,

I know that you are probably reading this and saying “wow this is just a Radium ad”, or “why is this jackass so excited over a freakin' catch can”… Well don't take my word for it, see for yourself.

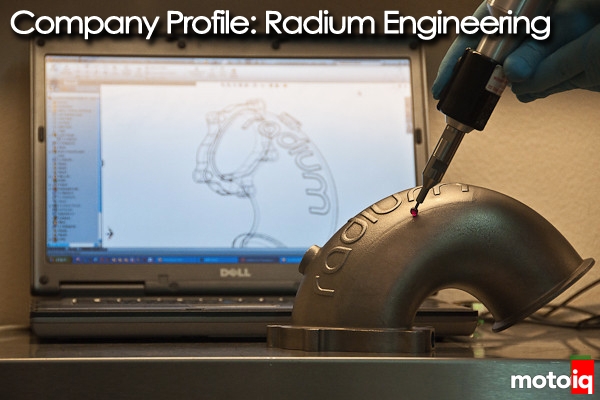

Another well engineered work of art. And when I use the word engineered I mean that literally. JP and Aaron from Radium are bona fide engineer's using all of the necessary experience and modern technology to produce the best quality parts. For the catch can design you can clearly see it was meant to function properly, not just look pretty. The incoming oily air enters in to the first chamber where it is pushed through stainless mesh condensers. The mesh is designed to help trap oil particles by creating a phase change that allows the liquid to drip in to the bottom of the catch can.

|

|

| The stainless mesh and the purpose they serve. Radium sends plenty! |

A unique feature is that the stainless mesh condensers are provided by Radium and are removable for cleaning and servicing. You can add as few or as many as you like to adjust the filtering they provide for your application. Once they have passed through this chamber the recirculation port is located up high in the in the can using gravity to further remove oil from the air stream by letting it settle to the bottom. The cleaned air then passes out and can be routed back in to the intake stream.The collected oil can then be drained from the catch can by removing the bottom half or by using the optional petcock drain system that Radium offers. In certain vehicles you can re-route the oil back in to the appropriate location.

|

| The two piece design unscrews easily for quick drainage and the baller status dipstick speaks for itself Jimmy. |

|

| Radium also offers an optional petcock system. |