OUR BUILD

OUR BUILD

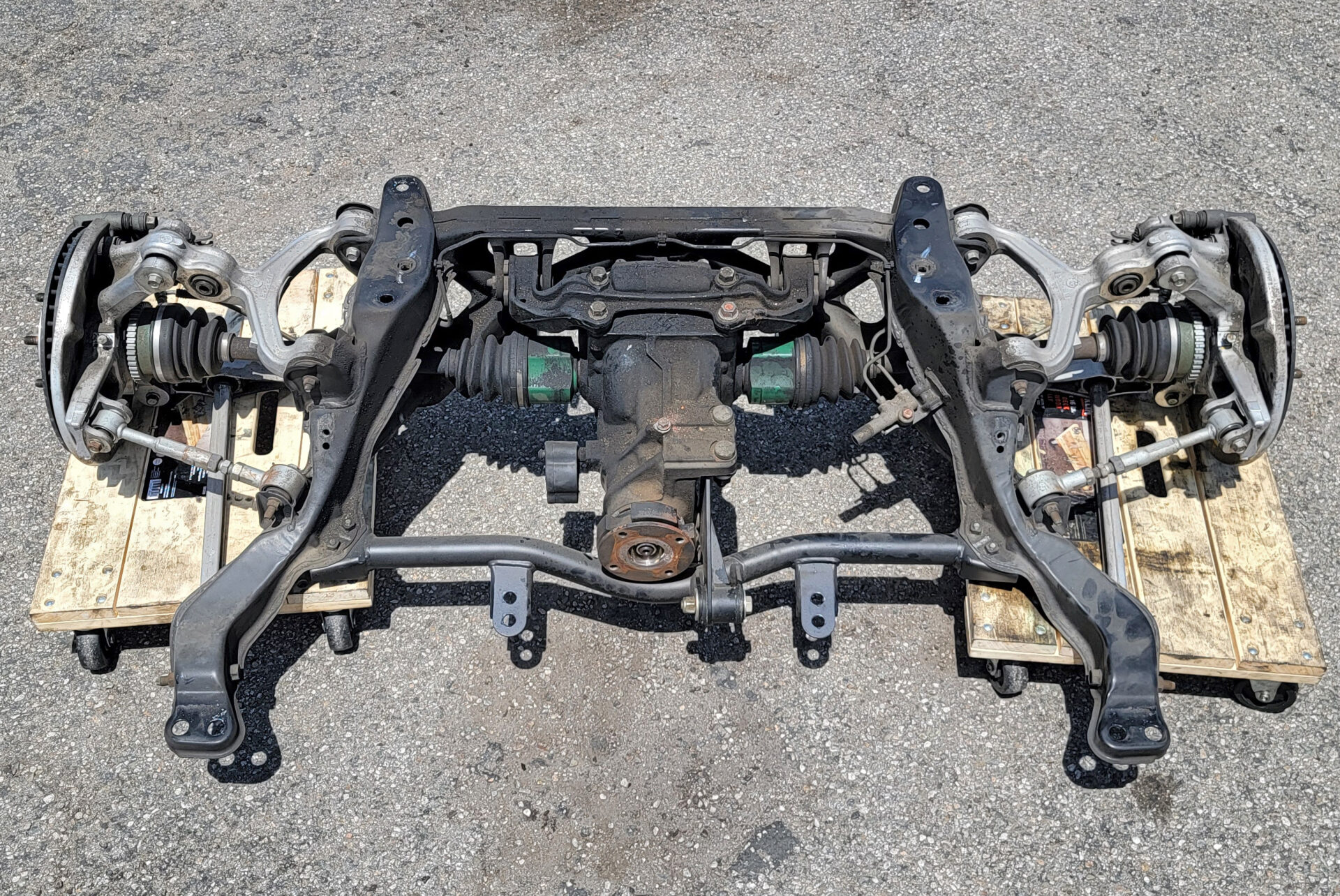

Our car is going from relatively stock to a goal of a 600whp+ that can reliably be tracked, drifted, drag-raced, and comfortable as a daily driver. This makes it an easy decision to jump straight into a Ford Explorer 8.8” differential rather than trying to make the stock differential work, only to have a borderline solution with questionable durability above 550whp.

