,

|

| The exhaust manifold looks to be double-walled stainless steel with the turbine housing welded to it. The compressor housing has an integrated compressor bypass valve. This turbo uses an electric wastegate actuator instead of a more old-school pressure actuator. Of course, directly after the turbo is a close-coupled catalytic converter. As for the red and black wires, don’t mind those, they are just for powering the electronics of the car on the show flow. |

| ||

| The key to reliability is controlling the heat. The intercooler is down in the middle with the radiator and A/C condenser getting unobstructed cool air above the intercooler. Getting clean cool air to the radiator is important! Also, in the two openings on either side of the intercooler are more heat exchangers. At least one, if not both, are oil coolers. One other observation, peeking out from behind the trademark BMW kidney grills looks to be two braces used to stiffen up the front end somehow. |

|

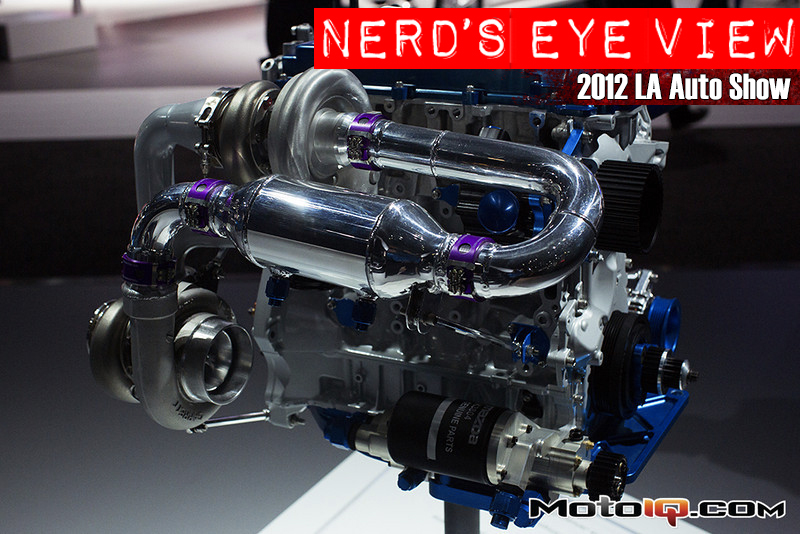

| The M5 has been out for a year now, but it’s still cool to check out. It’s a twin-turbo 4.4L V8 which is basically two 2.2L 4-cylinders joined together. There is two of everything: air boxes, air-to-water intercoolers, turbos from Honeywell Turbo Technologies, you get the idea. The relatively unique feature for a gasoline turbocharged engine is having the exhaust manifolds and turbos mounted in the V of the engine up top. The layout makes a whole lot of sense when looking at this picture. Well, the first thing that you can NOT see which is highly important is that both turbos are twin-scroll. Due to the firing order of a V8, to pair up the cylinders to the turbos correctly requires each turbo to get exhaust from both exhaust banks. Placing the turbos in the middle of the V along with the exhaust manifolds allows this to happen. I’ve shown the torque curve of this engine before here and it’s flat, wide, and comes on very early. Now we can talk about the advantages of this packaging layout that we can see. The distance from the air box to the turbo is short reducing pressure loss which increases power. The path of the air from the turbo outlet to air-to-water intercooler to intake manifold is very short. A short airflow path reduces pressure drop and air volume which improves power and throttle response. I bet the total length from the air filter to the intake manifold for both sides of the engine is shorter than a Subaru STI using a front mount IC and standard intake manifold configuration (not a reversed intake manifold). |

|

| Again, packaging can get difficult so the engineers have to get creative. They did not want the oil cooler in the way of cool air getting to the radiator, so they mounted the oil cooler horizontal. Now both the oil cooler and radiator get cold air. The air going through the oil cooler is dumped under the car. |

|

| This is the 2.0L diesel from VW/Audi (VAG). It looks to use a single VNT turbo with the exhaust first dumping into a SCR catalyst to reduce NOx. From there, the exhaust makes a 180 degree turn into a diesel particulate filter (DPF). The exhaust has two flow paths now: out the muffler or through what looks like an EGR (exhaust gas recirculation) cooler. It looks similar to the oil cooler donuts that oil filters attach to in that this also is donut shaped and appears to use coolant to cool off the recirculated exhaust gas. After the EGR cooler, the cooled exhaust gas is recirculated back to the compressor inlet. EGR is used to reduce NOx of course. |