,

The piston pin is slid into place. With WPC treatment, everything goes together super easily.

The piston pin locks are wound into place.

Howard winds the piston rings into place on the JE pistons.

The rod bearings are installed and coated with assembly lube.

Next Howard oils up the cylinder walls of the block. This will give the pistons and rings some initial start-up lubrication.

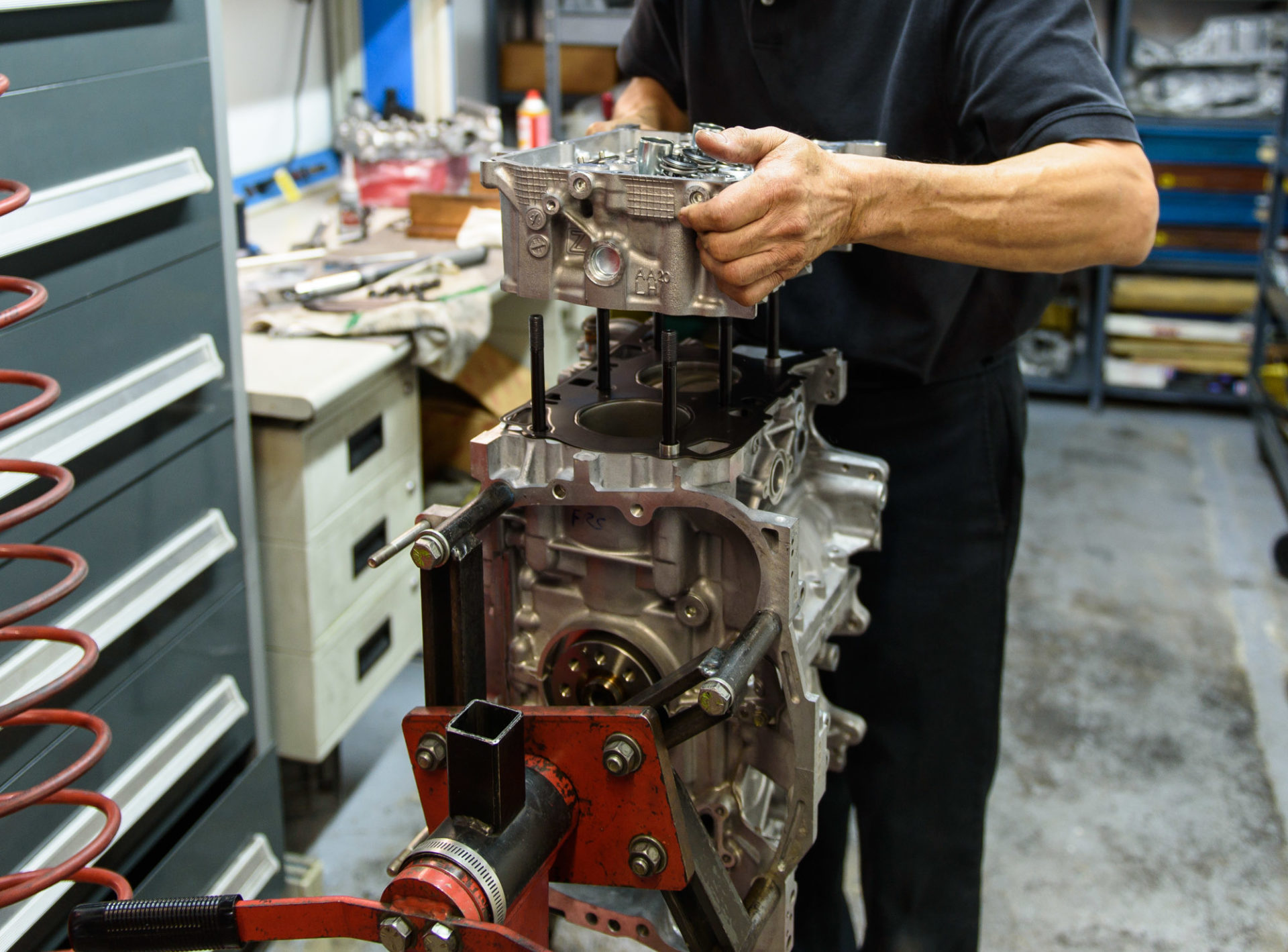

Using a ring compressor, the pistons are slid into the bore.

4 comments

Man, the FA is just not a power motor.

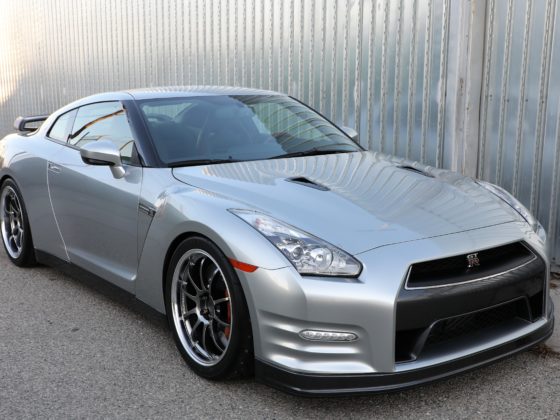

Not the Subaru, but just wanted to drop a line congratulating Michele on her GT-1 podium at the runoffs.

I’m curious why the pistons were coated after wpc treatment. Wouldn’t the tiny dimples caused by wpc be smoothed out or removed by the coating building up? Was wpc just for strength benefits? I’m also confused because I thought I’d read wpc treatment could be done to coated surfaces. Did they mean something harder like chrome?

Thanks in advance for any reply

I was using the WPC for ring groove freeness and longevity and to reduce the galling of the piston up there. WPC can be done to stuff like nitriding and hard chrome but it will remove organic coatings.