,

|

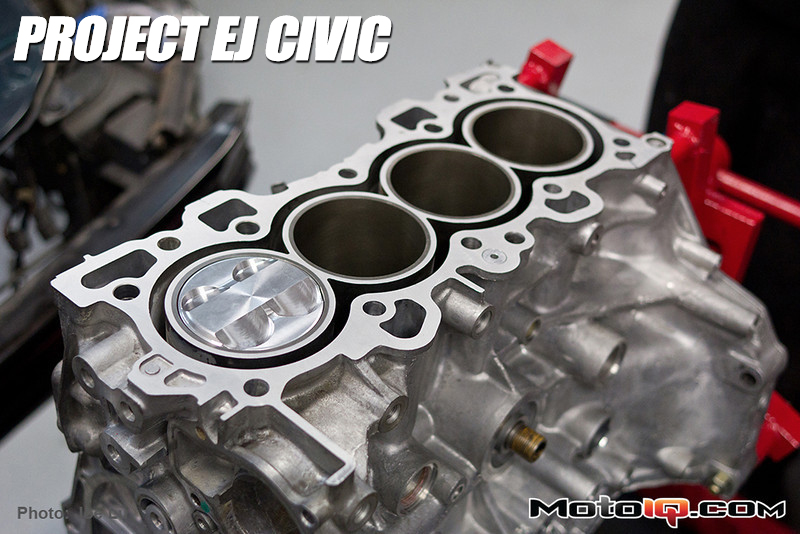

After cleaning the block, we then verified that there was adequate ring gap for each ring. Although our piston rings came from JE Pistons pre-gapped for our 81.5 mm bore, it's still good practice to verify the ring gap before assembling an engine. Too loose of a gap can cause a large amount of power robbing blow by and potentially oil control issues. Too tight of a gap can cause ring butting which can lead to severe ring face wear, loss of tension and seal, and in extreme cases, ring land separation.

With all the formalities now checked off the list, we could finally turn our attention towards the actual assembly of the long rod B18C1 engine. We began by installing a set of high strength ARP main studs and then laying one half of our WPC treated Honda main bearing shells into the main journals. We then dropped our WPC treated factory B18C1 crankshaft in place.

|  |

Although we had previously verified the rod and main bearing clearances using a micrometer, height gauge, and bore gauge, one last check was performed using Sealed Power SPG-1 plastiguage.

|

Since a typical automotive journal type bearing is eccentric in shape, it's important to measure clearances parallel to the crank axis and across the middle of the bearing. The further you measure from the center of the bearing, the larger and more inaccurate your reported clearance will be.

|

| For the final assembly, a generous supply of Lucas assembly lube was applied to the outer surface of the main bearings and thrust bearing faces as well as the crankshaft journals. |

|