Since road cars are generally symmetrical (circle-track cars may actually have an asymmetrical chassis), establishing the centerline helps you know how far the suspension is offset from the center of the vehicle.

First, pick two (hopefully) symmetrical points on the front of the car and transfer them to the ground using the plumb bob. Here I used the bolt holes on the front frame rail where the front bumper would attach. Since the frame rails are probably the most symmetrical thing on the car, this is a good bet.

On an old, beat up chassis, are they going to be perfectly symmetrical? Highly unlikely. Is this the best bet you can make given all of the other variables and circumstances? Yes.

Just because the CMM says that the measured point is at X, Y, Z coordinate, the question is really where that coordinate is in relation to the vehicle itself, not where it is with the CMM machine as the origin.

You need to “measure”/calibrate the coordinate system every time you start taking measurements to establish the known vehicle reference point. You noticed that my car was near the ground. The CMM arm is long, and they make longer ones, but it’s not long enough to reach under the car to the center.

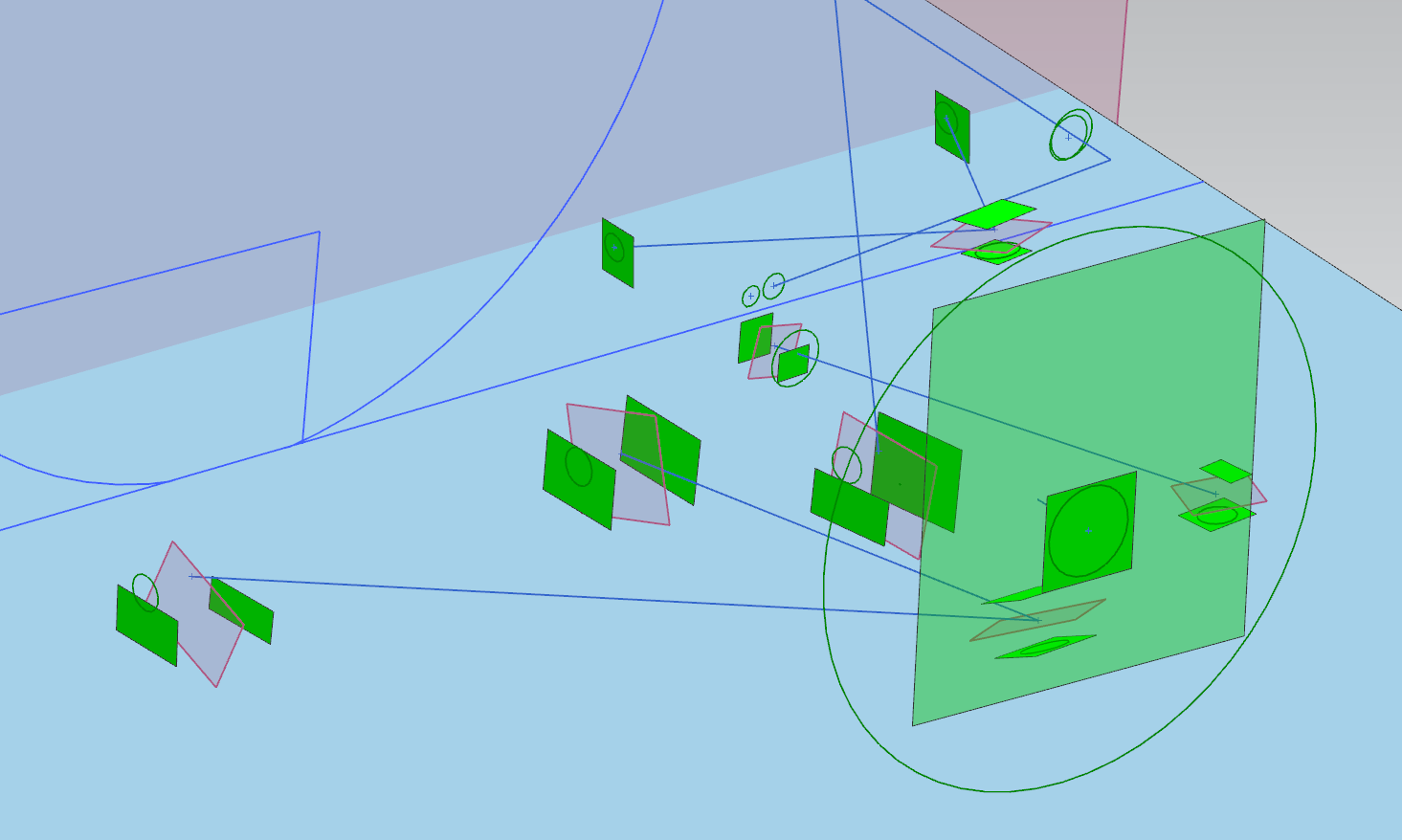

Here we have mapped a point 4 feet away from the vehicle centerline. This is at the front of the vehicle. We will then repeat this measure-symmetry-center-point-offset procedure near the back of the car to establish a rear center point and a rear 4-foot point.

Connect the dots on the front and rear 4-foot points, and you now have a line that is a known offset from the actual vehicle center line that is also easy to access with the CMM.

I didn’t want to take off the rear bumper, so I used the inner rear lower control arm bolt holes as my reference points for finding the rear center point. One could argue this isn’t smart because the subframe may be offset from the vehicle due to bushing wear or etc. You’re not going to do much better than this, though.

If the subframe is offset and you measure the chassis center, you’re still ending up measuring the offset of the subframe somehow when you measure the suspension. Seems like six-of-one / half-dozen-of-another to me. There’s lots of slop in all of this process. The goal is to simply minimize the slop as well as is possible within reason.

11 comments

There’s places that will do tire testing and it’s… expensive but if you keep the test matrix down, in the 4-figures level. Would be interesting to add that to the mix. I’m figuring that most of the time in sims it’s not that the tire model itself has issues, just that it’s filled with variables that people are guessing at.

