 1400+hp, the GT45 will be ran at the very edge of its compressor map at probably near 130,000rpm. Can you visualize the picture? Big heavy wheels + 130krpm + shut throtte = potential for parts to break. A TiAL BOV is just the tool to prevent premature failures.

A TiAL MV-S wastegate is used on the hot side of the charge plumbing to control boost during staging and launch. Here’s what Andre has to say about a wastegate on the charge side, ”The wastegate on the intercooler confuses a lot of people so i will clear that up. We still use a conventional exhaust mounted wastegate for actual boost control down the track. The wastegate on the intercooler is used to provide stable boost during staging. By selecting the correct spring we can very accurately control the boost while on the 2 step launch control and this means that if someone hangs you out to dry on the lights your boost won’t budge. Having absolutely repeatable boost and rpm on the line is critical in getting repeatable launches out of these cars.” I guess people play staging games on the other side of the world too.

Here’s the completed methanol and intercooler water tank.

It’s all kind of tight isn’t it? This was all necessary to keep the EVO’s original body lines. It also took a lot of planning, design, and thought from the guys at STM. The water pump is located inside of the water tank to keep the installation even cleaner. What I like about it all is that everything is extremely well packaged and is still easily accessed for service.