With our killer engine by IAG now sitting in our shop, it was time to start gathering the peripheral components needed to support our new motor. The next thing absolutely needed for our build was a new clutch. The OEM clutch was on its last legs as we were right about at its torque capacity limit with our stock motor. If we did a two-step launch it would start slipping for a while then it would recover after the glaze wore off. Our new engine would finish it off quickly. Our clutch not only had to be able to stand up to our new gains in power but also track driving while keeping a decent pedal effort so the small woman who drives the car could easily operate it. Smoothness in operation was important as well. At the strong recommendation of the guys at IAG, we investigated the twin-disk offering from XClutch as they have had excellent luck with this unit.

We obtained XClutches 9″ organic twin-disc clutch kit for our evaluation, this kit is something XClutch has spent years developing and working toward based on customer feedback. Previously, if you had a high horsepower WRX/ STI that was street driven you would have to live with a high pedal effort, chattering ceramic clutch that would not be comfortable to drive for you and your passengers in traffic. XClutch has worked hard to develop a sprung organic solution for high HP AWD vehicles so that they can be street driven easily, hold great horsepower and torque and give an excellent service life in doing so.

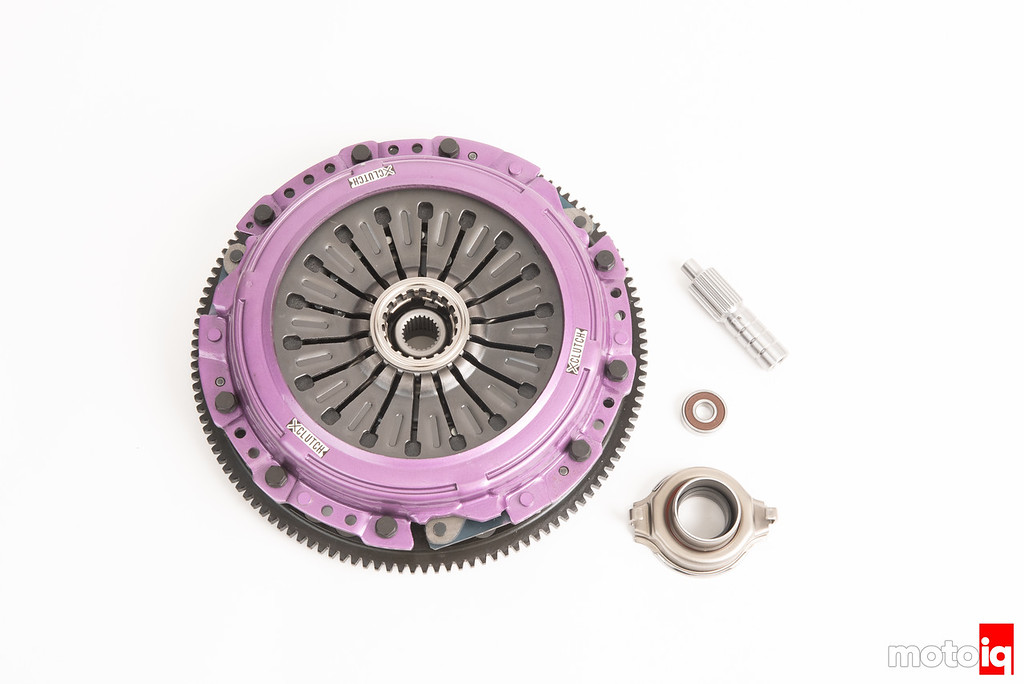

The XClutch has a whole bunch of neat and innovative design features to assure that this is a very streetable design. The first off is that it has two discs. With twin discs, the clamp load that the pressure plate has to provide to get the torque capacity to handle a healthy engine can be lower due to the additional friction ring area that two discs can provide.

Typically a twin-disc clutch is very noisy, the disc and floater plates float and vibrate back and forth when the clutch is disengaged making quite a bit of racket. Another area that lacks refinement is a typical twin-disc clutch that has discs with a solid hub with metallic pucks that make for short engagement travel and a lot of judder with Noisey drivetrain harmonics being fed back into the chassis. If an attempt is made to run sprung hubs, the weight of two sprung hubs is hard on synchros and makes for slow shifts. The thickness of two sprung hubs also adds up in stack height and thus a thick heavy floater plate is needed, not ideal. XClutch gets around this by using an independently sprung hub that drives the discs via splines. This gives the smoothness, quietness, and driveline cushioning of sprung hubs with less inertia and a lower stack height.

The discs themselves have an aramid-reinforced organic friction material. Aramid is the generic name for high-strength stronger than steel fibers like kevlar. The organic material gives smoothness while the Aramid gives abrasion resistance and strength for high burst resistance. The material is bonded and riveted to a lightweight steel backing plate. The clutches’ smoothness comes from the friction characteristics of the material and thus no marcel spring is needed between the friction material and backing plate. With no marcel cushion, the clutch has a quick and clean release for ease on synchros and faster shifting, especially at higher rpm.

10 comments

Does the clutch/flywheel assembly need to be specially balanced? The lugs and lightening holes don’t look at all symmetrical.

Looks like a well designed and made part. I really like the CNC’d lugs.

You can see the balance hole in one of the pictures.

The holes are actually symmetrical

Some really clever solutions to make this clutch the best of many worlds. Love seeing all the detail you provided in the article to explain why decisions were made. Looking forward to hearing some driving impressions!

And surprisingly, I could actually get the same setup for my Volvo if I need a clutch to handle some big power. Not many companies support such an oddball chassis, so that’s kind of exciting.

I was debating on a clutch setup for my Spec-B and I know from experience that the Exidy multiplate is OBNOXIOUS (but works well) I’ve been looking at the X-clutch for some time but after reading this analysis I’ve made up my mind! Now if only you guys hadn’t taken what seems to be the only one left in the country!

Sorry!

Finally got my clutch in, 5 months from date of purchase. What an amazing piece, can’t wait to get going on my project again!

Would you consider the unsprung version of this clutch would be manageable for a daily driven car? Could you kindly explain what differences in driving experience would running an unsprung version yield?

It would not be as smooth with a lot of judder.

I am so glad to have found this website! I’ve ben following you, Mike, since Sport Compact Car and that Nissan Performance web magazine you wrote for way way back. This clutch will most likely go into my bugeye once I destroy my current clutch