The serial plate of the engine now looks fantastic.

The front face of the block cleaned up nicely

The intake runners of the head turned out great.

The steel hood latch went from old and rusty to better than new.

Additional Vapor Blasted Parts:

These vintage Lotus valve covers cleaned up nicely.

This water line turned out equally as nice

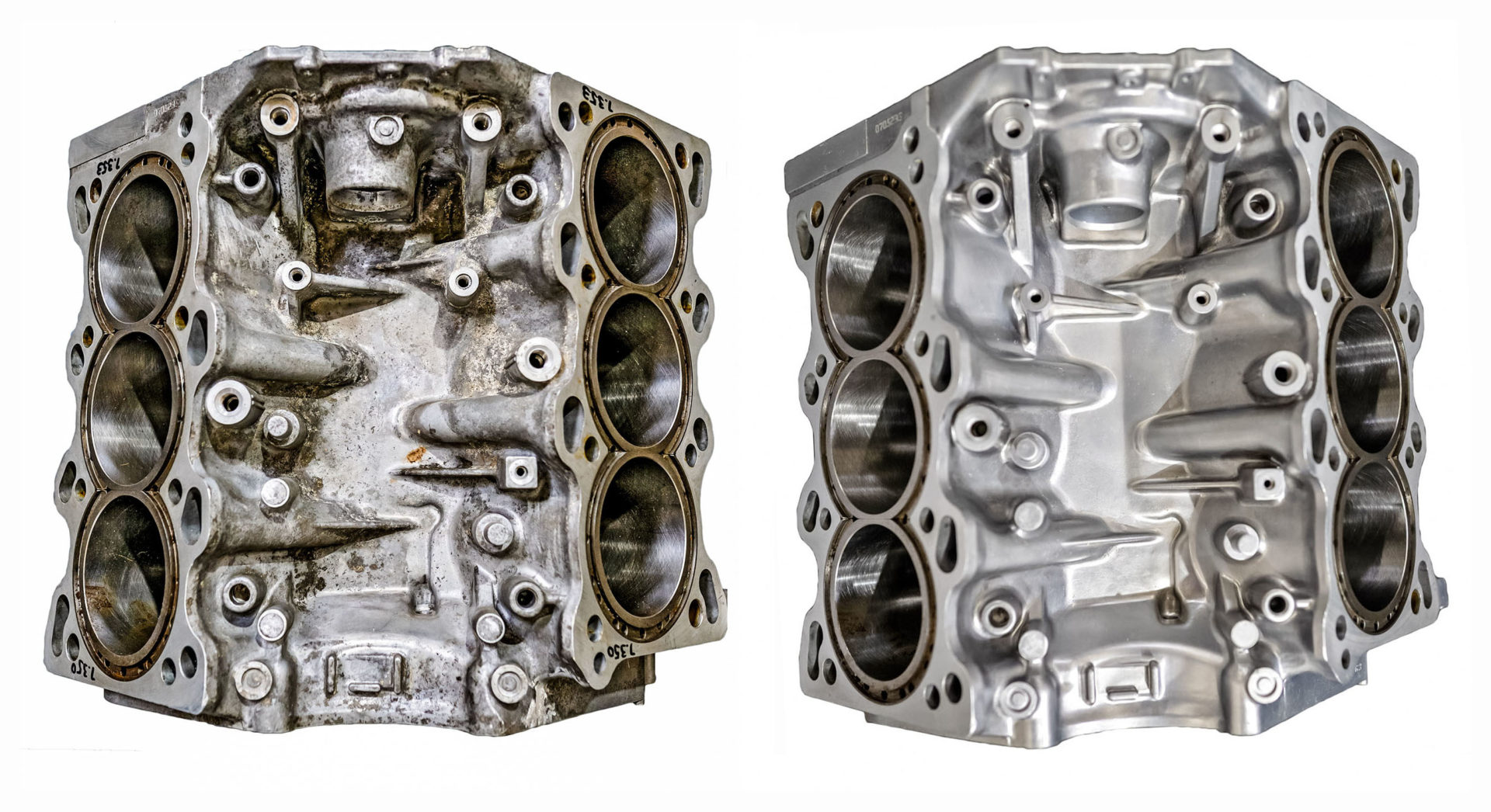

Sand casted blocks have a much rougher finish than the diecast block in the NSX. But they turn out just as clean and really expose the nuances of each grain of sand in the casting

Sand casted blocks have a much rougher finish than the diecast block in the NSX. But they turn out just as clean and really expose the nuances of each grain of sand in the casting

18 comments

Love doing this at home with a bag of baking soda and a pressure washer!

How well does that work? Can it remove heavy corrosion and baked on carbon? Does a pressure washer develop enough pressure? Doesn’t the baking soda dissolve? I also believe that wet soda blasting does not leave the beautiful surface finish. I am pretty sure simply putting baking soda in a pressure washer isnt going to give you anywhere near these results.

Baking soda works well, but not mixed with water. I use a siphon gun for soda blasting but it must be dry

After further research I found that baking soda can be used wet, but I’m not sure I’d want to run anything like that through my pressure washer.

I saw on youtube that soda blasting does not leave anywhere near as nice of a finish and doesnt appear to clean as well either. Looks like it takes a lot longer too.

Dry soda blasting is one of the least effective methods at removing tough surface contaminates. It’s mostly for cleaning. The big advantage of wet blasting is the ‘cushioning’ of the impact of the media. Since that’s not really a problem to begin with for soda blasting, and due to soda’s effect when mixed with water, it’s not exactly the same benefit as wet blasting harder media like glass and sand.

How does it compare to sand blasting with respect to removal of all media after processing? A piece of sand in an oil gallery can be catastrophic!

Of course you have to clean the block carefully like you would in any good engine build.

I don’t blast major engine parts because it’s just too hard to clean everything, and even then there is no way to check. My local machine shop has a water based, heated cleaning cabinet that really works well.

A company I worked for 50 years ago had a vapor blaster, it’s not a new tech.

Many machine shops nowdays for iron blocks uses baking and shot peening instead of hot tanking. Also for aluminum, wash cabinet and walnut blasting. You always have to remove all galley plugs and brush them out, not just spray them out. Its SOP when building engines. We never have problems. You also mask everything off before blasting. SOP. Wet blasting has been around for awhile but these newer machines with different types of media that give such nice surface finishes are new to our industry.

I like the shiny finish this leaves on the surface. Makes me wonder how this will do on steel.

Great article featuring our customers! If you would like to know more about vapor blasting, visit our website: https://www.vaporblastingequipment.com/ they use our Aquablast 1215.

Is this what was used in project binky when they cleaned the transmission p parts?

Yes, yes it was.

Would you apply a top coat to keep oxidation from setting in? Its now raw alum and would oxidize quickly.

It doesn’t oxidize nearly as quickly as a dry blasted part because of there being less surface contaminants and the surface less porous, but yeah it would still need a coating of some type if you want it to stay looking like this long term. Expect it to be about the same as bare polished metal.

1. I’m curious as to why some machined surfaces need to be taped and others not? There are a lot of gasket, bearing, and seal surfaces being blasted here, but not the deck surface for the head.

2. What kind of post vapor blasting cleaning needs to be done? Does the wet media need to be rinsed out? Is that part of the service Mountune offers? Or do you have to use hot, soapy water and brushes, after?

3. Are the internals of engine cases and various galleys every blasted? E.g., to remove the various hues of baked on engine oil.

4. There are quite a few different alternative names mentioned for this process. Aside from using Mountune’s services how would I know someone else is using the same process even if they use a different name?

Awesome results. What size glass bead is used and at what pressure air ?