The calibration/configuration file(s) (part of a “mod,” in sim racing-speak) contain(s) information about the vehicle dynamics, which includes things like the 3-dimensional coordinates of the suspension pick-up points. When a company that makes a sim wants to add a vehicle, they usually work with the manufacturers to obtain the engineering specifications which have that spatial information. Depending on the sim’s complexity, the information sharing can get into the minutiae of reciprocating mass inertia inside the gearbox. These days, CPUs are so powerful that the calculations required to figure out the physics of individual gears on the overall layshaft are not that “hard,” relatively speaking.

What if you were able to measure, in 3D space, where the suspension pick-up points were on a car? If you could do that, you could make a mod that accurately models a real vehicle within the sim program’s capabilities.

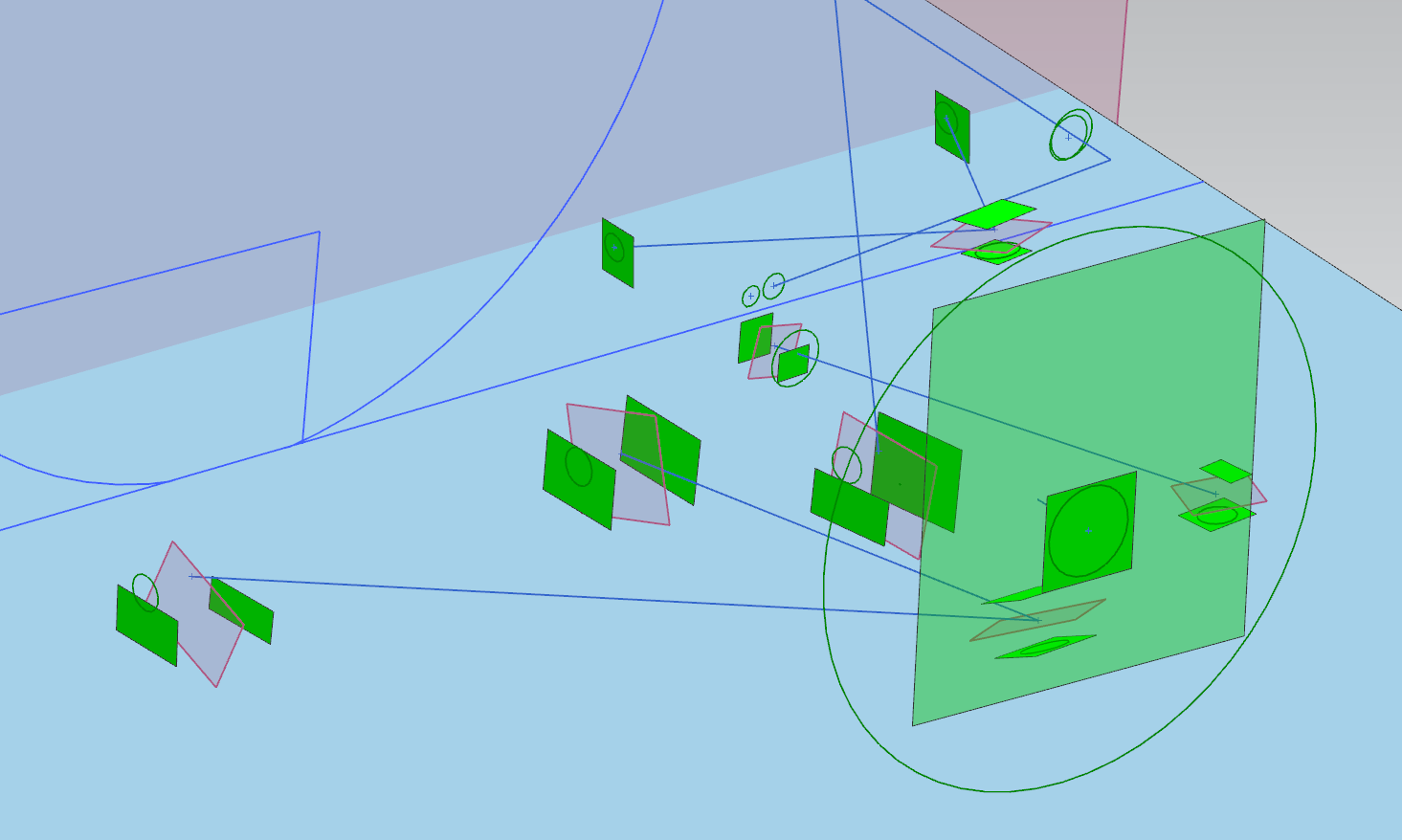

The machine that you see here is called a portable Coordinate Measuring Machine (CMM), often referred to as a CMM arm (because it looks and moves like an arm, I suppose). What does it do? It measures, exceptionally accurately, the 3D spatial coordinates of things. In the case of Project SC300, it would be used to measure where all the suspension points are. The coolest thing? ECM offers rental services for CMM, 3D scanners, and other measuring equipment. I was practically able to just go online and order this thing a’la Amazon shopping, and it showed up at my door with a 2-week rental agreement.

