Project S2000: Part 21 – Getting Rid of Squish

Khiem Dinh is an engineer for Honeywell Turbo Technologies at the time of this writing. All statements and opinions expressed by Khiem Dinh are solely those of Khiem Dinh and not reflective of Honeywell Turbo Technologies.

I’m often of the philosophy of replacing things as they wear out. And when they wear out, I might as well upgrade! It all started with a slight banging noise while going over bumps. Over a bit of time, it got progressively worse. Eventually, going over any type of bump including creeping over speed bumps caused a loud banging noise. What was the source?

I took a few steps in diagnosing the issue. The banging noise while going over bumps would disappear if I held brake pressure. Therefore, the torque applied by the brakes was holding whatever that was loose in place while going over the bump. In researching possible issues, it seems bad tie-rods and sway bar end links were possible culprits. I checked the tie-rods and could not determine any free play in the joints. I disconnected the sway bar and drove around but the banging noise still remained. I checked everything in the brake system to make sure there was nothing loose. Yet the noise remained. So what was left that could cause the noise?

Control arm bushings were what I narrowed it down to. The noise only came from the left side of the car. With the wheels off, I banged on the brake caliper on each side of the car with my hand. Banging on the right side resulted in no noise. Banging on the left side did result in little bit of noise. Why bang on the brake caliper? The caliper is solidly mounted to the spindle which is connected to the control arm. So the force I applied to the caliper gets sent all the way through the control arm. In addition to the noise getting worse, the steering was getting progressively unstable during hard cornering. While cornering at relatively high lateral G’s mid-corner, the car was not tracking true. Instead, the front-end felt unstable and would not hold a clean line. So this issue also pointed to the control arm bushings being the issue. The handling malady did not noticeably manifest itself until the banging noise had gotten severe. It should not be a surprise the stock bushings have worn out after the hard use I’ve put them through along with the additional loading from the high grip Nitto NT01s.

Here’s the front lower control arm in its rusty cast iron glory.

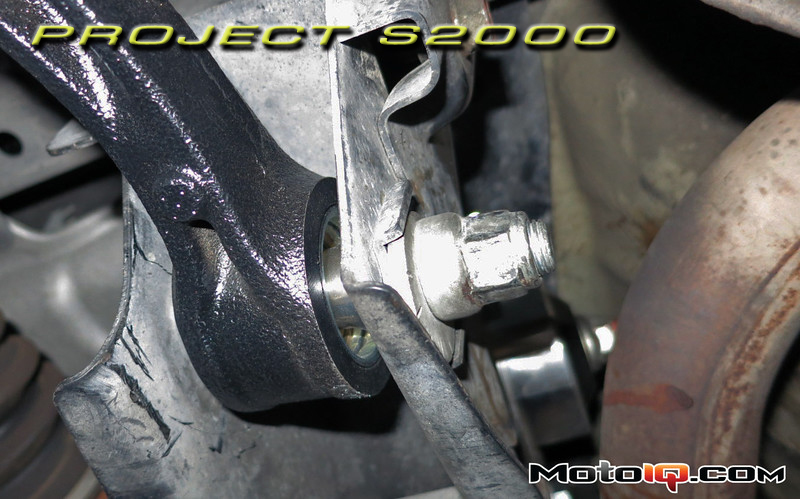

Here’s the front lower control arm in its rusty cast iron glory. This is the big bushing at the end of the front lower control arm. There are huge voids in the rubber between the control arm and the metal sleeve in the middle. Look closely at the 4 o’clock position, and you can see the white background peeping through indicating this bushing was torn and worn.

This is the big bushing at the end of the front lower control arm. There are huge voids in the rubber between the control arm and the metal sleeve in the middle. Look closely at the 4 o’clock position, and you can see the white background peeping through indicating this bushing was torn and worn.

On the left are the upper wishbone control arms with the SPC adjustable ball joints. On the right is a rear upper arm. All of the arms are shown in their rusty used form.

On the left are the upper wishbone control arms with the SPC adjustable ball joints. On the right is a rear upper arm. All of the arms are shown in their rusty used form. A close-up of one of the bushings on the rear upper arm shows some of the wear on the components.

A close-up of one of the bushings on the rear upper arm shows some of the wear on the components.