,

|

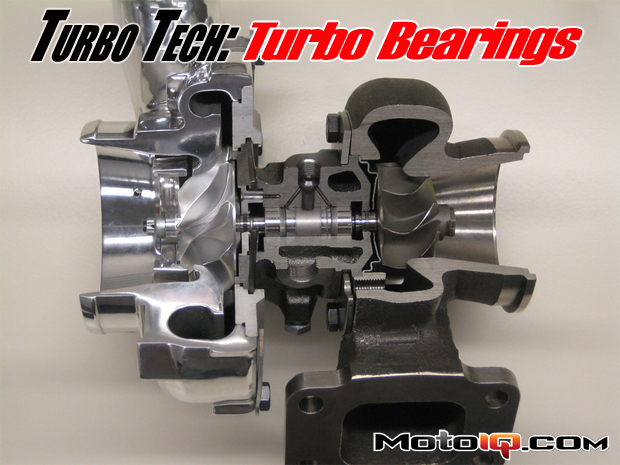

This is a diagram showing Couette flow (with a bunch of assumptions); it’s the flow pattern of a fluid between two infinite plates under laminar flow conditions. The flow between the thrust bearing and thrust collar can be represented by Couette flow when the flow is laminar. You can see how the fluid is sheared creating shear stress as one plate moves relative to another. |

Remember that thrust bearing with 45 lbs of weight on it? The film of oil on the thrust bearing has to support all the load while the shaft spins a couple hundred thousand rpms and that eats up a lot of power. In fact, the thrust bearing alone can eat up over 1000 watts of power. To put that in perspective, your average person who works out regularly can probably maintain about 100W for a few hours on a stationary bike. An amateur cyclist can maintain around 150-200W. A pro-cyclist can only do 1000W in an all-out sprint. FYI, there are 746 watts in one horsepower. Needless to say, the thrust bearing soaks up a lot of power and all that power ends up as heat added to the oil.

|

Taylor-Couette flow is specifically for the flow pattern of a fluid between two cylinders where one cylinder is spinnng relative to the other. This represents the flow between the journal bearings and shaft. In this series of photos, the low Reynolds (Re) number shows laminar flow. As the Re number gets higher, you get turbulent and unstable flow. In the case of Taylor-Couette flow, you get these Taylor vortices. If you want to know more, google it. |

Ball bearings require less oil to operate because they do not work on the hydrodynamic film principle. As there is less oil, there is less shearing of oil and also less oil to fling around resulting in greatly reduced power loss. Less power loss in the bearings means more power to spin the compressor resulting in faster spool-up and transient response.

|

This chart shows the transient response advantage of a ball bearing over a journal (sleeve) bearing. The ball bearing turbo goes from ~24,000 rpms to 120,000 rpms about 0.4 seconds faster than the journal bearing turbo. In this case, the ball bearing turbo spools up in 75% of the time of the journal bearing turbo. |

In a performance application, you can see why ball bearings are superior. In the real world, journal bearings are cheap and they do the job. Car manufacturers like cheap. Also, ball bearings are relatively noisy as compared to journal bearings; remember, there is no contacting of parts in a journal bearing system while ball bearings have all the balls spinning around while in contact with the inner and outer races. Car manufacturers like quiet. However, the conditions are changing making the ball bearing look more attractive. Engine manufacturers are using lower and lower viscosity oils in order to increase their fuel mileage. Really thin oil is not really a good thing for journal bearings and supporting loads. Also, car makers want the best transient response possible and cold thick oil makes for a slow responding journal bearing. The high performance Nissans of the 1990s used ball bearing Garrett turbos, so maybe we’ll see ball bearing turbos again in the near future on cars straight from the manufacturers.

SOURCES