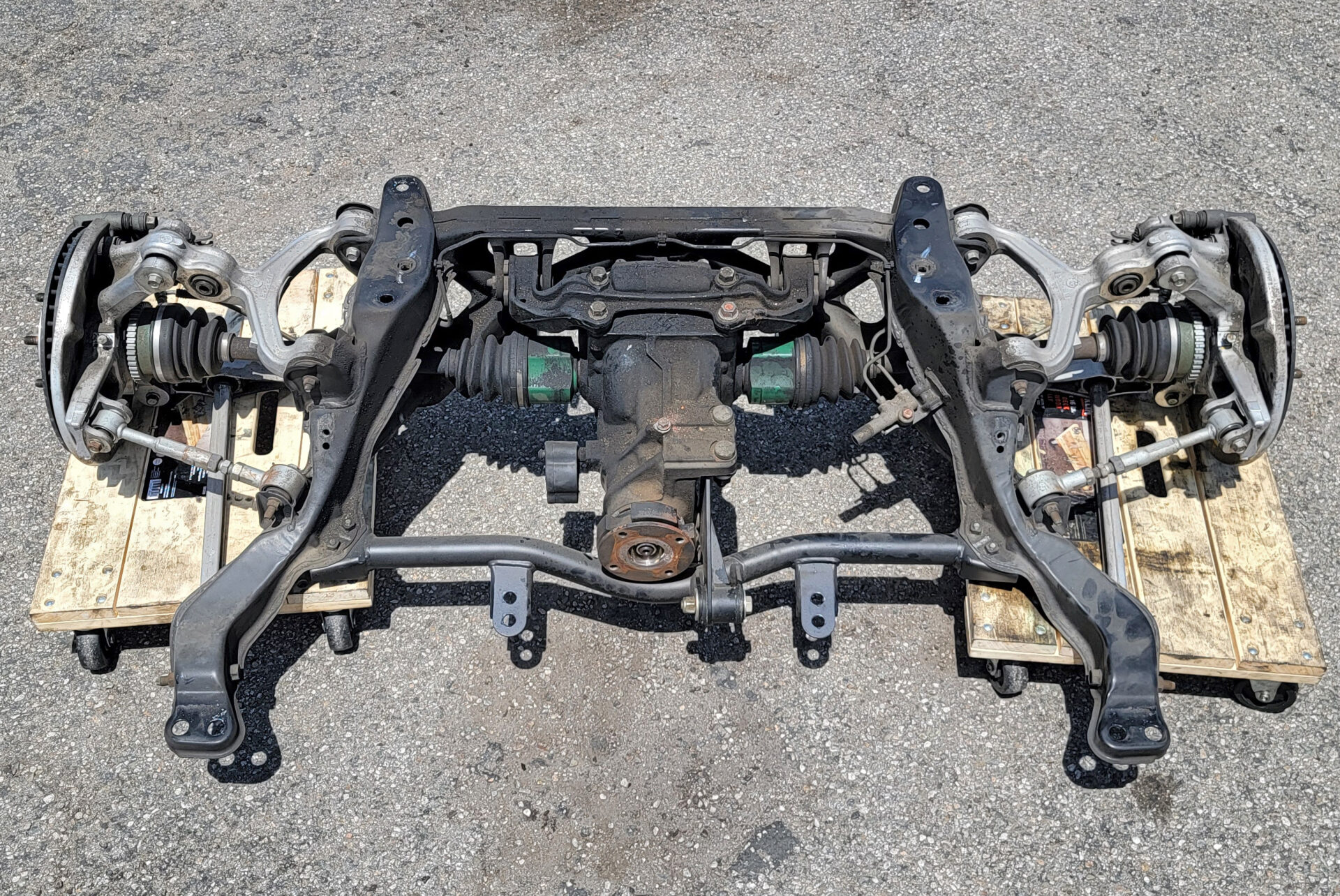

The FD RX-7 has many drivetrain limitations that start to fail as power approaches double the factory output. Upgrading to a Ford Explorer 8.8” differential actually makes a lot of sense, even financially, at a far lower power level than most RX-7 owners realize.

The FD RX-7 has many drivetrain limitations that start to fail as power approaches double the factory output. Upgrading to a Ford Explorer 8.8” differential actually makes a lot of sense, even financially, at a far lower power level than most RX-7 owners realize.

Upgrading the FD RX-7’s fragile cast iron differential to an Aluminum Ford Explorer 8.8” diff is not just for high horsepower builds. It becomes the obvious solution when you:

-Consider installing an expensive clutch-type LSD.

-Make more than 550whp.

-Make more than 450whp and push the car.

-Drag racing or drifting with over 350whp.

-Upgraded axles are needed.

-Changing the final drive ratio is needed.