The most important thing is that the driver understands how the tire develops grip, and how to keep it at the proper temp. You can collect as much data as you want, but if the driver doesn’t understand that data, it is worthless. The pneumatic tire has been around for over a hundred years and there’s only one book written about it? Sad.

This is a must read for anybody serious about racing:

https://www.sae.org/publications/books/content/r-351/

Very interesting, great work Erik! I had no idea this type of equipment could be rented and used by near mortals.

The wheels are turning on other ways this type of equipment could be used.

@Dan: Where / who does the tire testing? I do have a spare that I could trash…

@Erik L: Oh yeah? What are you thinking of measuring/scanning?

Calspan does – if you are willing to be flexible on schedule and don’t get too complicated it helps hold the cost down, and the gent I was talking to was willing to deal with it as a smaller project.

Dan – if you find me on Facebook or email me at erikmjacobs (gmail) would you tell me who you spoke with? I’d be curious to talk to that person.

Mailed. Though as I mention in the email I just used the contact form at https://www.calspan.com/contact/ and they got back to me in a couple days.

Great article of the process. Well done.

Thanks Brad!

Yeah, I really like this article. I wrote my own code in MATLAB in college using Dixon’s equations and precise measurements (by hand) of the EG6 Civic suspension. I had so many parts lying around, it was pretty much a no brainer. You can learn how to avoid so many mistakes through simulation. While I did some minor modifications using a LCON traction bar which allowed me to remove the rear half of the LCA, and drop 8lbs of unsprung weight, I also gained enormous appreciation for Honda suspension engineers. The stock bump steer curve could not actually be improved upon without new spindles. Simulation proved to me that some things are better left alone.

This is a great book, BTW. It is the ‘Bible’ for suspension engineers.

https://www.wiley.com/en-us/Suspension+Geometry+and+Computation-p-9780470510216

Thanks, Joe! That looks like a real textbook there. Probably well over my head. As you’ve learned some things are best left alone, I have learned that for some things I should probably outsource. Suspension engineering is one of those things. I’m fortunate to have folks like Figs Engineering, Mike Kojima, and Rob Lindsey (Morlind Engineering) available to me!