The Ronin Ford Explorer 8.8” Standard Differential Kit is reliably capable of a far greater 600-800whp (conservatively) and consistently runs 8’s in the ¼-mile. They also offer a “Grande” upgrade kit that replaces the FD outer CVs with Explorer CVs to further improve durability and power potential to over 1,000whp.

Since the all-in parts cost of upgrading to the Ronin Explorer 8.8” differential kit costs less than keeping the OEM diff, bracing it, and upgrading to an aftermarket clutch-type LSD (after selling the OEM diff, axles, and PPF) there really is not a reason to ever upgrade the stock LSD with the OEM cast iron diff unless you are competing in an event that requires the stock drivetrain.

We decided to install the Detroit TrueTrac LSD into our Ford 8.8” housing, which is one of our all-time favorite street/track limited slip differentials. We also will be using Driveshaft Shop’s driveshaft and their entry-level bolt-in 800-1,000whp “Direct-Fit” axles that utilize the OEM wheel hubs, to make the installation more ‘bolt-in’ without having to source used Explorer CV joints. Stay tuned for the next installments to see the installation of the Ford 8.8” swap.

Least expensive way to reliably handle these power goals:

Up to 400whp – Turbo II LSD & Differential Brace.

Up to 600whp – Ronin Ford Explorer 8.8” diff kit with stock LSD.

1,000whp+ – Ronin Ford Explorer 8.8” diff kit with Ronin “Grande” or DSS “Direct-Fit” Axles.

1,400whp – Ronin Ford Explorer 8.8” diff kit and DSS “Pro-Level” Axles.

Average Power Limits of FD RX-7 Components**:

300-400whp – Stock Torsen LSD.

400whp – Power Plant Frame (PPF) and Transmission Output Shaft.

400-550whp – Stock Inner Axle Stub and Axle Bar Shaft (400tq limit).

450whp – OEM FD Iron Diff Housing.

450-550whp – Turbo II S4 (86-88) Clutch-Type LSD.

550whp – Braced/Cradled FD Iron Diff Housing (with clutch-type LSD).

600whp – Stock Axle Outer CV Joint.

600-700whp – Limit of 2003-2004 Mustang Cobra “Terminator” Aluminum Diff Housing (31-spline, diff mounting ears fail).

600-1,000whp – OEM Mazda Subframe Distorts.

800whp – OEM Wheel Hub.

800-900whp – Limit of 2002-2005 Explorer Aluminum Diff Housing (Single Ear).

800-1,000whp – Driveshaft Shop “Direct-Fit” Axles (with OEM Wheel Hubs).

800-1,100whp – OEM Subframe with Ronin Diff Mount starts to bend (requiring Ronin Subframe Supports to brace it).

900whp – Braced/Cradled FD Iron Diff Housing (with Spool and upgraded axles) – on borrowed time.

1,000whp – Braced/Cradled FD Iron Diff Housing (with Spool, upgraded axles, and a custom rear cover that retains the main caps) – on borrowed time.

1,400whp – Driveshaft Shop “Pro-Level” Axles.

1,500whp – Limit of 2007-2010 Explorer Aluminum Diff Housing (Dual Ears).

Disclaimer: The above power limitations of components are listed as horsepower and not torque because through extensive research, interviews and documentation, the vast majority of people only mention the peak horsepower output of their engine when they break something, and not torque. While torque is the force that breaks things, there is very little information online or from individual’s recollection of the torque values that components break.

Having said that, modified 13Bs tend to have relatively flat torque curves, which makes knowing the horsepower output of an engine still relevant to failures. To analyze this further, I have compiled a scatter chart of over 150 known peak horsepower and torque figures of various turbocharged 13B rotary engines in order to see a correlation between horsepower and torque. This will enable us to mathematically generalize a torque output range of known horsepower outputs when components fail.

Out of these 168 known horsepower/torque figures of various setups ranging from stock to 800hp+ builds, the average torque output is 82% of horsepower.

Out of these 168 known horsepower/torque figures of various setups ranging from stock to 800hp+ builds, the average torque output is 82% of horsepower.

– In the 325-375whp range, the average torque output is 85% of horsepower.

– In the 375-425whp range, the average torque output is 83% of horsepower.

– In the 425-475whp range, the average torque output is 79% of horsepower.

– In the 475-525whp range, the average torque output is 79% of horsepower.

