,

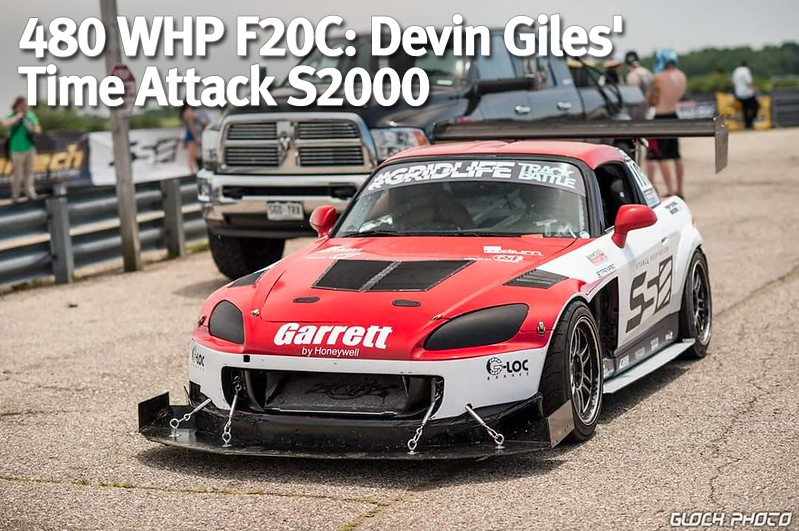

Air going in the front bumper opening must have a good path to flow out. Trackspec hood louvers provide the exit path for the air which improves cooling and reduces front-end lift.

Air going in the front bumper opening must have a good path to flow out. Trackspec hood louvers provide the exit path for the air which improves cooling and reduces front-end lift.

Trackspec fender louvers help relieve pressure build-up in the wheel wells, reducing front-end lift.

Trackspec fender louvers help relieve pressure build-up in the wheel wells, reducing front-end lift.

The fenders were hacked to allow air to exit the wheel well. The side splitters were built under the advisement of Professional Awesome, too.

The fenders were hacked to allow air to exit the wheel well. The side splitters were built under the advisement of Professional Awesome, too.

A Honeywell Garrett GTX3582R Gen 2 turbo with Garrett v-band turbine housing provides the boost to a stock F20C engine. A DOC Race equal-length manifold connect the two. The oil cooler is mounted behind the intercooler where the air coming off the intercooler is still plenty cool relative to the oil temperature based on our own testing of an oil cooler mounted behind the radiator.

A Honeywell Garrett GTX3582R Gen 2 turbo with Garrett v-band turbine housing provides the boost to a stock F20C engine. A DOC Race equal-length manifold connect the two. The oil cooler is mounted behind the intercooler where the air coming off the intercooler is still plenty cool relative to the oil temperature based on our own testing of an oil cooler mounted behind the radiator. I’d guesstimate for Devin’s car that the air coming out of the turbo is about 100F hotter than ambient, so figure it’s about the same as coolant temp. So I’d guess the air coming off the IC is around 120F assuming the ambient air temp is around 70F which means the air is plenty cool for going through the oil cooler. The IC pipe between the IC and intake manifold is wrapped in gold reflective tape to try to keep the charge air as cool as possible after it has been cooled down by the IC. Notice all the heat wrapping and heat shielding of everything around the turbo and downpipe. A race car can’t finish if it catches parts on fire or melts them. Turbosmart components handle the wastegate and BOV duties.

As you MIQ readers know, cold air is better for turbos and this black accordion tube is fitted to bring cold air from the front of the car to the turbo inlet. The turbo setup made 480whp using 14psi of boost on a Mustang dyno with E85 fuel before reaching the limit of the injectors. Getting the power from the engine to the transmission is an ACT HD clutch and disk setup bolted to a Competition Clutch ultralight flywheel. So, the power level is probably close to the limit of the clutch too.

As you MIQ readers know, cold air is better for turbos and this black accordion tube is fitted to bring cold air from the front of the car to the turbo inlet. The turbo setup made 480whp using 14psi of boost on a Mustang dyno with E85 fuel before reaching the limit of the injectors. Getting the power from the engine to the transmission is an ACT HD clutch and disk setup bolted to a Competition Clutch ultralight flywheel. So, the power level is probably close to the limit of the clutch too.