,

Earl's Performance Plumbing “Ano-Tuff” black anodized hose ends were used exclusively for the RX-7's oil system. The quality of these -10AN hose ends is incredible. The anodized finish proved to be extremely strong during the mounting (and cough…unmounting) of every single hose.

The Earl's Pro-Lite 350 hose used for the oil system has a nylon over braiding instead of stainless steel which results in ~40% weight savings. While nylon braided hose cannot be used in place of stainless steel braided hose for all applications (less abrasion resistant and lower maximum pressure), it is perfect for the RX-7's oil cooling system.

These two completed hose assembiles are the engine feed and return lines to the oil thermostat. The nylon braiding on the Earl's Pro-Lite 350 hose allows for a very tight bend radius for -10AN hose.

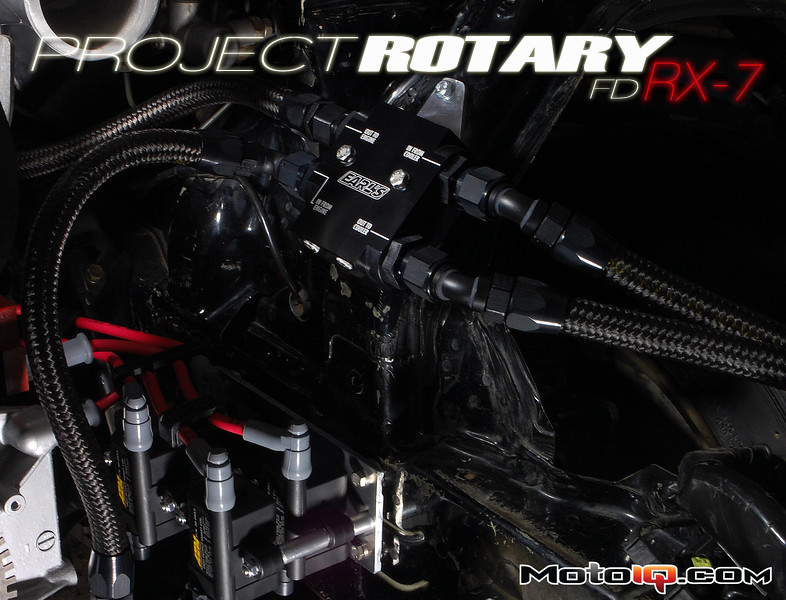

Here the finished oil lines are assembled to the thermostat. It's starting to look more and more like an actual engine rather than just a collection of random parts. Maybe there is a method to this madness after all.

The hoses on the engine side of the thermostat are very short in comparison to those on the cooler side. Notice how the feed hose coming off the engine's front cover has a large arc that clears the ignition system and adds flexibility to allow for movement between the engine and frame. This concern about relative motion is also the reason for the s-bend in the hose that returns the cooled oil to the oil filter pedestal.