,

The next step is to measure the valve lash. On a Nissan VQ engine the lash is set by select fit lifters which are available from Nissan in many different thicknesses. This is the reason why you don't want to mix these up when you change the valve springs. JWT cams are ground on the stock base circle diameter so normally most of your lifters will be okay but you must check them. On our high mileage engine, two valves had slightly tight clearance when we checked. This is to be expected due to valve face and seat wear.

The next step is to measure the valve lash. On a Nissan VQ engine the lash is set by select fit lifters which are available from Nissan in many different thicknesses. This is the reason why you don't want to mix these up when you change the valve springs. JWT cams are ground on the stock base circle diameter so normally most of your lifters will be okay but you must check them. On our high mileage engine, two valves had slightly tight clearance when we checked. This is to be expected due to valve face and seat wear. So we needed to remove the cam to change the lifter with a thinner one to get more clearance. Too tight clearance can result in burnt valves so this should be addressed. Many crappy shops skip this step altogether since it is tedious and requires running around and ordering stuff from Nissan, hence there are some botched VQ's after cam changes out there.

So we needed to remove the cam to change the lifter with a thinner one to get more clearance. Too tight clearance can result in burnt valves so this should be addressed. Many crappy shops skip this step altogether since it is tedious and requires running around and ordering stuff from Nissan, hence there are some botched VQ's after cam changes out there. Fortunately Howard Watanabe of Technosquare and MotoIQ's ace wrench has a lot of VQ lifters in stock as he builds these engines quite frequently. Howard removes the old lifter with a magnet and drops new lifters in. The cam then has to be reinstalled and retorqued with the lash then re checked.

Fortunately Howard Watanabe of Technosquare and MotoIQ's ace wrench has a lot of VQ lifters in stock as he builds these engines quite frequently. Howard removes the old lifter with a magnet and drops new lifters in. The cam then has to be reinstalled and retorqued with the lash then re checked. With the cams installed and the lash all set, it is time to start reassembling the engine.

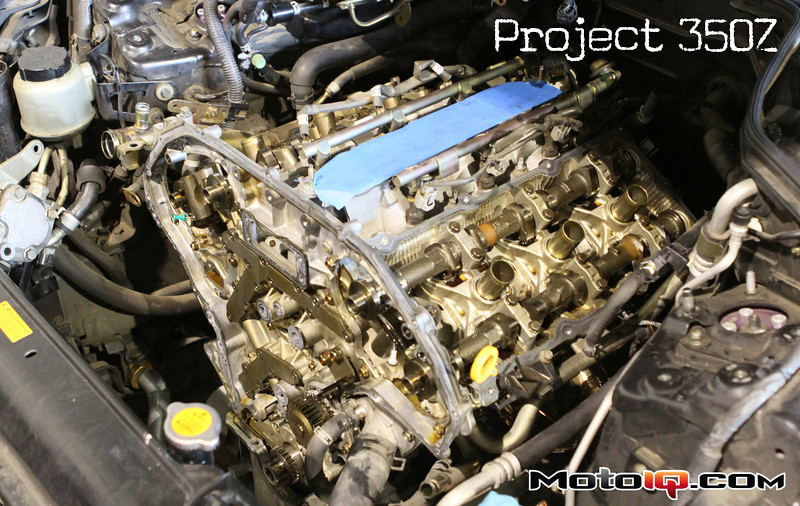

With the cams installed and the lash all set, it is time to start reassembling the engine. The valve covers are temporarily placed on top of everything to keep potential debris out while the front end drive stuff is being assembled.

The valve covers are temporarily placed on top of everything to keep potential debris out while the front end drive stuff is being assembled. On a VQ engine this is the deadly DIY triangle formed by the cams and the chain tensioners. There is a lot going on here that you can mess up if you are lame. We will try to point out the common pitfalls when putting this area back together.

On a VQ engine this is the deadly DIY triangle formed by the cams and the chain tensioners. There is a lot going on here that you can mess up if you are lame. We will try to point out the common pitfalls when putting this area back together.