,

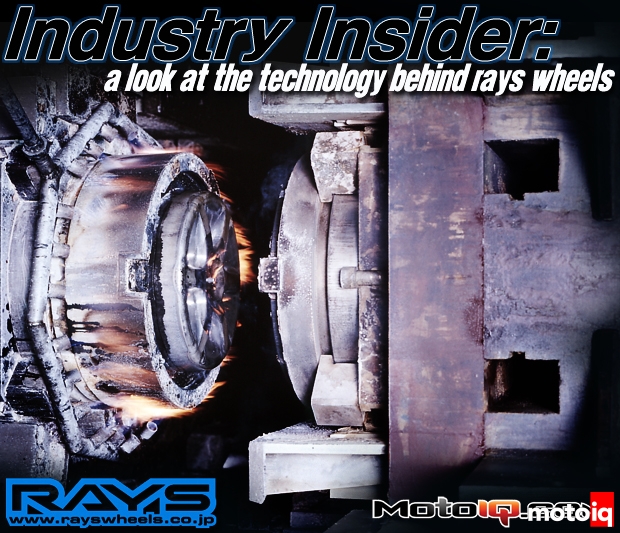

The multistage forging gives the part's internal grain an almost organic arrangement that resists fatigue and gives the greatest amount of strength, Hence the name 3D forging. The near net shape created by the multistage forging process also creates a wheel that is much truer and much closer to balance than simply machine facing off an irregularly shaped forged blank created in one step.

The finished blank is then solution heat treated and artificially age treated to harden the metal optimally and give it the best strength possible. Aluminum has an unusual property where it gains strength as it sits. Artificial aging is part of the heat treating process that accelerates this age hardening so the finished wheel will be at full strength when brand new. The blank is now fully formed and recognizable as a Volk wheel.

|

Secondary forging processes create other features in the now recognizable TE37 wheels. |

Next a CNC machining center that is dimensionally accurate to within one thousandth of a mm faces off the mounting pad, finishes off the nut seats, makes the hole for the valve stem and touches up the center bore. If a wheel needs a diamond cut shiny lip or other similar features, it is created now. Due to the precise forging methods, almost no final machining is needed; this creates a wheel with really good balance. As a last step the wheels are shotpeened. The shotpeening process consists of blasting the part with small steel balls at high velocities. It imparts compressive stress on the surface of the part which helps prevent cracks from forming on the surface that could propagate into a bigger crack causing failure. To ensure that there are no hidden flaws in the metal, the wheel is subjected to non destructive testing with an Eddy Current tester.

|

A CNC machine finalizes the center bore and the lug seat area. |

The almost completed wheel is now given its final finish which could be anodizing or a multistage paint process. This consists of a zirconium process / chromate surface treatment for adhesion and corrosion resistance followed by a 4 coat, 4 bake paint process consisting of powder primer, two layers of liquid paint for color and a final layer of clear. Wheels intended for racing or the tuner markets tend to be anodized and wheels that must meet OEM corrosion standards are painted.

Chuck Johnson's Land Speed Racing Sentra.

Chuck Johnson's Land Speed Racing Sentra.