,

Here are the four ignition coils bolted to their mounting bracket. The coils are separated vertically far enough away from each other to allow for access to the 5-pin connector on the backside. Nylon lock nuts are used to keep the coils from vibrating loose.

In typical Project RX-7 fashion, threaded inserts were installed into the body of the car. This was necessary because unlike the oil thermostat bracket, there wasn't a good set of existing mounting features for the ignition coils. We also considered the idea of mounting the coils to the engine, but chassis mounted won out through the design process due to less potential vibration and better plug wire routing.

Mounting bracket installed with M6 hardware and ready for ignition coils.

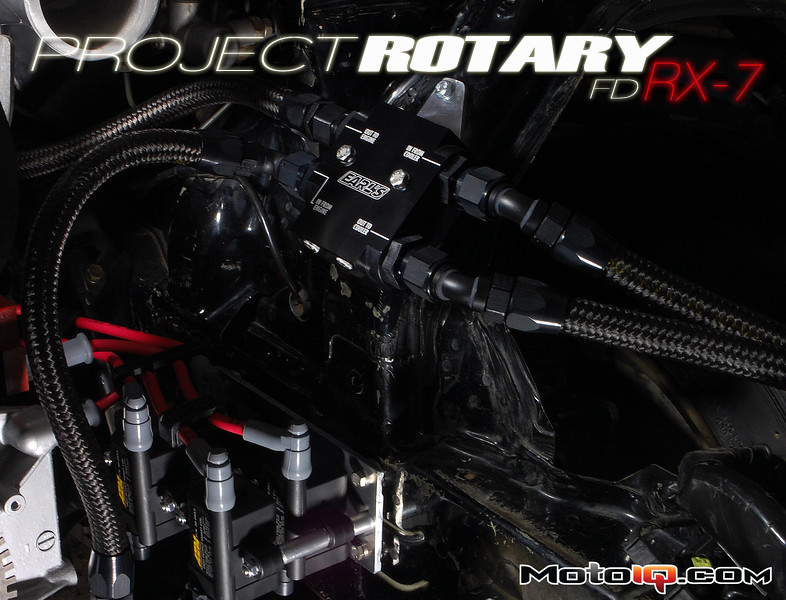

With the ignition coils completely installed we can now begin to route all the oil hoses and spark plug wires that will occupy the same general area in the engine bay. Tackling these two engine systems at the same time was strategic since the design of one can so easily effect the design of the other.

Time to put on the red hat and overalls because once again it's time for one of our favorite parts of building cars…plumbing. A lot of planning is necessary before starting an extensive plumbing job due to the expensive nature of the fittings. We find it best to mount all components before purchasing the hose and fittings to ensure you get the right amount of hose and buy fittings with the correct angles as this can save a ton of money.