– In the 525-575whp range, the average torque output is 78% of horsepower.

– Horsepower generally increases at a greater rate then torque for the 13B rotary engine

1) Quoted from this article: “When pushed aggressively at the drag strip, drifting, clutch-drops, etc… the stock drivetrain components can break around 350whp” From the data above, this happens around ~300lb-ft of torque on average.

– Drag radials, aggressive clutches, and heavy shock to the drivetrain can cause failures at relatively low power/torque figures.

2) A lot of stock FD3S drivetrain components start to break around 400whp. From the data above, this generally happens around ~332lb-ft of torque on average.

– 90% of the dyno plots in the 375-425whp range fall between 300-360lb-ft of torque.

– The dangerous outlying examples are pushing the limits of the stock twin turbos or small single turbos like the EFR7670. When pushed on E85 or alcohol injection/meth, these turbos can make up to 400lb-ft of torque (or more), greatly increasing the risk of breaking drivetrain components

3) A lot of street cars can last with around 450whp or more. From the data above, this is generally around ~355lb-ft of torque on average.

– 100% of the dyno plots in the 425-475whp range fall between 324-401lb-ft of torque.

– Street cars do not push the drivetrain or experience Wide Open Throttle (WOT) nearly as often as cars that are tracked, drifted, or raced.

– Street cars tend to spin their tires, which is easy on the drivetrain, compared to a sticky track and sticky tires that cause more shock and load to the drivetrain.

4) At 500whp and above, for cars that are not dyno queens, it becomes more common to upgrade the stock diff and trans. From the data above, this generally happens around ~397lb-ft of torque on average.

– 90% of the dyno plots in the 475-525whp range fall between 346-446lb-ft of torque

From the above chart, we have put fairly accurate torque figures to the quoted horsepower figures documented in this article. The vast majority of engine builds have torque outputs fall within a consistent range of 85% of the horsepower output of the engine.

The 400-450whp range (and mid-high 300lb-ft of torque), starts to become the risky zone for the stock FD RX-7’s drivetrain that doesn’t does more than just play around on the street.

Staying below 365whp (310lb-ft of torque) seems to be a good rule of thumb to maintain reliability of the stock trans and diff when driving the car aggressively.

VARIABLES:

Having said all of this, as I have mentioned before, there are far greater variables than just the engine’s torque output that affect the durability of the drivetrain.

– Wheel Hop is a killer, and can be a force multiplier by a factor of 3X. Avoiding wheel hop by constraining the differential or suspension arms with new or stiffer bushings is crucial for preventing the extreme damage caused by wheel hop.

– Shock from the tires (drag radials vs bias ply) can vary greatly depending on what tire is used.

– Shock from the clutch can vary greatly and many drag racers (like Len Bacon) have determined through (expensive) trial and error, which combinations of friction material, number of discs, pressure plate clamping force, etc… breaks components vs ‘cushions’ the shock load.

– Age and fatigue. Heat cycled metal in the drivetrain weakens over time and continuous use, cracks propagate and can eventually lead to a failure at a power/torque output that it has survived for weeks/months/years.

– Rotational mass

– Etc..

The durability of any component will never be determined by a fixed torque figure for the reasons above.

The power and torque limit depends on many factors such as if the car is drag raced, road raced, drifted, or driven on the street, the tires, drivetrain bushings, suspension bushings, play in the ball joints, clutch, shocks, wheel hop, etc… Most enthusiasts enjoy their cars on the street and only do brief pulls from a roll, which puts far less strain on the drivetrain. For this most common application and use, drivetrain components can last a long time at high power levels. The risk here is that doing so is a ticking time bomb and eventually something will fail, and the likelihood of something failing of they decide to do a pull from a ‘dig’, take their car to the dragstrip, or to a road course increases exponentially.

5 comments

Awesome update and you convinced me that upgrading the diff is the right move. This car is going to be a monster!

I love seeing all the work and choices going into this! I’m excited to see it running!

I noted in a separate video that the ronin front bridge once welded in may interfere with the existing brake lines. Appreciate any update on this as you install.

The Eaton Detroit TrueTrac is also used in both of the Project Mustangs!

https://motoiq.com/project-grey-mustang-5-0-part-5-putting-the-power-down-with-eaton/

I might note that this article applies to many other cars besides FD’s