As soon as you need to replace the OEM limited slip differential with an expensive aftermarket clutch-type LSD, the Ford Explorer 8.8” swap becomes the better solution. When taking into account selling the OEM components, the all-in parts cost of the 8.8” swap is nearly the same as adding a diff brace and an aftermarket LSD to the OEM differential, which will still be limited to the strength of the factory axles and weak cast iron diff housing. This is where the Ford 8.8” swap becomes a worthwhile alternative for many RX-7 owners. Once the factory axles need to be upgraded, the Ford 8.8” swap actually becomes a far less expensive option and a no-brainer.

There are many reasons to go with the Ford Explorer 8.8” differential. The entire swap weighs LESS than stock, it is bulletproof and can handle up to 1,500whp, the aluminum differential itself is cheap and easy to find, there are a lot of inexpensive LSD options, there are tons of inexpensive gear ratios available, rebuild kits are cheap, and many shops work on them. This is the rear-end of choice for many 1,000whp+ drag race and drift platforms including: Supra, SC300, IS300, BRZ, BMWs, S14, etc…

There are many reasons to go with the Ford Explorer 8.8” differential. The entire swap weighs LESS than stock, it is bulletproof and can handle up to 1,500whp, the aluminum differential itself is cheap and easy to find, there are a lot of inexpensive LSD options, there are tons of inexpensive gear ratios available, rebuild kits are cheap, and many shops work on them. This is the rear-end of choice for many 1,000whp+ drag race and drift platforms including: Supra, SC300, IS300, BRZ, BMWs, S14, etc…

Now let’s dive deeper into the limitations of the FD RX-7’s drivetrain.

The stock Torsen limited slip differential is extremely fragile and the internal spider gears have been known to break at 300-350whp on the drag radials, but usually last upwards of 400whp on the street and road course. At roughly double the factory power output, the Torsen and Power Plant Frame (PPF) also start to fail. This is why in Part-8, we replaced the stock PPF with the Sikky Diff Brace and Banzai Transmission Crossmember. Back in the 90’s when these cars were new, the stock Torsen held up to 450whp on Hoosier tires when FD RX-7s competed in the World Challenge Series, only needing a reinforced PPF.

The stock Torsen limited slip differential is extremely fragile and the internal spider gears have been known to break at 300-350whp on the drag radials, but usually last upwards of 400whp on the street and road course. At roughly double the factory power output, the Torsen and Power Plant Frame (PPF) also start to fail. This is why in Part-8, we replaced the stock PPF with the Sikky Diff Brace and Banzai Transmission Crossmember. Back in the 90’s when these cars were new, the stock Torsen held up to 450whp on Hoosier tires when FD RX-7s competed in the World Challenge Series, only needing a reinforced PPF.

The least expensive way for the differential to handle 450-550whp was to retrofit the clutch-type LSD from the 86’-88’ Turbo II, but these are increasing in price and becoming more difficult to find. The typical solution is to buy an expensive aftermarket LSD, many of which clunk and chatter when turning and cost around the same price as the Ronin Ford Explorer 8.8” diff kit. This is the turning point where upgrading to the Ford 8.8” becomes a better option.

WHAT CAUSES FAILURES?

Torque is what breaks things, however most documented failures online reference how much horsepower a car was making, not the torque (which is generally somewhere around 75-100hp higher than the torque figure on a 13B). It is extremely difficult to determine the power and torque limit of a given component because many factors affect the point where something will fail, such as how the car is driven, if the car is drag raced, road raced, drifted, or driven on the street, the tires, drivetrain bushings, suspension bushings, play in the ball joints, bracing, clutch, shocks, wheel hop, etc…

Failures can happen from either peak stress or fatigue. Fatigue happens over time where micro-cracks grow with heat cycles and repeated stress, eventually leading to a failure. In practicality, this is all but impossible to predict The stock LSD or diff housing might be fine at a certain power level for a while, but it will break at some point whether that’s on the 2nd drag racing pass, the 20th, or in year 2. Also keep in mind that old parts are not as strong as they were when new. The FD RX-7 is now 30-year-old, so parts might now break at levels that were fine 15 years ago.

Wheel hop is a killer of components because it is a harmonic resonance between kinetic and static friction that can multiply the force by 3-times! Replacing the soft rubber motor and diff mounts with solid or high durometer bushings can reduce wheel hop, but there is a trade-off between reduced wheel hop and increasing shock and torsional strain to the diff housing from the elimination of the shock-absorbing abilities of the stock rubber bushings. Polyurethane is usually a sweet spot for NVH and control.

5 comments

Awesome update and you convinced me that upgrading the diff is the right move. This car is going to be a monster!

I love seeing all the work and choices going into this! I’m excited to see it running!

I noted in a separate video that the ronin front bridge once welded in may interfere with the existing brake lines. Appreciate any update on this as you install.

The Eaton Detroit TrueTrac is also used in both of the Project Mustangs!

https://motoiq.com/project-grey-mustang-5-0-part-5-putting-the-power-down-with-eaton/

I might note that this article applies to many other cars besides FD’s