Stick the valves in place in the head and smear a thin layer of grease on the deck around the combustion chamber.

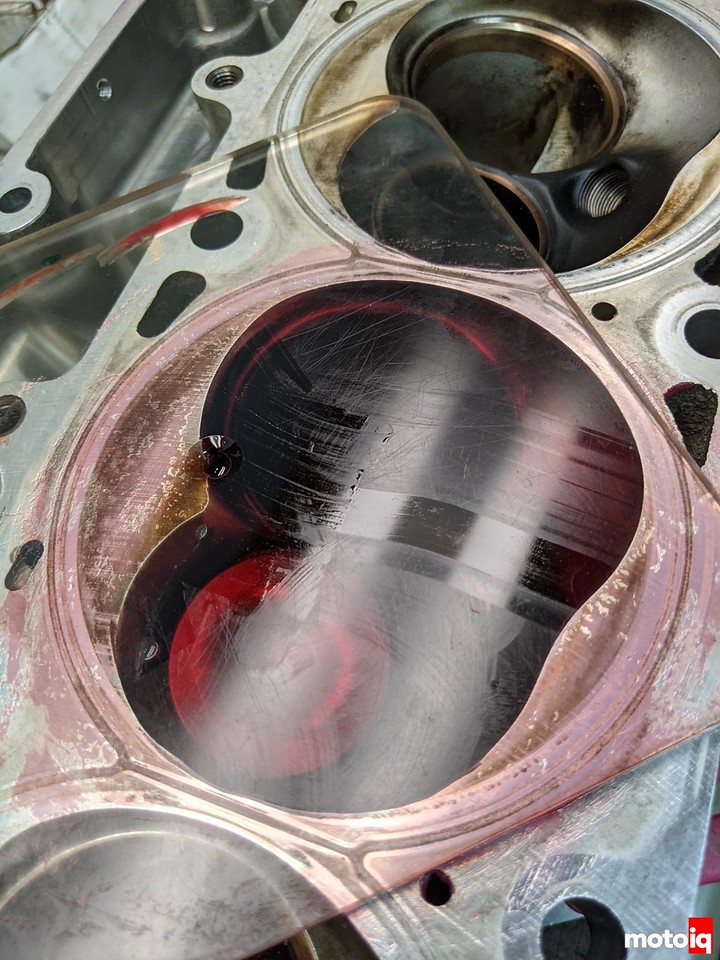

This is what your sealing grease job will look like. Note the thin layers.

Make a lexan or plexiglass plate with a small countersunk hole in the middle.

1 comment

Very creative Mike ! I borrowed a 50 ml burette from work for this, and double checked one of the 6 chambers to verify consistency. My old GT6 had flat top pistons with a variation on distance from deck height to top of pistons. To compensate for this each head chamber had different volumes, so when bolted up, the total volumes were identical.

I also borrowed a triple-beam balance for matching piston weights. Other balancing was done by a trusted machine shop.