Now, if you’re an average person, you probably don’t need a CMM or a 3D scanner. But many MotoIQ readers are on the shop or manufacturing side of the motorsports industry. If you want to make a part for a car, it can be hard to do it by trial and error or with simple hand tools. If you had a 3D scanner, you could make an accurate model of an entire engine bay to figure out how to create a new intake manifold. You could use a CMM to measure the existing intake manifold mounting holes and bungs and other features and fixtures. You can then make a CAD model of a new thing that lines up with the factory components and have a prototype 3D printed. ECM offers rental services for these measuring devices, and many other companies offer on-demand 3D printing services in materials that even include metals. ECM even has two locations now from which they can ship and certify rental equipment, with a new facility in Wixom, Michigan. You can make $0 long-term capital investment in equipment, make a relatively small rental payment, and then derive value from many tens if not hundreds of thousands of dollars of machinery.

As a shop looking to make parts, when that new Toyota 86 or Ford Bronco or whatever comes out, you can get parts done fast.

ECM makes sure that the accuracy of the CMM is as-promised. They are an ISO/IEC 17025:2017 Accredited Laboratory. That means they have to prove to an external auditor that they are doing things right (accurately and precisely). When dealing with measurement equipment that has promised accuracy on the order of ten-thousandths (0.0001) of an inch or better, it takes a lot of care to properly calibrate. ECM routinely proves to the auditor that they are taking that care so you can be assured that the calibration you’re being shown is real and that the equipment will produce repeatable, precise, and accurate results (within the limits of your capabilities).

If you think about it, you’re trying to measure something in 3D space. The portable CMM arm measures things relative to itself. In other words, you attach the arm to something and move the CMM probe around, and the CMM knows where the end of itself is, so the CMM can then report its position in 3D space. If you don’t attach the arm to a fixed, stable point, you might take a measurement, and then the next measurement is off because the origin moved.

Ideally, you would attach the CMM arm to a really heavy object like a granite table. But for field measurements like this, the base can be made to work.

Not… quite.

11 comments

There’s places that will do tire testing and it’s… expensive but if you keep the test matrix down, in the 4-figures level. Would be interesting to add that to the mix. I’m figuring that most of the time in sims it’s not that the tire model itself has issues, just that it’s filled with variables that people are guessing at.

The most important thing is that the driver understands how the tire develops grip, and how to keep it at the proper temp. You can collect as much data as you want, but if the driver doesn’t understand that data, it is worthless. The pneumatic tire has been around for over a hundred years and there’s only one book written about it? Sad.

This is a must read for anybody serious about racing:

https://www.sae.org/publications/books/content/r-351/

Very interesting, great work Erik! I had no idea this type of equipment could be rented and used by near mortals.

The wheels are turning on other ways this type of equipment could be used.

@Dan: Where / who does the tire testing? I do have a spare that I could trash…

@Erik L: Oh yeah? What are you thinking of measuring/scanning?

Calspan does – if you are willing to be flexible on schedule and don’t get too complicated it helps hold the cost down, and the gent I was talking to was willing to deal with it as a smaller project.

Dan – if you find me on Facebook or email me at erikmjacobs (gmail) would you tell me who you spoke with? I’d be curious to talk to that person.

Mailed. Though as I mention in the email I just used the contact form at https://www.calspan.com/contact/ and they got back to me in a couple days.

Great article of the process. Well done.

Thanks Brad!

Yeah, I really like this article. I wrote my own code in MATLAB in college using Dixon’s equations and precise measurements (by hand) of the EG6 Civic suspension. I had so many parts lying around, it was pretty much a no brainer. You can learn how to avoid so many mistakes through simulation. While I did some minor modifications using a LCON traction bar which allowed me to remove the rear half of the LCA, and drop 8lbs of unsprung weight, I also gained enormous appreciation for Honda suspension engineers. The stock bump steer curve could not actually be improved upon without new spindles. Simulation proved to me that some things are better left alone.

This is a great book, BTW. It is the ‘Bible’ for suspension engineers.

https://www.wiley.com/en-us/Suspension+Geometry+and+Computation-p-9780470510216

Thanks, Joe! That looks like a real textbook there. Probably well over my head. As you’ve learned some things are best left alone, I have learned that for some things I should probably outsource. Suspension engineering is one of those things. I’m fortunate to have folks like Figs Engineering, Mike Kojima, and Rob Lindsey (Morlind Engineering) available to me!