,

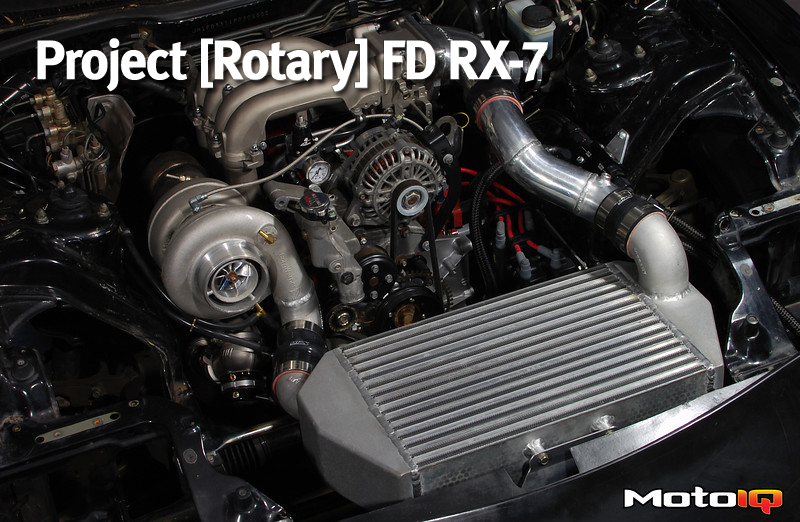

Mounting the intercooler required chassis modifications and quite a bit of custom bracketry. A steel cross-tube and a couple of aluminum brackets were fabricated to hold the rear of the intercooler. The front of the intercooler is held up by part of the chassis and another aluminum bracket. Part of the front bumper mounting surface was removed to make room for the intercooler and a new one will need to be made to replace it in the future.

It's about time we get this beast mounted. Starting up front, two M8 threaded weld bosses were machined and a piece of 0.090″ 5052 aluminum was cut and bent to make the mounting bracket. The bracket is secured to the frame with a couple of M8 rivnuts. Apologies for getting excited and forgetting to take pictures of the steps leading up to this point. Don't worry, we'll make up for it from here on out.

It's about time we get this beast mounted. Starting up front, two M8 threaded weld bosses were machined and a piece of 0.090″ 5052 aluminum was cut and bent to make the mounting bracket. The bracket is secured to the frame with a couple of M8 rivnuts. Apologies for getting excited and forgetting to take pictures of the steps leading up to this point. Don't worry, we'll make up for it from here on out.

Part of this intercooler setup requires the modification of the Borg Warner turbo's compressor housing. Here we have cut off the end of the compressor outlet and tacked on a 2.5″ tight radius cast aluminum elbow from Vibrant Performance.

Part of this intercooler setup requires the modification of the Borg Warner turbo's compressor housing. Here we have cut off the end of the compressor outlet and tacked on a 2.5″ tight radius cast aluminum elbow from Vibrant Performance. The cast elbow completely welded on and the compressor housing reinstalled to the turbo.

The cast elbow completely welded on and the compressor housing reinstalled to the turbo. When you are making parts from scratch you have to start somewhere. This is another piece of 0.090″ 5052 aluminum sheet and will be one of two mounting brackets for the rear of the intercooler. Sections marked with an “X” will be cut away and lines marked with an “X” are where the sheet will be bent.

When you are making parts from scratch you have to start somewhere. This is another piece of 0.090″ 5052 aluminum sheet and will be one of two mounting brackets for the rear of the intercooler. Sections marked with an “X” will be cut away and lines marked with an “X” are where the sheet will be bent.  Skipped a couple of steps, but here we have the cut and bent rear mounting brackets that are ready for welding.

Skipped a couple of steps, but here we have the cut and bent rear mounting brackets that are ready for welding. Rear mounting brackets sitting on the cross-tube while a piece of wood continues to support the intercooler core.

Rear mounting brackets sitting on the cross-tube while a piece of wood continues to support the intercooler core. This shot gives a better idea how the rear mounting brackets attach to the cross-tube. Basically there is a piece of steel channel straddling the tube. After the channel is fully welded to the tube (currently just tacked in the picture) it is drilled and tapped for two M6 bolts per mounting bracket.

This shot gives a better idea how the rear mounting brackets attach to the cross-tube. Basically there is a piece of steel channel straddling the tube. After the channel is fully welded to the tube (currently just tacked in the picture) it is drilled and tapped for two M6 bolts per mounting bracket.

12 comments

Every week I hope for an update. Any hope?

Hope…yes. How much? Not a lot for something soon. Long story short, I moved 2 years ago and the car was in a storage unit in a different state until 2 months ago. Finally have it with me, but currently have very little time to work. The project is still alive, just no where near the top of the priority list at the moment. Keep checking back and you’ll see something eventually :).

How much air should be split between the radiator and the intercooler?

Hi There,

Very nice Build!

I was wondering if you intercooler set up was going to be made available for purchase? or if I was able to purchase some cooler end caps from you.

Thanks

Rob

KISS. What are you building the car to do. looks like you have too much time and money, making the car

look flash but never driving it. looks like you don’t understand the RX-7.Sure there are shortfalls but all with much more cost effective solutions. and yes i do know what i’m talking about. Over 20,000 racing km’s beating factory backed Porsches. NO D.N.F.

Aren’t those NA 20b engines?

13B-REW sequential turbo

13B-REW sequential turbo and raced 1992-1998

Which class in what series and what power output?

I agree with KISS typically, but a 13B-REW sequential turbo probably isn’t going to be competitive in modern day time attack racing, which is what the car was originally being built for. Trying to keep a 450-500hp 13B happy without significant changes to the cooling system (oil, air, and water) is going to be very tough.

Sorry , Not trying to put you down, The car looked more like a show and dyno car. My experience is 450 hp tarmac rally car with competition from Germany backed Porsche 993 turbo 996 turbo . You are right you will have to

modify a few things and if you are serious about time attack maybe not the right place to discuss. i had to develop the car from scratch and was selling parts to mazdaspeed japan at one point and made quite a few mistakes along the way as well , I can see a few things that could help done different. I’m in Australia and no longer race these cars but will defend their underestimated ability i will shut up now . This is your project,

Always enjoyed the direction of this car. Any updates?