,

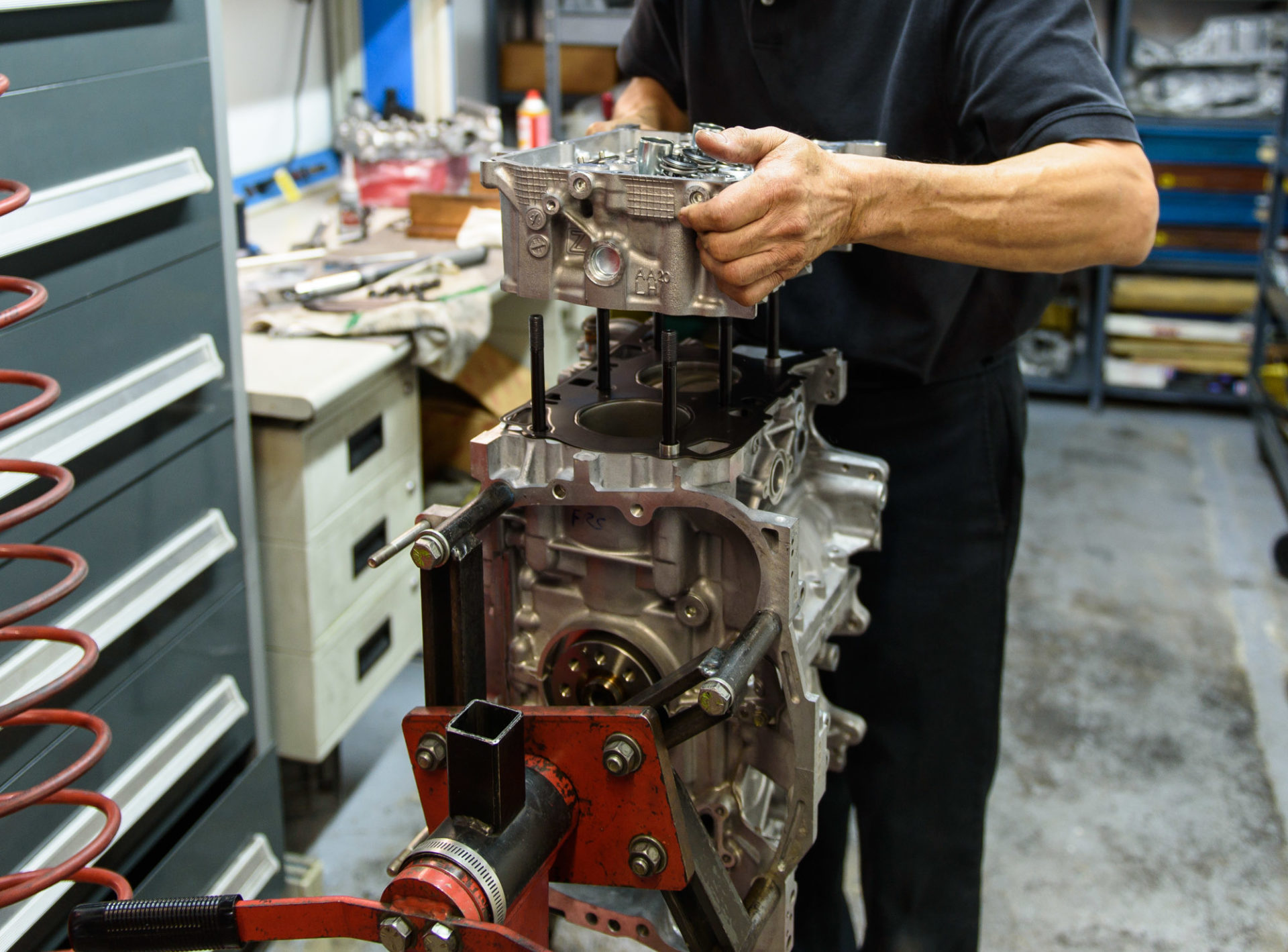

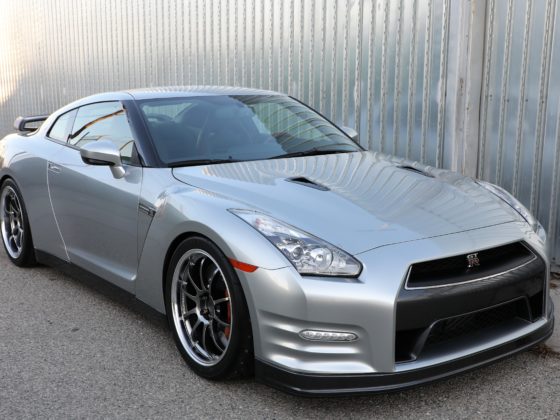

After assembly, Michele and team installed the engine into her car. Michele runs an Edelbrock supercharger in her car, and we were all very eager to see what the new engine would do.

Michele took her car to Delicious Tuning to get the ECU all dialed in for the new engine. With lower compression, a smaller supercharger pulley was used for 3 more pounds of boost than the base Edelbrock kit.

The engine’s powerband is linear and very wide with more power off of idle as the stock FA20 engine makes going full tilt! The green trace on the dyno sheet is the stock engine without the supercharger, of course.

Our story does not have a happy ending though. Even with all of our care in assembly and a conservative tune, our beautiful engine spun a rod bearing and threw a rod just a few laps into its first track test.

Our initial look into what happened points to a broken oil pump gear causing catastrophic lubrication failure. Some road racing FA20 engines have shown evidence of oil pump distress before, and the FA is starting to develop a reputation for not feeding the bearings well with its non-priority main oil galley.

We will be working to fix some of these issues and build Michele an engine with an oiling system that can withstand high revs at high power levels for extended periods of time in our next installment of our FA20 engine build. Stay tuned.

Read Part One!

SOURCES

JE Pistons

King Bearings

Supertech Performance

WPC Treatment

ARP

CP Carillo

Piper Cams USA

SwainTech Coatings

4 comments

Man, the FA is just not a power motor.

Not the Subaru, but just wanted to drop a line congratulating Michele on her GT-1 podium at the runoffs.

I’m curious why the pistons were coated after wpc treatment. Wouldn’t the tiny dimples caused by wpc be smoothed out or removed by the coating building up? Was wpc just for strength benefits? I’m also confused because I thought I’d read wpc treatment could be done to coated surfaces. Did they mean something harder like chrome?

Thanks in advance for any reply

I was using the WPC for ring groove freeness and longevity and to reduce the galling of the piston up there. WPC can be done to stuff like nitriding and hard chrome but it will remove organic coatings.