,

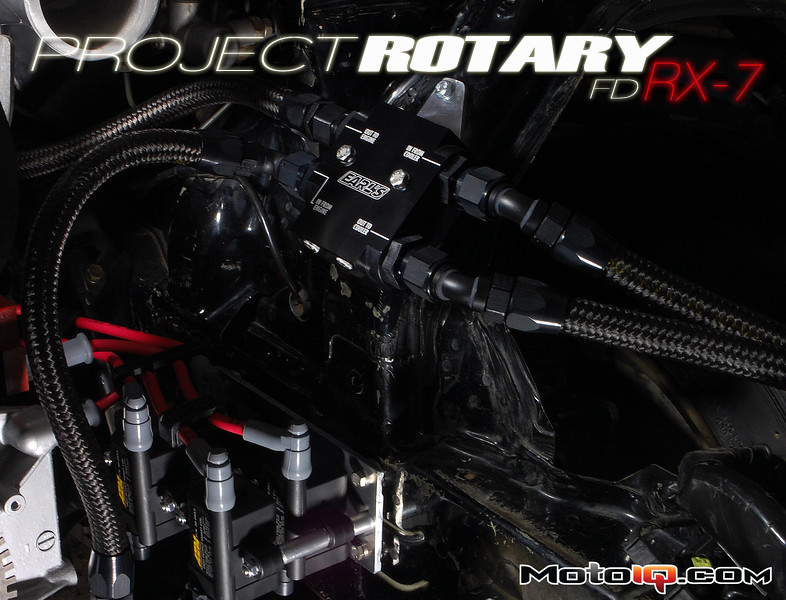

The oil cooler hoses come from the thermostat and pass through the hole in the chassis that used to provide clearance for the headlight motor and lever arm. As much as we love the pop-up lights on the RX-7, this hose routing and a slight weight reduction is worth the conversion to fixed lights.

Rubber coated aluminum p-clips are used again in this build to make sure the hoses stay put and do not cause unwanted problems. Sometimes it's ignoring small details like this that come back to haunt you.

Last thing to do is finish up the igntion system. Now that the oil cooling system is complete and occupying its portion of the engine bay, it's time to focus on the spark plug wiring.

Building our own spark plug wires was pretty much mandatory once we started down the path of custom coil mounting. This is a good thing though because it allows you to choose high quality products. In this case we used MSD 8.5mm Super Conductor wire and 100% silicone coil/plug boots.

Here we have the four assembled spark plug wires. Notice how short we were able to make the wires since we located the ignition coils where we did.

Spark plug wires installed to the ignition coils with the wire separators spaced so that there is a gap between each plug wire for their entire length. Not only does this make for a better looking ignition system, it is also good practice (albeit a bit old school at this point) to reduce any chance of misfires from plug wire to plug wire.